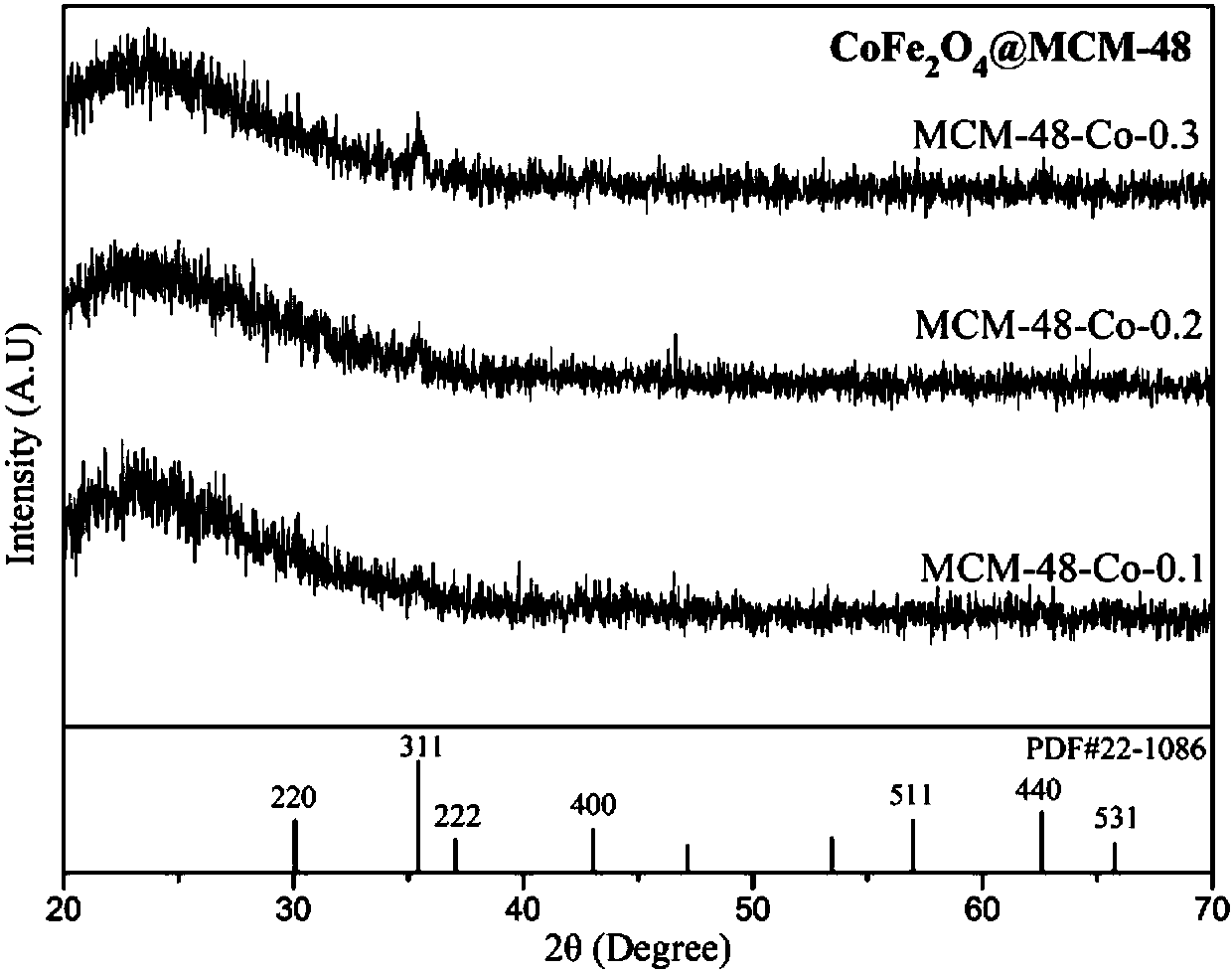

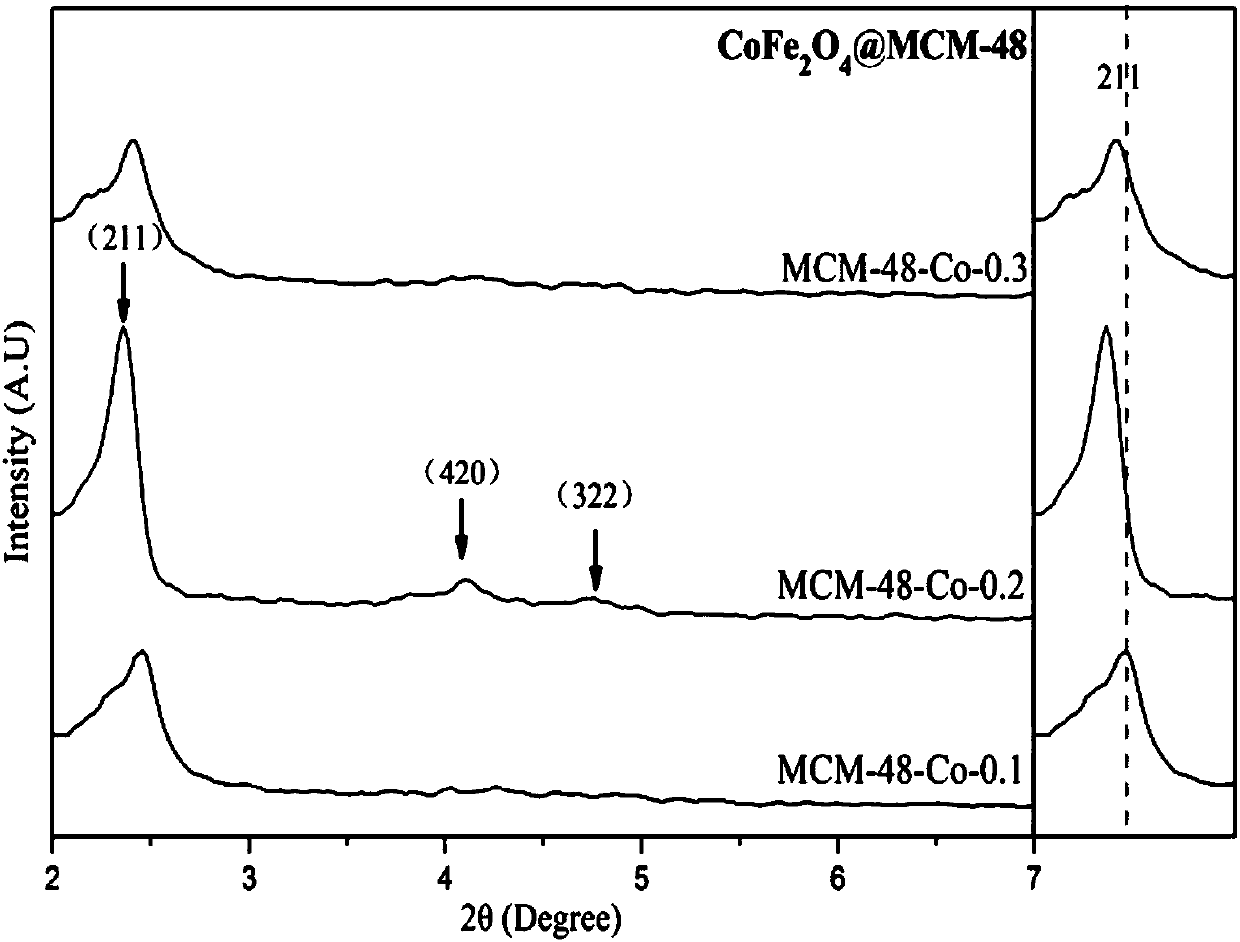

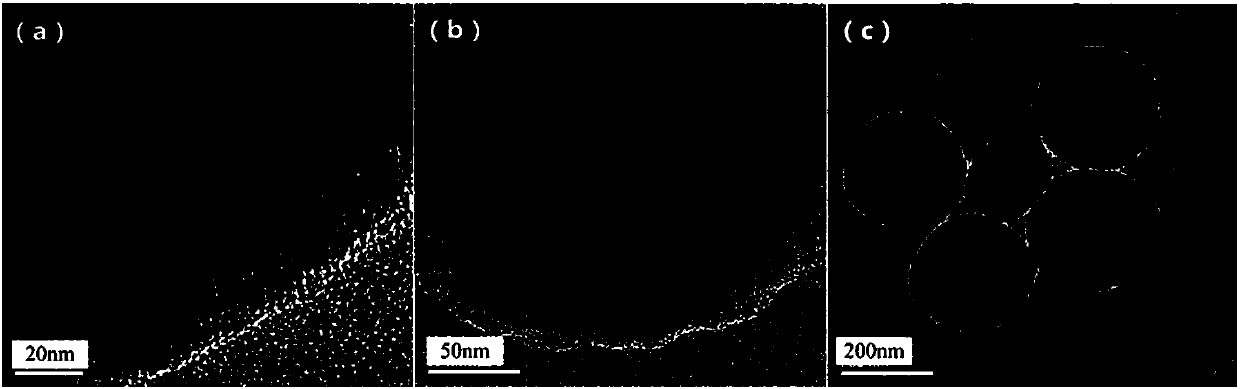

Preparation method of CoFe2O4-at-MCM-48 magnetic mesoporous material of core shell structure

A technology of mesoporous materials and core-shell structure, which is applied in the field of preparation of magnetic mesoporous materials with core-shell structure CoFe2O4@MCM-48, can solve the problems of harsh synthesis conditions, high energy consumption and high cost, and achieve unique magnetic characteristics, The effect of large specific surface area and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A kind of CoFe with core-shell structure provided by the invention 2 o 4 The preparation method of @MCM-48 magnetic mesoporous material comprises the following steps:

[0045] S1, take CoFe 2 o 4 Dissolve in chloroform, ultrasonic 10 ~ 20min, to get a mixed solution;

[0046] S2, take the mixed solution obtained in S1 and add it to the aqueous solution containing cetyltrimethylammonium bromide, continue ultrasonic stirring for 3-8 minutes, raise the temperature of the solution to 50-70°C, and then continue to evaporate for 1-3 minutes , a solution of ferrite particles was obtained; the cetyltrimethylammonium bromide used in S2 was combined with the CoFe used in S1 2 o 4 The ratio is 0.0005mol:0.1g;

[0047] S3, take the ferrite particle solution obtained in S2 and add it to cetyltrimethylammonium bromide-ethylene glycol-water solution, and stir for 5-15 minutes; then add ammonia water to adjust the pH to 11, and then add absolute ethanol, Continue to stir; then a...

Embodiment 1

[0051] A kind of CoFe with core-shell structure 2 o 4 The preparation method of @MCM-48 magnetic mesoporous material, the specific steps are as follows:

[0052] S1, take 0.2g ferrite CoFe 2 o 4 Dissolve in 3ml of chloroform, 400W ultrasound for 15min, to get a mixed solution; CoFe is used here 2 o 4 nanoparticles;

[0053] S2, take half the volume of the mixed solution obtained in S1 and add it to 25ml of 0.8g / 100ml cetyltrimethylammonium bromide (CTAB) aqueous solution (that is, add 0.0005molCTAB), continue 400W ultrasonic stirring for 5min, and The temperature of the solution was raised to 60°C, and then continued to evaporate for 2 minutes to remove the organic chloroform. At this time, a surfactant-stabilized ferrite particle solution was obtained, and the ferrite particles showed hydrophilicity;

[0054] S3, take the ferrite particle solution obtained in S2 and add it to 62g of cetyltrimethylammonium bromide-ethylene glycol-water solution, stir for 10min; then add ...

Embodiment 2

[0058] A kind of CoFe with core-shell structure 2 o 4 The preparation method of @MCM-48 magnetic mesoporous material, the specific steps are the same as in Example 1, the only difference is the CoFe used in S1 2 o 4 The mass is 0.1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com