Graphene-titanium dioxide aerogel composite material and preparation and application thereof

A technology of titanium dioxide and composite materials, applied in nanotechnology for materials and surface science, electrical components, active material electrodes, etc., can solve the large volume change of sulfur electrodes with low electronic conductivity of sulfur and hinder the commercialization of lithium-sulfur batteries Development and application, deterioration of battery performance and other issues, to achieve good application prospects, improve electrochemical performance, and stabilize cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

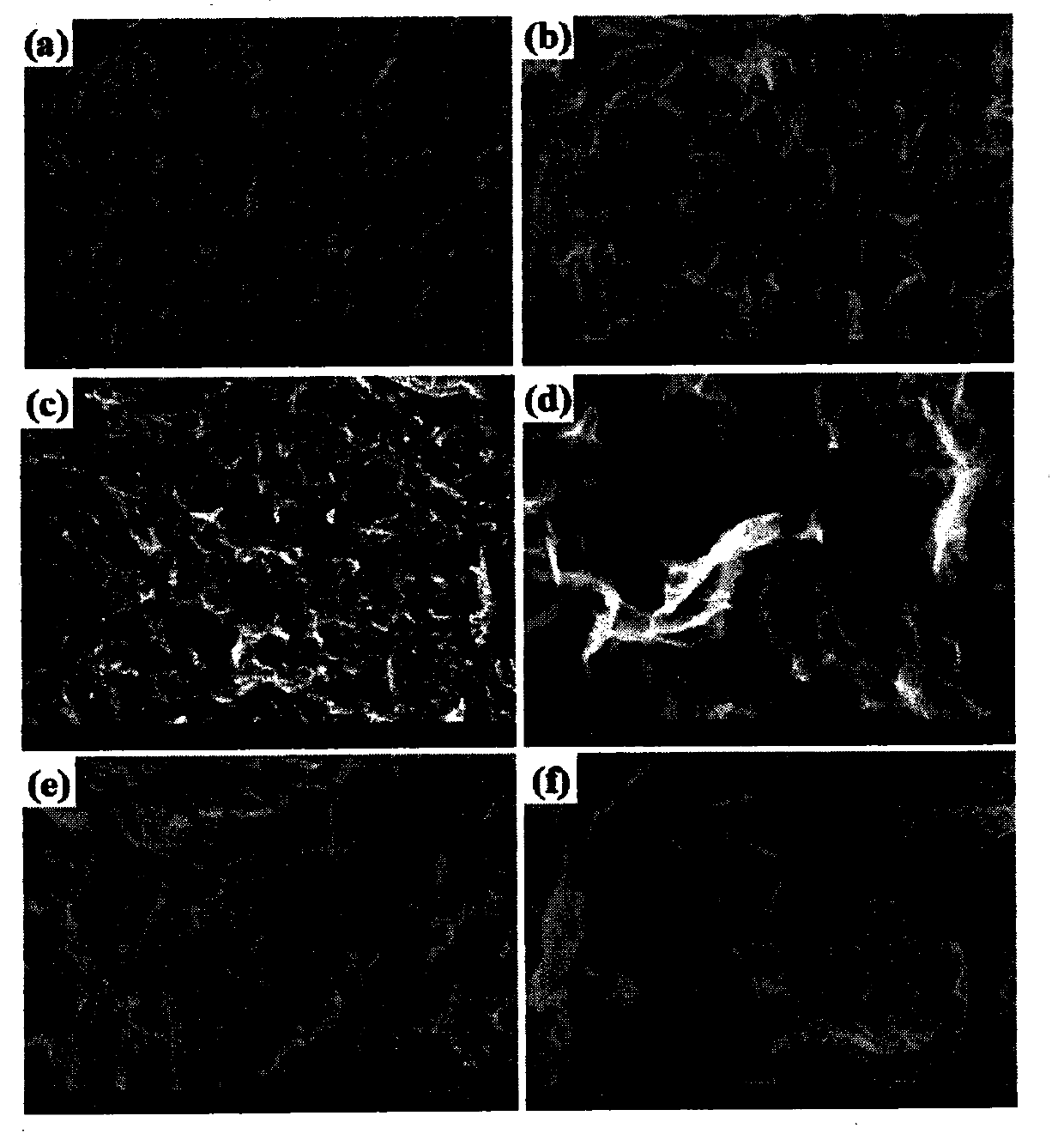

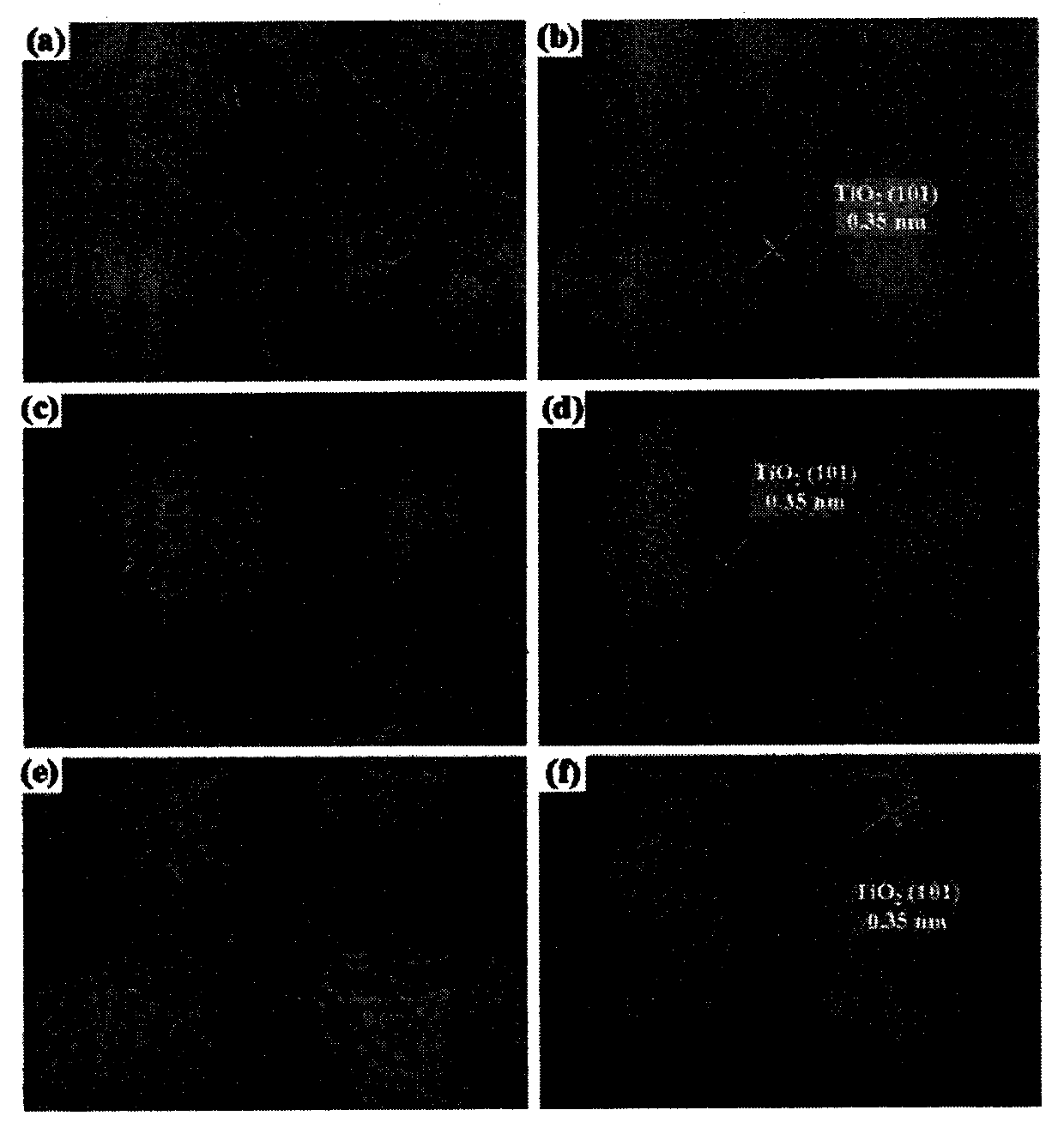

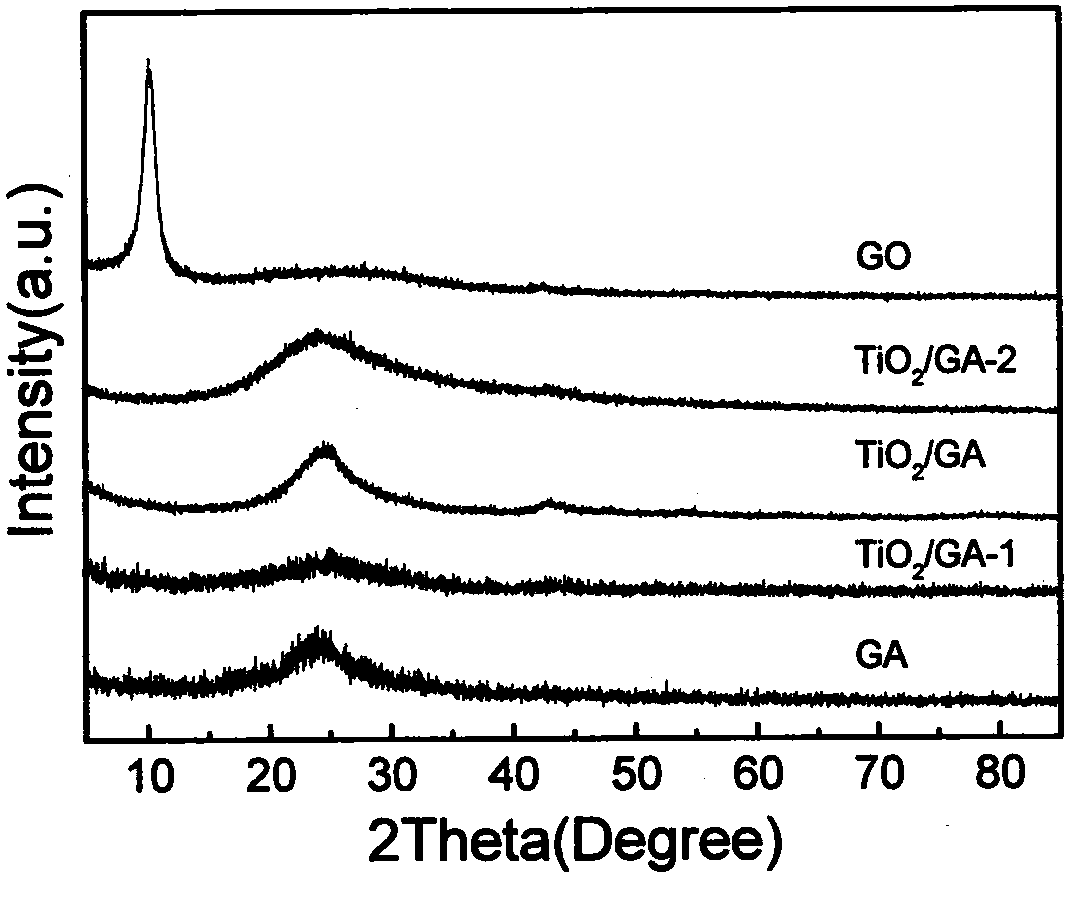

[0032] A graphene-titanium dioxide airgel composite material is obtained by growing nano-titanium dioxide particles on a graphene oxide sheet structure by in-situ polymerization.

[0033] The preparation method of above-mentioned graphene-titanium dioxide airgel composite material, concrete steps are:

[0034] Step 1: Weigh 10g of graphene oxide aqueous dispersion (Carbon Valley Shangxi, GO-1, 10mg / g) into a beaker, and measure 40mL of deionized water in the beaker to make a 2mg / mL graphene oxide solution ;

[0035] Step 2: Measure butyl titanate and add it to absolute ethanol to prepare a butyl titanate-ethanol solution with a concentration of 0.010mol / L;

[0036] Step 3: Measure 1mL of butyl titanate-ethanol solution and slowly add it to 20mL of graphene oxide solution, fully stir the obtained mixed solution on a magnetic stirrer for 3h, put it into a hydrothermal reactor for in-situ polymerization reaction, and react The temperature is 180°C, and the reaction time is 12 h...

Embodiment 2

[0039] Add 20 mg of glucose to the graphene oxide solution in Step 1 in Example 1, and the rest are the same as in Example 1. The composite material finally obtained is denoted as TiO 2 -GA-1.

Embodiment 3

[0041] Change the concentration of the butyl titanate-ethanol solution in Example 1 to 0.05mol / L, all the other are the same as Example 1, and the composite material finally obtained is denoted as TiO2 -GA-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com