Epoxy non-cured rubber asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating and non-curing rubber technology, applied in the coating field, can solve the problems of heating construction, harmful gas pollution, etc., and achieve the effects of simplified construction operation, good anti-water channeling performance and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

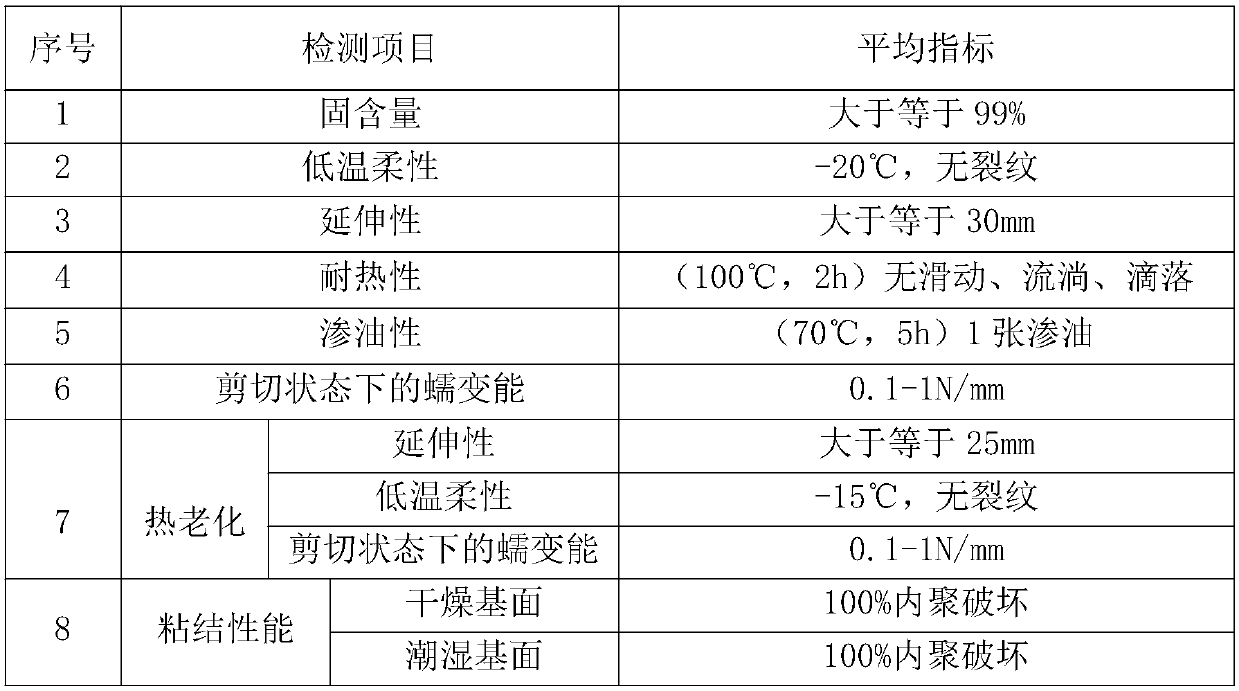

Examples

Embodiment 1

[0043] An epoxy non-curing rubber asphalt waterproof coating, comprising component A and component B, component A and component B are mixed by the mass ratio of A:B=1~90:1;

[0044] The composition of component A is calculated in parts by mass:

[0045] 25 parts of 90# asphalt

[0046] base oil 5 parts

[0047] 1 part rubber SBS

[0048] Epoxy resin E-51 2 parts

[0049] The composition of component B is calculated in parts by mass as follows:

[0050] Polyamide curing agent 2 parts

[0051] An epoxy non-curing rubber asphalt waterproof coating. The preparation method is: add 25 parts of 90# asphalt and 5 parts of base oil into the stirring tank, heat to 180 ° C, stir at high speed, add 1 part of rubber SBS, continue stirring, and react for 0.5 hour, lower the temperature to 140°C, add 2 parts of epoxy resin E-51, continue to stir evenly, cool down to 80°C, and discharge to obtain Component A; Component B is 2 parts of polyamide curing agent; Component A and component B ...

Embodiment 2

[0053] An epoxy non-curing rubber asphalt waterproof coating, comprising component A and component B, component A and component B are mixed by the mass ratio of A:B=1~90:1;

[0054] The composition of component A is calculated in parts by mass:

[0055] 90# asphalt 35 parts

[0056] Minus 20 parts of third-line oil

[0057] Rubber SIS 8 parts

[0058] Epoxy resin NC-513 16 parts

[0059] Dodecyl-tetradecyl glycidyl ether 3.5 parts

[0060] 10 parts of waste car tire rubber powder

[0061] Talcum powder 15 parts

[0062] 2.5 parts of defoamer

[0063] The composition of component B is calculated in parts by mass as follows:

[0064] Polyetheramine curing agent 16 parts

[0065] 1.5 parts of curing accelerator

[0066] An epoxy non-curing rubber asphalt waterproof coating. The preparation method is: add 35 parts of 90# asphalt and 20 parts of third-line oil into the stirring tank, heat to 190 ° C, stir at high speed, add 8 parts of rubber SIS, continue stirring, and rea...

Embodiment 3

[0068]An epoxy non-curing rubber asphalt waterproof coating, comprising component A and component B, component A and component B are mixed by the mass ratio of A:B=1~90:1;

[0069] The composition of component A is calculated in parts by mass:

[0070] 50 parts of 100# asphalt

[0071] Aromatic oil 30 parts

[0072] Rubber SBR 15 parts

[0073] Epoxy resin NC-514 30 parts

[0074] Propyl glycidyl ether 7 parts

[0075] Waste car tire rubber powder 20 parts

[0076] Heavy calcium 30 parts

[0077] 5 parts of coupling agent

[0078] The composition of component B is calculated in parts by mass as follows:

[0079] Cardanol curing agent 30 parts

[0080] 3 parts curing accelerator

[0081] An epoxy non-curing rubber asphalt waterproof coating, its preparation method is: add 50 parts of 100# asphalt and 30 parts of aromatic oil into the stirring tank, heat it to 200 ° C, stir at high speed, add 15 parts of rubber SBR, continue stirring, and react 2 hour, add 20 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com