Preparation method of a fully spin-coated flexible composite piezoelectric generator

A flexible piezoelectric and generator technology, applied in the manufacture/assembly of magnetostrictive devices, etc., can solve the problems of film piezoelectric performance degradation and easy breakdown, so as to increase the content of piezoelectric phase and improve biocompatibility Sexuality, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

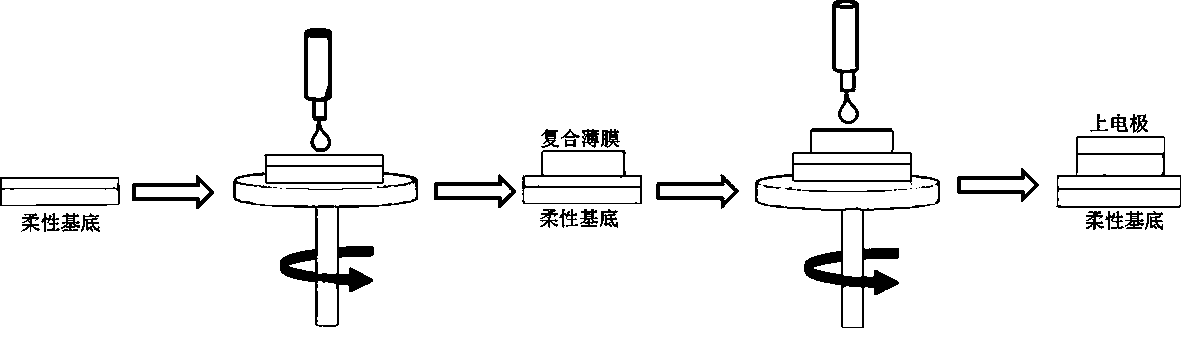

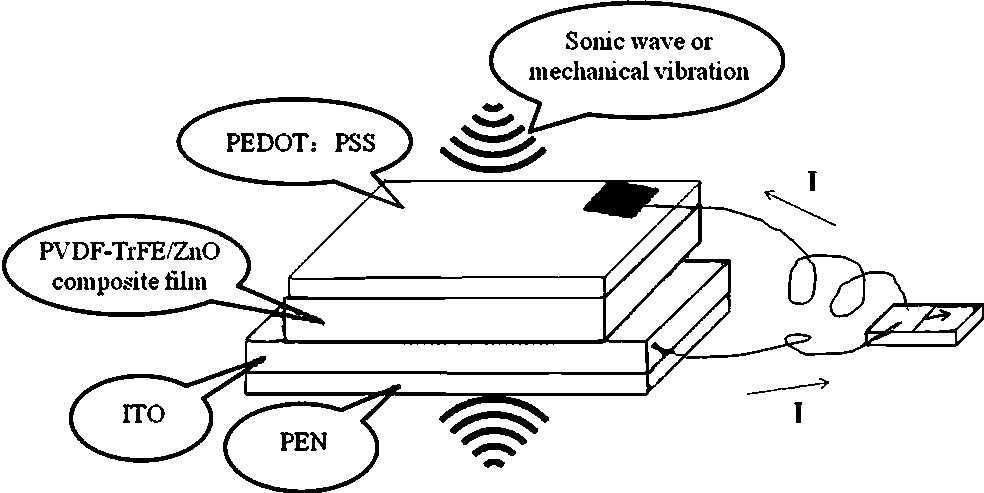

[0092] (1) Preparation of PVDF-TrFE / nano-ZnO composite film

[0093] Dissolve 1.500g PVDF-TrFE solid in 5ml N,N-dimethylformamide, and mix mechanically for 60min at room temperature to obtain a transparent viscous clear solution; dissolve 0.075g nanometer zinc oxide in 5ml acetone, add 0.2ml n-Propylamine and 0.0003g 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane, at room temperature, ultrasonically stirred and mixed for 30 minutes to obtain a transparent and clear solution; inject the nano-ZnO dispersion into the PVDF-TrFE solution, and mix mechanically for 60 minutes , to obtain a translucent homogeneous solution. The above mixed solution was placed in a vacuum drying oven, and stood at room temperature in a vacuum of 0.09 MPa for 30 minutes to remove air bubbles in the solution. Use a syringe to draw 0.3ml of the mixed solution, drop it into the center of the cleaned ITO-PEN conductive glass with a size of 2cm×2cm, turn on the pump to fix the substrate, the speed of the firs...

Embodiment 2

[0097] (1) Preparation of PVDF-TrFE / nano-ZnO composite film

[0098] Dissolve 1.500g PVDF-TrFE solid in 5ml N,N-dimethylformamide, and mix mechanically for 60min at room temperature to obtain a transparent viscous clear solution; dissolve 0.075g nanometer zinc oxide in 5ml acetone, add 0.2ml n-Propylamine and 0.0003g 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane, at room temperature, ultrasonically stirred and mixed for 30 minutes to obtain a transparent and clear solution; inject the nano-ZnO dispersion into the PVDF-TrFE solution, and mix mechanically for 60 minutes , to obtain a translucent homogeneous solution. The above mixed solution was placed in a vacuum drying oven, and stood at room temperature in a vacuum of 0.09 MPa for 30 minutes to remove air bubbles in the solution. Use a syringe to draw 0.3ml of the mixed solution, drop it into the center of the cleaned ITO-PEN conductive glass with a size of 2cm×2cm, turn on the pump to fix the substrate, the speed of the firs...

Embodiment 3

[0102] (1) Preparation of PVDF-TrFE / nano-ZnO composite film

[0103] Dissolve 1.500g PVDF-TrFE solid in 5ml N,N-dimethylformamide, and mix mechanically for 60min at room temperature to obtain a transparent viscous clear solution; dissolve 0.075g nanometer zinc oxide in 5ml acetone, add 0.2ml n-Propylamine and 0.0003g 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane, at room temperature, ultrasonically stirred and mixed for 30 minutes to obtain a transparent and clear solution; inject the nano-ZnO dispersion into the PVDF-TrFE solution, and mix mechanically for 60 minutes , to obtain a translucent homogeneous solution. The above mixed solution was placed in a vacuum drying oven, and stood at room temperature in a vacuum of 0.09 MPa for 30 minutes to remove air bubbles in the solution. Use a syringe to draw 0.3ml of the mixed solution, drop it into the center of the cleaned ITO-PEN conductive glass with a size of 2cm×2cm, turn on the pump to fix the substrate, the speed of the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com