Low-energy-consumption high-yield method for preparing hydrogen from raw gas

A raw gas, high-yield technology, applied in chemical instruments and methods, sulfur preparation/purification, hydrogen, etc., can solve the problems of combustible gas waste in the analysis gas, low hydrogen yield, analysis gas treatment, etc., to achieve protection Adsorbent, reduce investment, effect of desulfurization and deoxidation adsorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

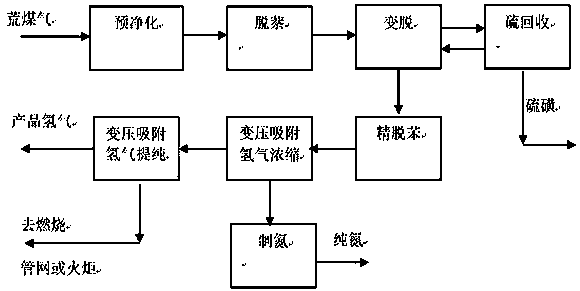

[0054] Such as figure 2 As shown, a low energy consumption, high yield raw gas hydrogen production process, followed by the following operations:

[0055] 1) Pre-purification: The raw gas from the gas cabinet is pressurized to 30kpa by the fan, enters from the lower part of the washing tower, contacts with the washing liquid countercurrently, and enters the electrostatic coke catcher after being washed. More than 93% of the tar is removed, and the tar content is about 50mg / m3.

[0056] 2) Naphthalene removal: The pre-purified raw coal gas is compressed to 0.3MPag in one stage, and enters the naphthalene removal unit from the bottom of the naphthalene removal tower. The naphthalene removal unit is composed of 4 purification towers and 1 regeneration heater; 2 of which are adsorption towers It is in the state of adsorption, and the rest of the adsorption towers are in the state of regeneration. The adsorption tower is operated alternately to ensure the continuous entry of raw...

Embodiment 2

[0064] Such as image 3 As shown, a low energy consumption, high yield raw gas hydrogen production process, followed by the following operations:

[0065] The raw gas from the gas cabinet is pressurized to 30kpa by the fan, washed by the water washing tower and then enters the electrostatic coke catcher. More than 93% of the tar is removed, and the tar content is about 50mg / m3. After one-stage compression to 0.5MPag, it enters the naphthalene removal unit from the bottom of the naphthalene removal tower. The naphthalene removal unit is composed of 3 purification towers and 1 regeneration heater; 1~2 adsorption towers are in the adsorption state, and the rest of the adsorption towers are in the regenerative state. The adsorption tower is operated alternately to ensure the continuous entry of raw gas; after naphthalene removal, the naphthalene content is less than 20mg / m3. Then through two-stage compression to 1.0MPag, it enters the process of shifting and degassing. It is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com