Aluminum alloy shell, machining method thereof and electronic equipment

A technology of aluminum alloy casing and processing method, which is applied in the direction of electrolytic coating, telephone structure, surface reaction electrolytic coating, etc., can solve the problems of poor appearance integrity and achieve the effects of improving reliability, good appearance integrity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] figure 2 A schematic flow chart of the scheme of the aluminum alloy shell processing method in Example 1 is shown.

[0040] The aluminum alloy shell processing method of embodiment 1 comprises:

[0041] In step S100 , the aluminum alloy material is processed to obtain the outer shell and the inner cavity structure. The shape and related internal cavity structure processing of aluminum alloy materials can be processed in sequence, such as CNC processing, surface grinding, and surface sandblasting. The non-high-gloss area has completed the processing that should be completed before anodizing.

[0042] Sand blasting is the process of cleaning the surface of the substrate by the impact of high-speed sand flow. Compressed air is used as the power to form a high-speed jet beam to spray the spray material (such as alumina, diamond, corundum, quartz sand, etc.) to the surface of the workpiece to be treated at a high speed, so that the appearance or shape of the outer surface...

Embodiment 2

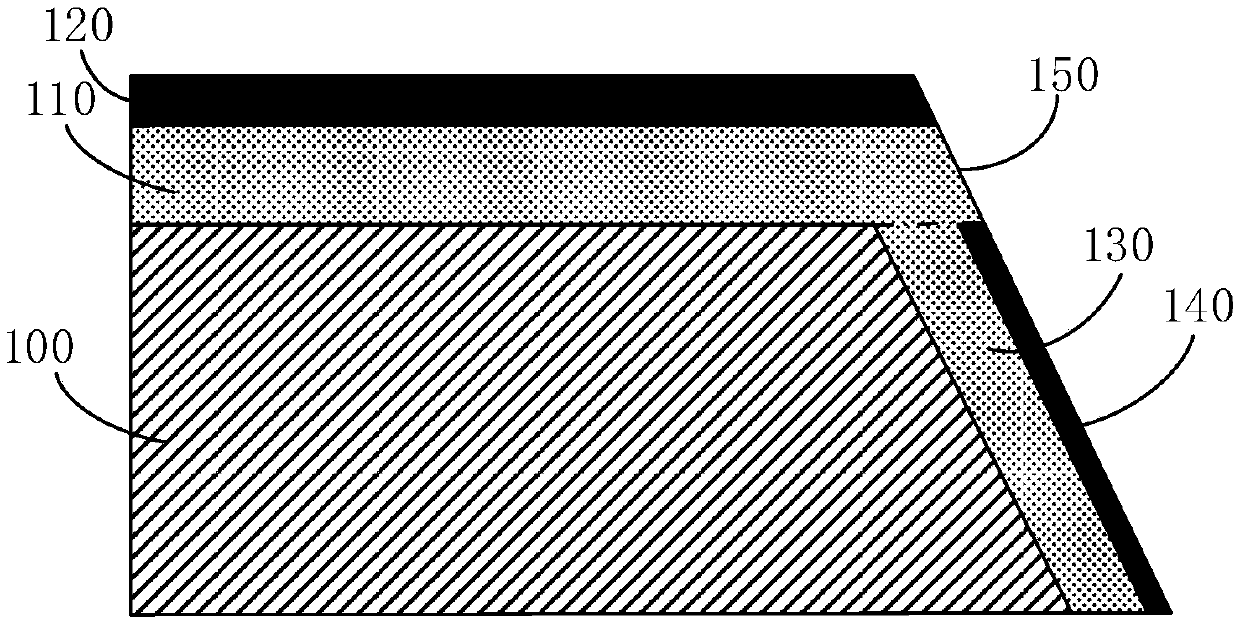

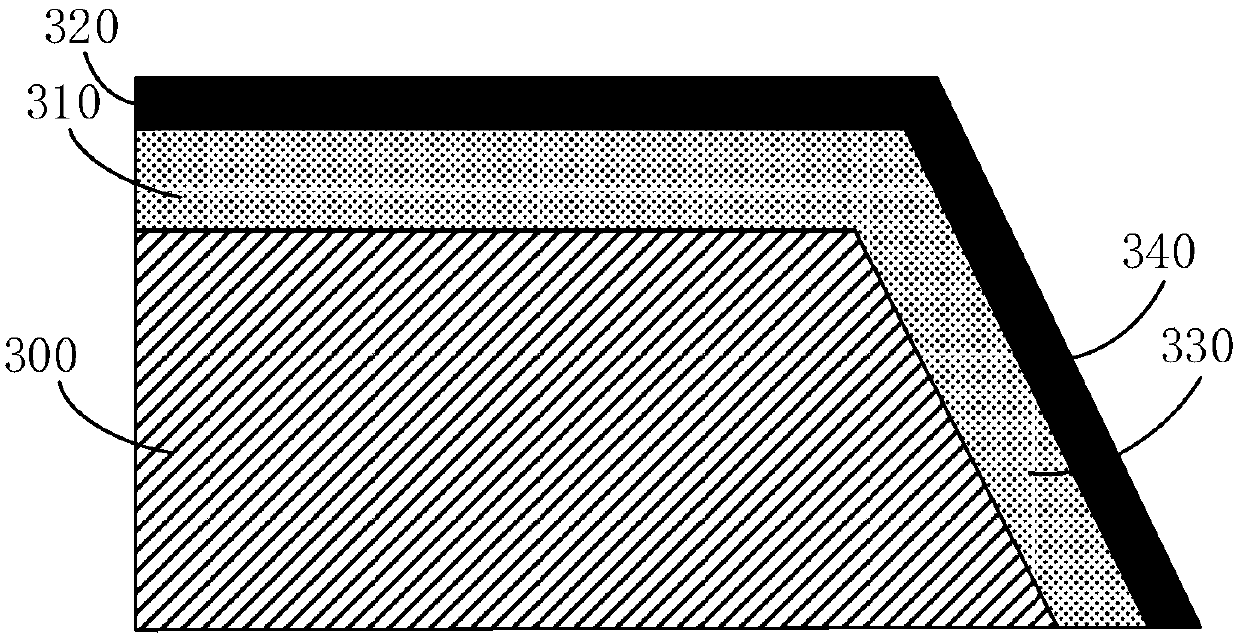

[0064] image 3 A schematic structural view of an aluminum alloy housing according to an embodiment of the present invention is shown. The aluminum alloy shell of the embodiment 2 uses the above-mentioned processing method to obtain an oxide film on the high-gloss side and an oxide film on the non-gloss area through one anodic oxidation process on the aluminum alloy substrate 300 .

[0065] Due to the oxide film on the high-gloss side (including image 3 The second undyed layer 330 and the second dyed layer 340) and the oxide film in the non-high light area (including image 3 The first undyed layer 310 and the first dyed layer 320) are obtained by anodizing at the same time, so they have the same oxide film thickness, color and film properties, and there is no white line that ordinary high-gloss same-color anodizing has, Therefore, the appearance integrity of the highlight edge and the non-highlight area is very good.

[0066] Moreover, the present invention does not need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com