Water-based release agent for color printing and paper adhesive tapes and preparation method thereof

A water-based release and paper tape technology, which is applied in the direction of adhesives, coatings, film/sheet release liners, etc., can solve the problems of poor release, inability to stick on the back, difficulty in unwinding, etc., and achieves simple steps and convenient operation , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

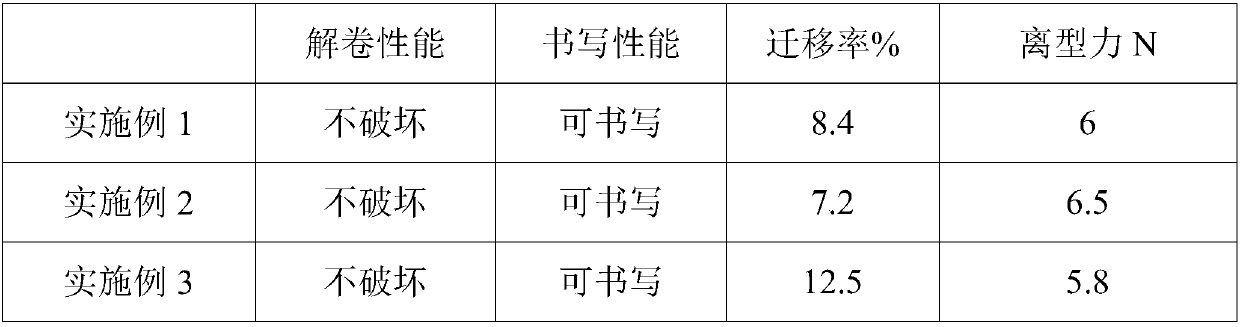

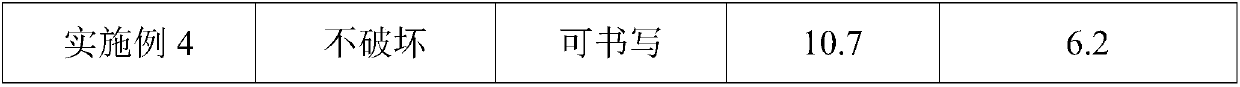

Examples

Embodiment 1

[0020] First, mix the mixture of 4kg vinyl acrylate and hydrogen-containing silicone oil emulsion with 10kg deionized water for 15 minutes until uniform, and dilute the hydrogen-containing silicone oil modifier to facilitate the cross-linking of the hydrogen-containing silicone oil emulsion; Mix well and add 0.16 kg of chloroplatinic acid additive to the diluted hydrogen-containing silicone oil modifier and stir together for 3 minutes until uniform to obtain a uniformly dispersed interface modifier, and add it to the mixture of hydrogen-containing silicone oil modifier and platinum additive Add 0.01 kg of antifoaming agent polydimethylsiloxane to the mixture for defoaming; finally, add 100 kg of silicon-modified polyvinyl acetate emulsion to the diluted interface modifier and stir together for 10 minutes until uniform. After the silicon-modified polyvinyl acetate emulsion is mixed, the interface modifier can be cross-linked on the surface of the silicon-modified polyvinyl aceta...

Embodiment 2

[0022] First, mix 10kg of vinyl acrylate, hydrogen-containing silicone oil emulsion and 30kg of deionized water for 30 minutes until uniform. And add 0.4 kg of chloroplatinic acid complex additive to the diluted hydrogen-containing silicone oil modifier and stir together for 5 minutes until uniform, to obtain a uniformly dispersed interface modifier, and add the hydrogen-containing silicone oil modifier and platinum additive Add 0.02kg of a mixture of antifoaming agent polydimethylsiloxane and polyoxypropylene glyceryl ether to the mixture for defoaming; finally, add 200kg of silicon-modified polyvinyl acetate emulsion to the diluted interface modifier and stir together for 20 Minutes to uniformity, under the catalysis of chloroplatinic acid additives, the interface modifier can cross-link silicon-modified polyvinyl acetate emulsion to form a very thin silicone oil layer, which can be used for color printing and paper after discharge. Water-based release agent, all the stirrin...

Embodiment 3

[0024] First, mix 10kg of vinyl acrylate, hydrogen-containing silicone oil emulsion mixture with 30kg of deionized water and stir for 25 minutes until uniform. Add 0.4 kg of chloroplatinic acid complex additive to the homogeneous and diluted hydrogen-containing silicone oil modifier, and stir together for 5 minutes until uniform, to obtain a uniformly dispersed interface modifier, and add the hydrogen-containing silicone oil modifier and platinum Add 0.02 kg of defoamer polyoxypropylene glyceryl ether to the mixture of additives for defoaming; finally, add 200 kg of silicon-modified polyvinyl acetate emulsion to the diluted interface modifier and stir together for 20 minutes until uniform, and the interface modifier Under the catalysis of chloroplatinic acid additives, it can be cross-linked on the surface of silicon-modified polyvinyl acetate emulsion to form a very thin silicone oil layer. After discharging, it can be used as a water-based release agent for color printing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com