Sintering tool for planetary gear

A planetary gear and tooling technology, applied in the field of powder metallurgy, can solve the problems of reducing product quality, increasing the internal stress of planetary gears, and not controlling the number of multi-layer superimposed planetary gears, so as to achieve the effect of improving the qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0019] Such as figure 1 The one shown results in a greatly increased internal stress on the planetary gear at the bottom during the sintering process, reducing the quality of the product.

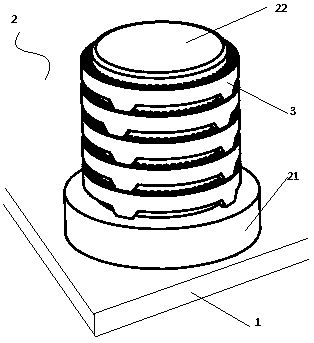

[0020] In order to solve the above technical problems, the technical solution of the present invention is: a planetary gear sintering tool, on which the planetary gear is nested; including a bottom plate 1 and a gear assembly platform 2, and the gear assembly platform 2 is vertically arranged on the bottom plate 1 ; Planetary gear 3 sintered tooling can be stacked on each other.

[0021] The gear assembly platform 2 includes a mounting platform 21 and a sleeve rod 22; the sleeve rod 22 is vertically installed on the mounting platform 21, and the mounting platform 21 and the sleeve rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com