Preparation method and product of self-supporting VO2 Fenton-like catalytic material

A catalytic material, VO2 technology, applied in the field of preparation of self-supporting VO2-like Fenton catalytic materials, to achieve the effect of good effect, simple preparation process and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

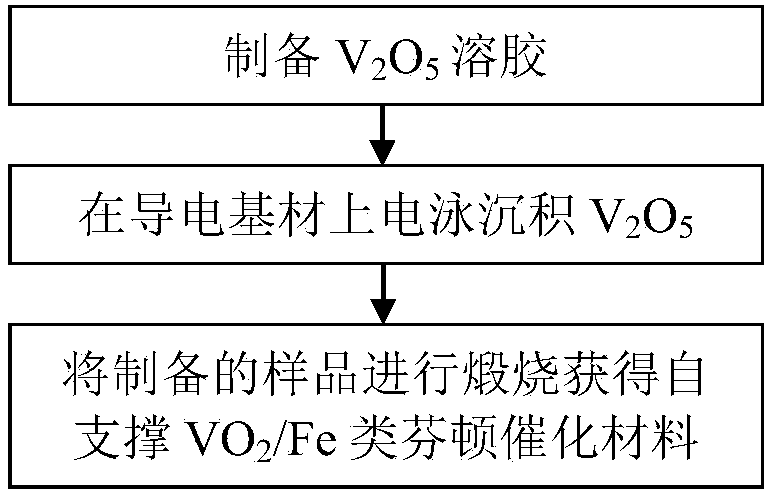

[0043] Such as figure 1 shown, first, the V 2 o 5 The powder is heated to a molten state, and V is prepared by water quenching 2 o 5 Sol, the concentration is 10g / L, aged for 3 days; the circular steel mesh is used as the cathode, and the platinum sheet is used as the anode, installed in the electrophoretic deposition equipment, immersed in the sol, the DC power supply voltage is set to 0.001V, and the distance between the electrodes is 10mm. Time 10min, get V 2 o 5 Coated steel mesh substrate; put the prepared sample in a tube furnace, set the heating rate at 3°C / min, calcining at 700°C, holding time for 1h, and calcining under the atmosphere of 1L / min flow rate to obtain VO 2 Fenton-like catalytic materials. The SEM photo of the catalytic material prepared in this embodiment is as follows image 3 shown.

Embodiment 2

[0045] Such as figure 1 shown, first, the V 2 o 5 The powder is heated to a molten state, and V is prepared by water quenching 2 o 5 Sol, the concentration is 10g / L, aged for 3 days; the circular steel mesh is used as the cathode, and the platinum sheet is used as the anode, installed in the electrophoretic deposition equipment, immersed in the sol, the DC power supply voltage is set to 0.001V, and the distance between the electrodes is 10mm. Time 10min, get V 2 o 5 Covered steel mesh substrate. Put the prepared sample in a tube furnace, set the heating rate at 3°C / min, calcining at 700°C, holding time for 2h, and calcining under the atmosphere of 1L / min flow rate to obtain VO 2 Fenton-like catalytic materials. The SEM photo of the catalytic material prepared in this embodiment is as follows Figure 4 shown.

Embodiment 3

[0047] Such as figure 1 shown, first, the V 2 o 5 The powder is heated to a molten state, and V is prepared by water quenching 2 o 5 Sol, the concentration is 10g / L, aged for 3 days; the circular steel mesh is used as the cathode, and the platinum sheet is used as the anode, installed in the electrophoretic deposition equipment, immersed in the sol, the DC power supply voltage is set to 0.001V, and the distance between the electrodes is 10mm. Time 10min, get V 2 o 5 Coated steel mesh substrate; put the prepared sample in a tube furnace, set the heating rate to 3°C / min, calcining temperature to 700°C, holding time to 3h, and flow rate to 1L / min. get VO 2 Fenton-like catalytic materials. The SEM photo of the catalytic material prepared in this embodiment is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com