Preparation method of high-purity nano-structure ZnGa2O4 for deep ultraviolet extremely week light detection

A nanostructure, extremely weak light technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of shortening the reaction period, lowering the activation energy, long reaction period, etc., and achieves controllable morphology and crystallinity. Good, short response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

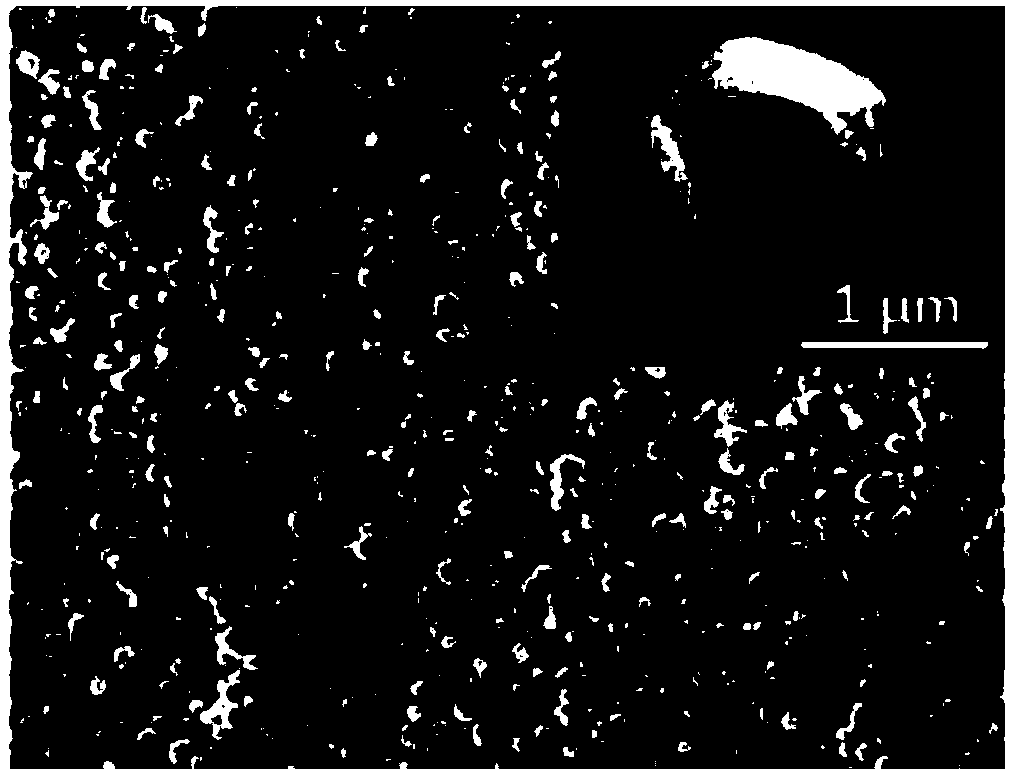

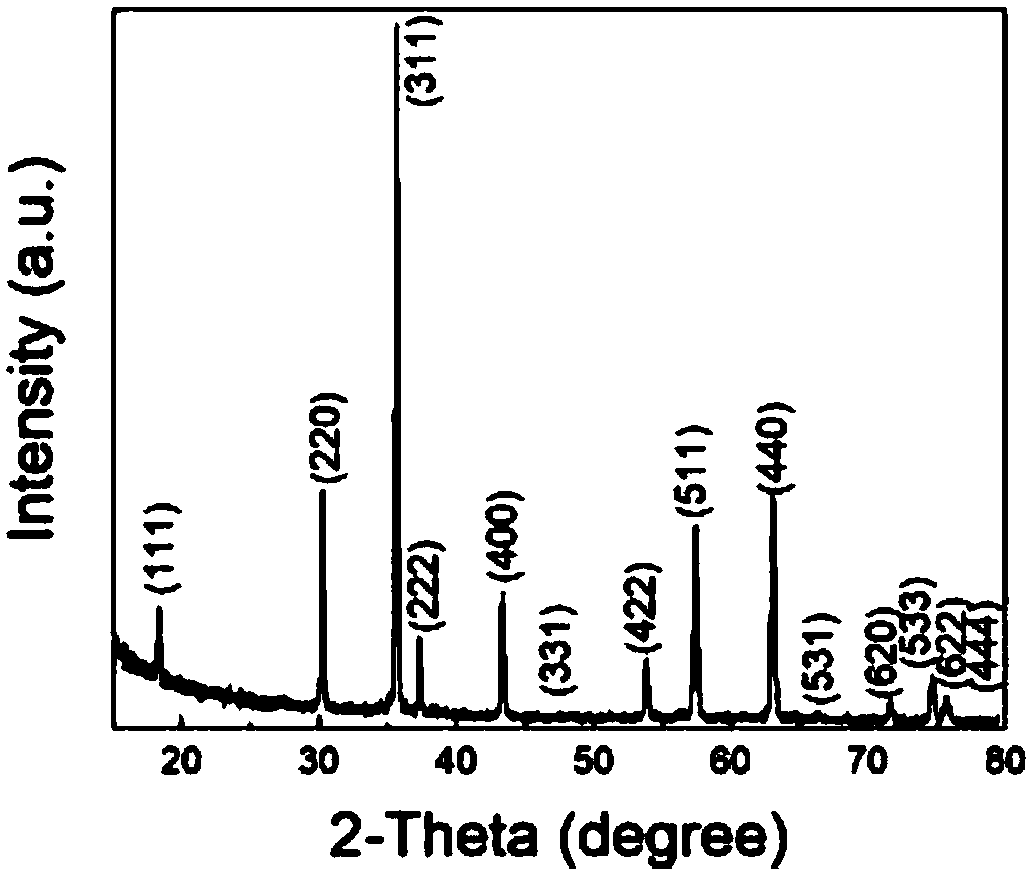

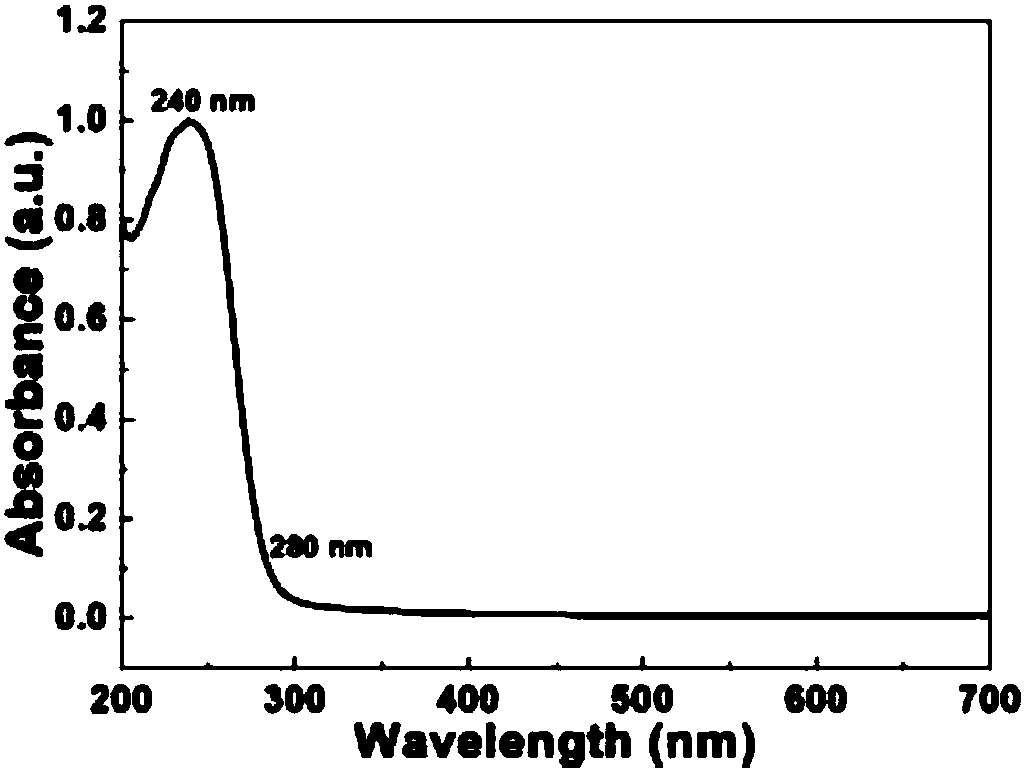

[0030] A high-purity nanostructure ZnGa that can be used for deep ultraviolet extremely weak light detection of the present invention 2 o 4 The preparation method uses liquid-phase laser ablation and solvothermal method to combine liquid-phase laser ablation of high-purity targets (zinc target and gallium oxide target) immersed in the solution to obtain highly active solvothermal precursors. Nanostructured ZnGa with high purity, single phase structure, good crystallinity, and uniform and controllable morphology was synthesized by solvothermal method under milder conditions. 2 o 4 . By changing the laser ablation time, the amount of deionized water and auxiliary agents (glacial acetic acid, ammonia water), reaction temperature, and reaction time, high-purity nanostructured ZnGa with different sizes and shapes can be obtained. 2 o 4 , including the following steps:

[0031] Step 1. Add deionized aqueous solution to the reaction vessel, place the gallium oxide target in deio...

Embodiment 1

[0042] Using the combination of liquid-phase laser ablation and solvothermal method, the high-purity target (zinc target and gallium oxide target) immersed in the solution is obtained by liquid-phase laser ablation to obtain a highly active solvothermal precursor. High-purity nanostructured ZnGa with single-phase structure, good crystallinity, uniform size and controllable morphology was synthesized under milder conditions 2 o 4 . Specific steps are as follows:

[0043] Step 1. Add 60mL of deionized aqueous solution to the reaction vessel, place the gallium oxide target in deionized water, and use a magnetic stirrer to keep uniformly stirring the solution;

[0044] Step 2. Adjust the optical path of the pulsed laser beam of the Nd:YAG solid-state laser so that the laser beam is focused on the junction of the liquid surface of the deionized water and the gallium oxide target, and ablate the gallium oxide target immersed in the solution for 80 minutes, with a pulse frequency o...

Embodiment 2

[0052] Using the combination of liquid-phase laser ablation and solvothermal method, the high-purity target (zinc target and gallium oxide target) immersed in the solution is obtained by liquid-phase laser ablation to obtain a highly active solvothermal precursor. High-purity nanostructured ZnGa with single-phase structure, good crystallinity, uniform size and controllable morphology was synthesized under milder conditions 2 o 4 . Specific steps are as follows:

[0053] Step 1. Add 60mL deionized aqueous solution to the reaction vessel, place the gallium oxide target in deionized water, and use a magnetic stirrer to keep uniformly stirring the solution;

[0054] Step 2. Adjust the optical path of the pulsed laser beam of the Nd:YAG solid-state laser so that the laser beam is focused on the junction of the liquid surface of the deionized water and the gallium oxide target, and ablate the gallium oxide target immersed in the solution for 90 minutes, with a pulse frequency of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com