Preparation method of ordered mesopore cathode composite of MEC

A cathode composite material and mesoporous technology, applied in chemical instruments and methods, electrodes, electrode shapes/types, etc., can solve the problems of expensive cathode catalysts, environmental pollution, etc., and achieve faster electron transfer, reduced dependence, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] ⑵ Preparation of nickel cobalt oxide / SBA-15

[0039] Using mesoporous molecular sieve SBA-15 as a hard template, the nickel-cobalt precursor is introduced into the pores of the hard template SBA-15 by impregnation, dried overnight, and then calcined to obtain a catalyst;

[0040] (3) Removal of silicon template

[0041] The catalyst prepared above is placed in NaOH solution or HF solution and stirred to remove the hard template SBA-15 to obtain the catalyst nickel cobalt oxide;

[0042] ⑷ Electrode preparation

[0043] The catalyst nickel cobalt oxide was placed in absolute ethanol, ultrasonicated, and then fixed on both sides of the carbon paper with a binder, and dried at room temperature to prepare the MEC cathode electrode.

[0044] Preferably, the molar percentage of the template agent P123 in the silicon source in step (1) is 0.01-0.03, 0.01, 0.02, 0.03 are optional; the HCl solution is controlled at 1.5-2.5, 1.5, 2.0, 2.5 are optional; the heating and stirring ...

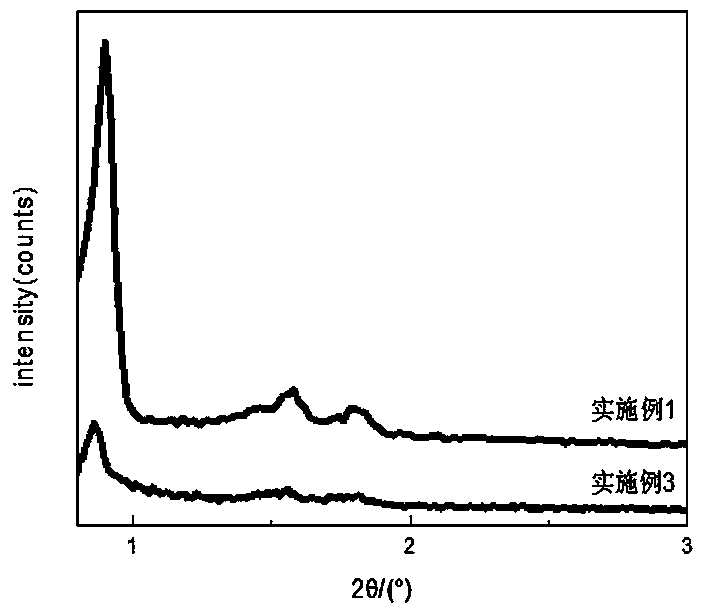

Embodiment 1

[0060] At a water bath temperature of 39°C, 5g of P123 (0.02 mole percent of tetraethyl orthosilicate) was dissolved in 200mL of hydrochloric acid solution at pH=2.0, and after 4 hours, 11mL of tetraethyl orthosilicate was added dropwise and stirred for 20h. Filter, transfer to a reaction kettle, stand at 100°C for 48 hours, filter with suction, dry at 60°C, and bake at 550°C for 5 hours to obtain a white mesoporous hard template SBA-15.

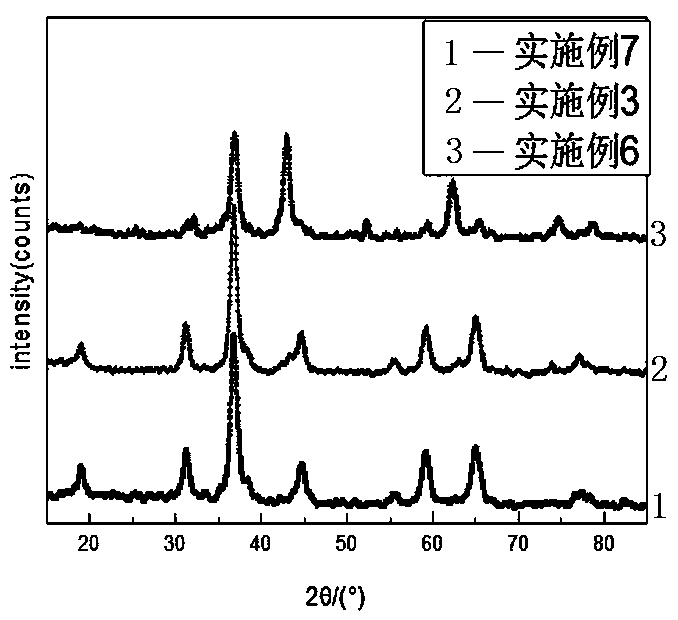

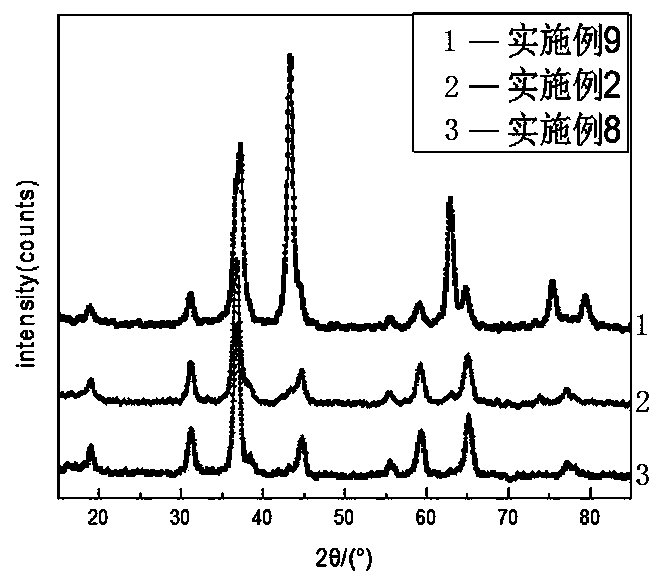

Embodiment 2

[0062] Take a certain amount of nickel-cobalt nitrate (nickel-cobalt mol ratio is 1:2) and be dissolved in dehydrated ethanol solution, add the dried SBA-15 1g of embodiment 1, make it just meet equal-volume impregnation condition (solid-liquid The volume ratio is 1:1), evaporated to dryness under stirring. The obtained samples were dried overnight in an oven at 60 °C, and then calcined at 550 °C for 5 h in a tube furnace under a nitrogen atmosphere. Then, place in 2mol / L NaOH solution at 50°C and stir for 24h to remove the template, then filter and wash with absolute ethanol and distilled water until neutral. Finally, it is dried in an oven at 60°C to obtain the catalyst nickel-cobalt oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com