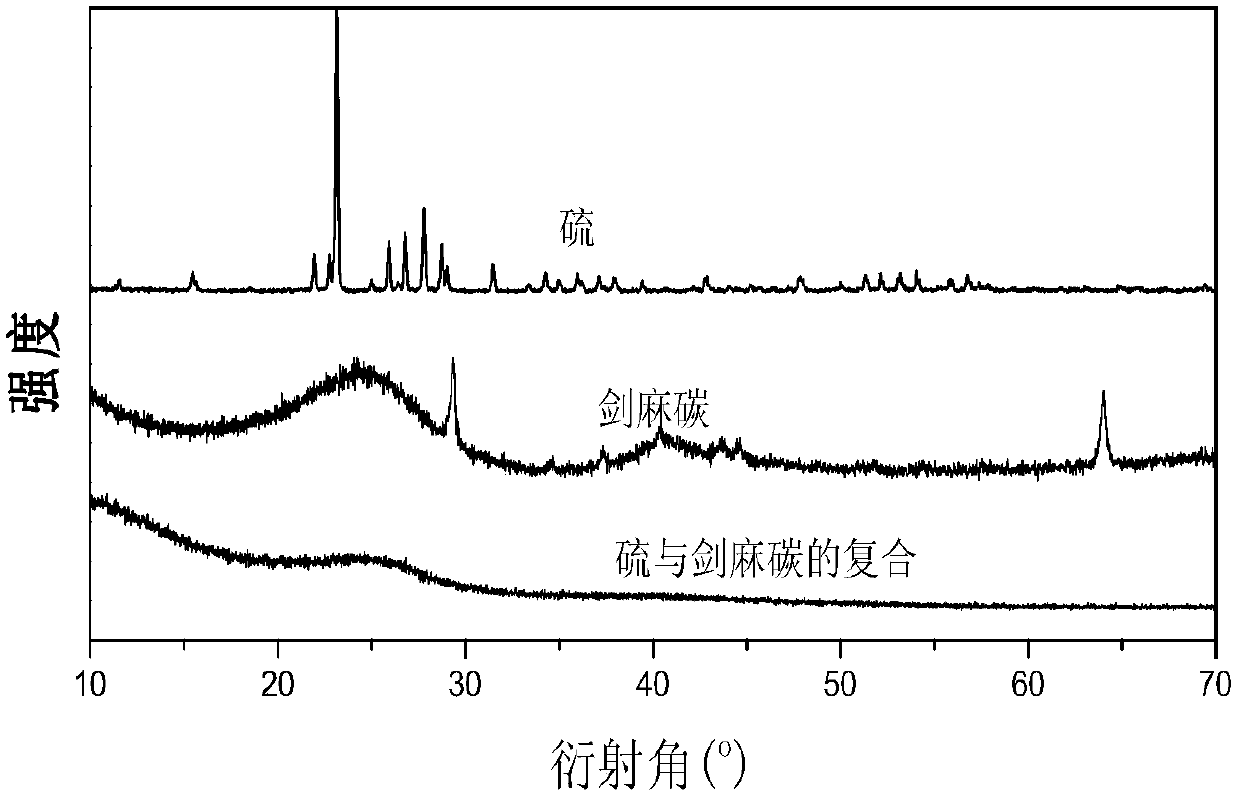

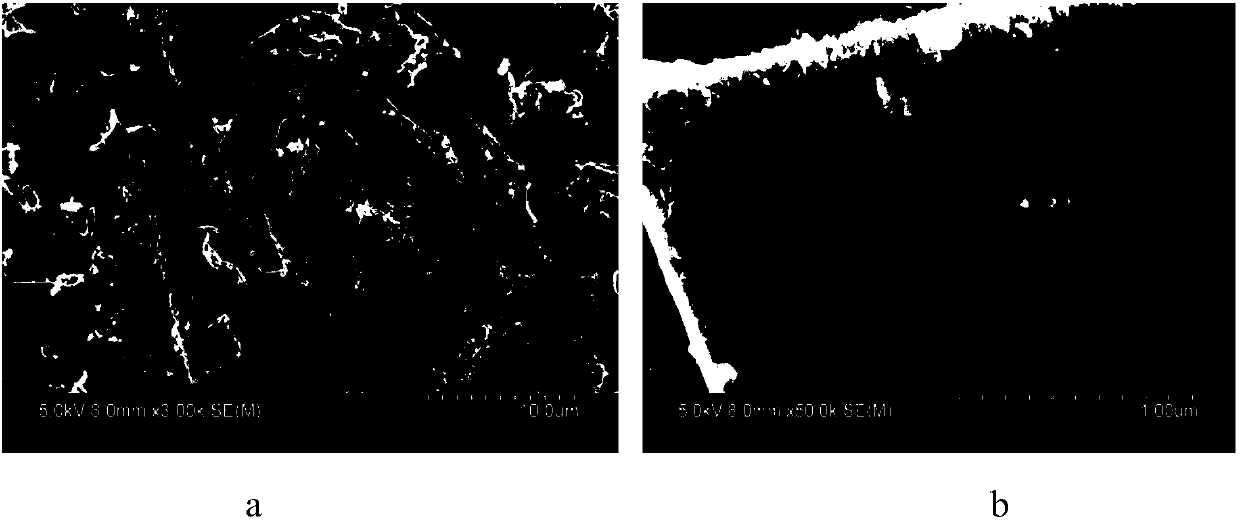

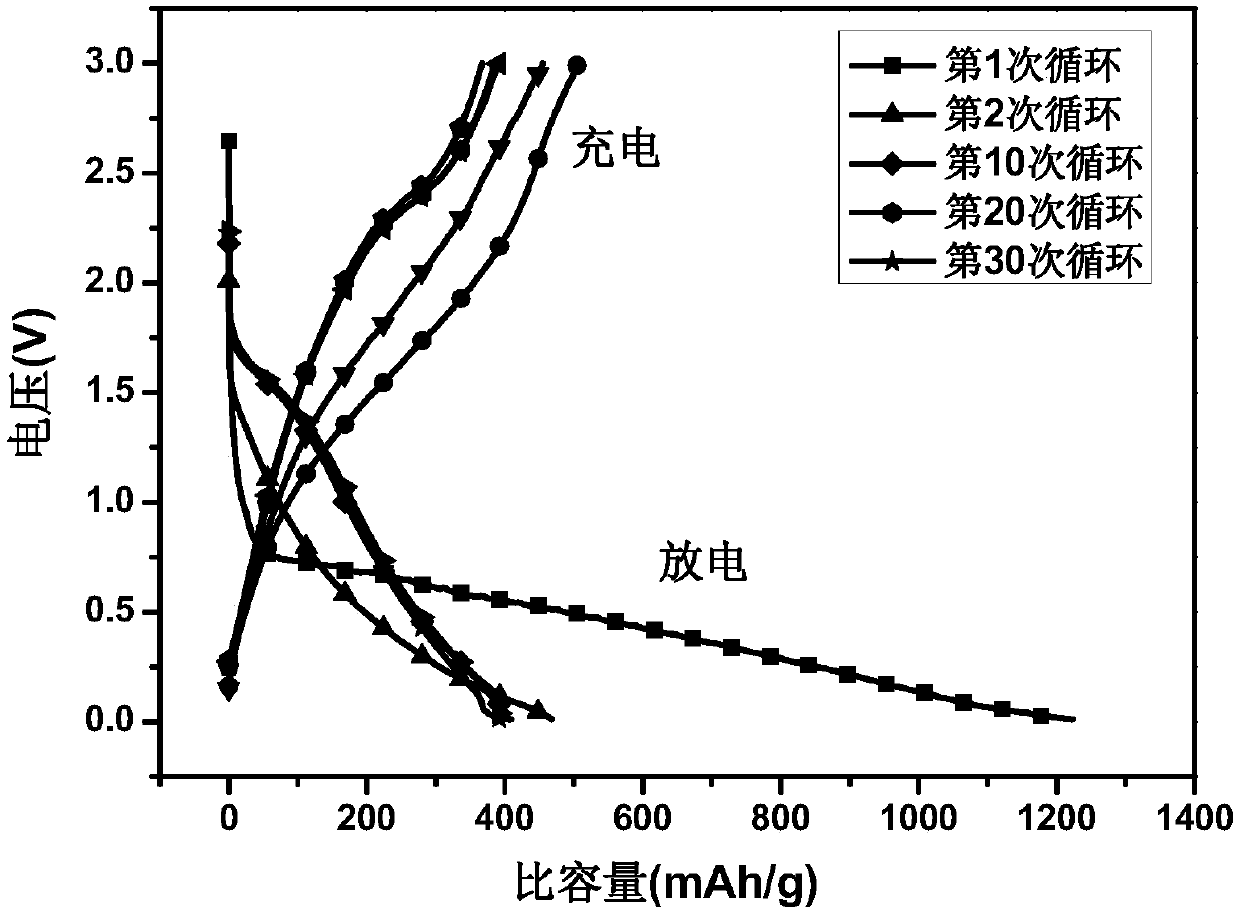

Preparation method of sulfur/sisal fiber charcoal lithium ion battery composite negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity, poor electrochemical properties of materials, and unfavorable electron transport, achieving high specific capacity, excellent electrochemical performance, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Sulfuric acid and sodium thiosulfate pentahydrate were configured into sulfuric acid solution and sodium thiosulfate solution with a concentration of 2 mol / L respectively with deionized water.

[0021] (2) The cleaned sisal fiber is cut into 2-3 centimeter segments, weighs 5 g and puts it into the polytetrafluoroethylene lining of the autoclave, and takes 35 mL of the two solutions of step (1) with a graduated cylinder Pour it into the lining of the above reaction kettle in turn, then ultrasonically oscillate for 30 minutes, then place the lining in the reaction kettle, cover the reaction kettle tightly, and conduct a hydrothermal reaction in a closed reaction kettle for 12 hours at a reaction temperature of 120°C. After the reaction is completed Wash the black product with water until neutral, and dry it in a vacuum oven at 50°C.

[0022] (3) The black product dried in step (2) was calcined for 0.5 hour under a nitrogen atmosphere with a gas flow rate of 50ml / min, ...

Embodiment 2

[0027] (1) Sulfuric acid and sodium thiosulfate pentahydrate were configured into sulfuric acid solution and sodium thiosulfate solution with a concentration of 2 mol / L respectively with deionized water.

[0028] (2) The cleaned sisal fiber is cut into 2-3 centimeter segments, weighs 5 g and puts it into the polytetrafluoroethylene lining of the autoclave, and takes 35 mL of the two solutions of step (1) with a graduated cylinder Pour it into the lining of the above reaction kettle in turn, then ultrasonically oscillate for 30 minutes, then place the lining in the reaction kettle, cover the reaction kettle tightly, and conduct a hydrothermal reaction in a closed reaction kettle for 12 hours at a reaction temperature of 140°C. After the reaction is completed Wash the black product with water until neutral, and dry it in a vacuum oven at 50°C.

[0029] (3) The black product dried in step (2) was calcined for 0.5 hour under a nitrogen atmosphere with a gas flow rate of 50ml / min, ...

Embodiment 3

[0032] (1) Sulfuric acid and sodium thiosulfate pentahydrate were configured into sulfuric acid solution and sodium thiosulfate solution with a concentration of 2 mol / L respectively with deionized water.

[0033] (2) The cleaned sisal fiber is cut into 2-3 centimeter segments, weighs 5 g and puts it into the polytetrafluoroethylene lining of the autoclave, and takes 35 mL of the two solutions of step (1) with a graduated cylinder Pour it into the lining of the above reaction kettle in turn, then ultrasonically vibrate for 30 minutes, then put the lining in the reaction kettle, cover the reaction kettle tightly, and react hydrothermally in the closed reaction kettle for 12 hours, the reaction temperature is 160°C, after the reaction is completed Wash the black product with water until neutral, and dry it in a vacuum oven at 50°C.

[0034] (3) The black product dried in step (2) was calcined for 0.5 hour under a nitrogen atmosphere with a gas flow rate of 50ml / min, the calcining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com