Chromium-containing oxide-carbide composite coating and preparation method thereof

A composite coating and carbide technology, which is used in the design and preparation of ultra-high temperature ablation-resistant oxide-carbide composite coatings, which can solve the problem of difficult matching of thermal expansion coefficients, fast ablation loss at high temperature, and low ablation resistance temperature. problem, to achieve the effect of improving mechanical properties, improving bonding strength, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

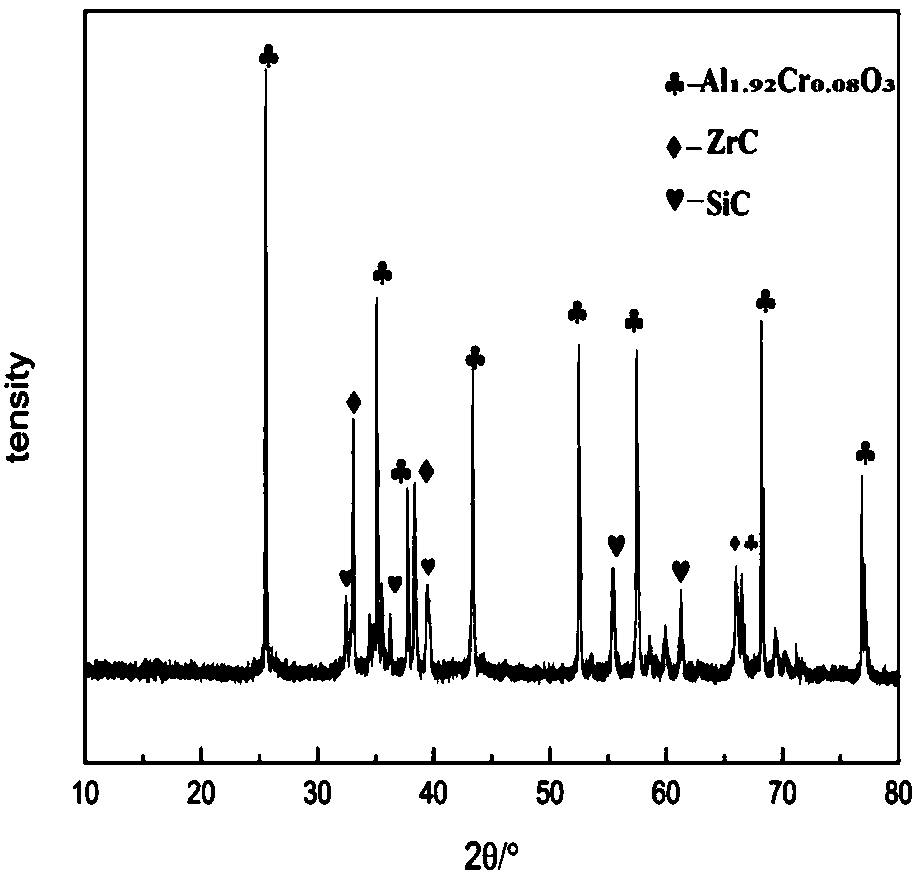

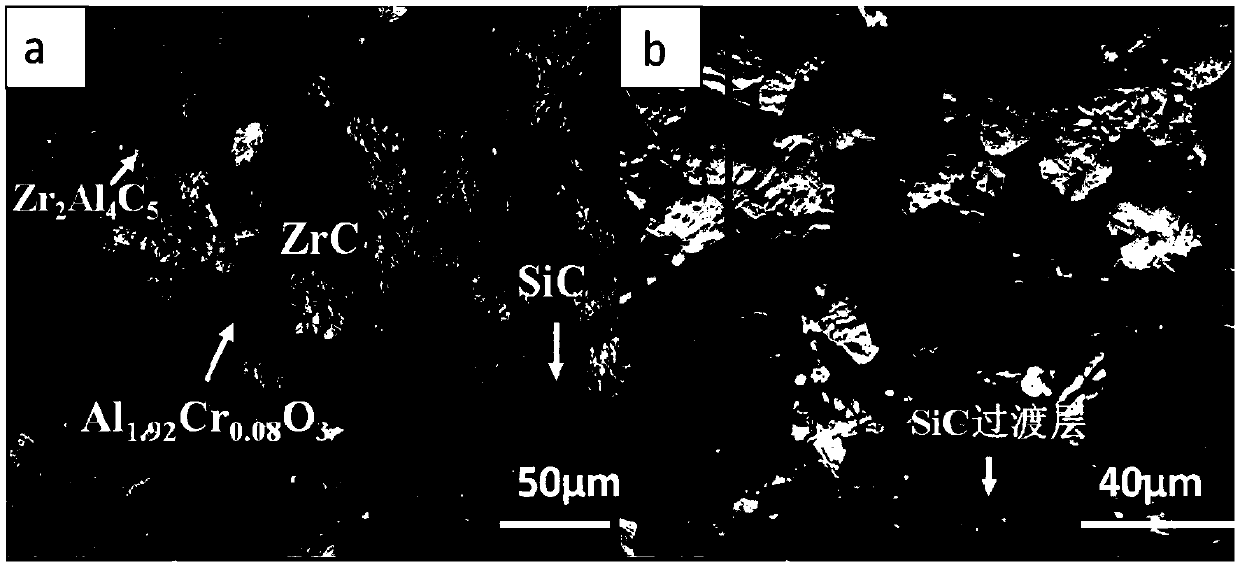

[0051] First, use the reaction infiltration method to 1.4g / cm 3 Around the porous carbon / carbon composites undergo matrix modification. The porous carbon-carbon composite material is machined and cut into of samples. Then put the zirconium and silicon powders into the graphite crucible together with the porous carbon-carbon composite material sample after ball milling, drying and sieving, and infiltrate in a high-temperature furnace. The treatment temperature is 2000°C, the holding time is 2 hours, the heating rate is 10°C / min, and the cooling rate is 5°C / min. After 100°C, it is naturally cooled with the furnace, and the whole process is protected by argon.

[0052] Next, the surface treatment of the modified C / C-ZrC-SiC composite material sample obtained by infiltration was carried out by ultrasonic cleaning, and then the sample was dried in a vacuum drying oven as a matrix material for later use.

[0053] Then, Zr-Si-Al-Cr-C five kinds of elemental powders were weighed a...

Embodiment 2

[0059] The low-density porous carbon / carbon composite material is placed in a graphite tank filled with zirconium and silicon powder, and heat-treated in a high-temperature furnace to complete the infiltration process to obtain a modified C / C-ZrC-SiC composite material. Mechanically process it into a 100×100×30mm sample, then use an ultrasonic cleaner to clean it in ethanol solution for 1 hour, and dry it in a vacuum drying oven for later use.

[0060] Then the five elemental powders of Zr-Si-Al-Cr-C were weighed and mixed according to the molar ratio of 3:2:4:1:9, and then ball-milled on a high-energy planetary ball mill for 20 hours. The ball-milling speed was 300r / min. is 5, and the ball milling medium is ethanol solution. The obtained mixed powder is dried in a vacuum drying oven and passed through a 325-mesh sieve, and stored in isolation from air.

[0061] Then weigh a certain amount of polyvinyl butyral powder and dissolve it in the ethanol solution at a ratio of 1:50,...

Embodiment 3

[0065] The preparation process and process parameters are as follows: five kinds of elemental powders of Zr-Si-Al-Cr-C are weighed and mixed according to the molar ratio of 4:3:4:1:10, and then ball milled on a high-energy planetary ball mill for 20 hours, and the ball milling speed is 300r / min, the ball-to-material ratio is 5, and the ball milling medium is ethanol solution. The obtained mixed powder is dried in a vacuum drying oven and passed through a 325-mesh sieve, and stored in isolation from air. Plasma spraying process parameters: sealed chamber pressure 30kpa, powder feeding rate 23g / min, main air flow 80L / h, auxiliary air flow 30L / h, plasma power 50kw, spray 60 times, spray distance 0.20m. The sintering process is held at 1600° C. for 1 hour. Other steps are the same

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com