Preparation method of AlGaInP thin film LED chip dicing line

A technology of LED chips and dicing lanes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of highly toxic elemental bromine, hidden dangers to the health of craftsmen and environmental safety, and difficulty in controlling the stability and consistency of corrosive liquids and other issues, to achieve good stability and consistency, and to protect the health of the body and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing AlGaInP thin film LED chip dicing lines, comprising the following steps:

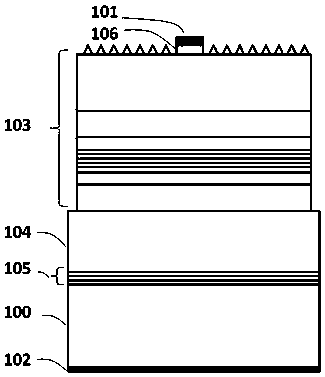

[0029] First, the epitaxial material is prepared by conventional MOCVD, and then the epitaxial material is transferred to the bonded substrate by using metal evaporation, photolithography, corrosion, bonding, and alloying.

[0030] At this time, the AlGaInP thin film LED chips are connected. In order to divide the AlGaInP thin film LED chips, it is necessary to prepare a dicing line, and then perform AlGaInP thin film LED chip point measurement and AlGaInP thin film LED chip cutting. The specific steps are as follows:

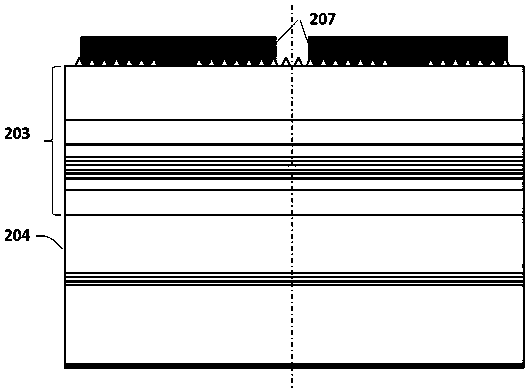

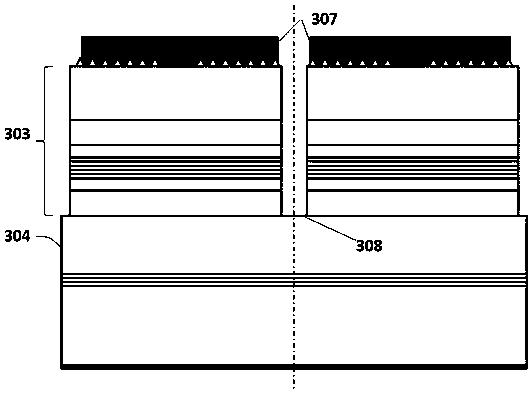

[0031] A. Coat the photoresist on the surface of the AlGaInP thin film LED chip, remove the photoresist in the area corresponding to the cutting line of the AlGaInP thin film LED chip by conventional photolithography process, and expose the AlGaInP LED epitaxial material. At this time, the structure is as follows figure 2 shown;

[0032] B. Preparation of ...

Embodiment 2

[0040] A method for preparing AlGaInP thin film LED chip dicing lines, comprising the following steps:

[0041] First, the epitaxial material is prepared by conventional MOCVD, and then the epitaxial material is transferred to the bonded substrate by using metal evaporation, photolithography, corrosion, bonding, and alloying.

[0042] At this time, the AlGaInP thin film LED chips are connected. In order to divide the AlGaInP thin film LED chips, it is necessary to prepare a dicing line, and then perform AlGaInP thin film LED chip point measurement and AlGaInP thin film LED chip cutting. The specific steps are as follows:

[0043] A. Coat the photoresist on the surface of the AlGaInP thin film LED chip, remove the photoresist in the area corresponding to the cutting line of the AlGaInP thin film LED chip by conventional photolithography process, and expose the AlGaInP LED epitaxial material. At this time, the structure is as follows figure 2 shown;

[0044] B. Preparation of ...

Embodiment 3

[0052] A method for preparing AlGaInP thin film LED chip dicing lines, comprising the following steps:

[0053] First, the epitaxial material is prepared by conventional MOCVD, and then the epitaxial material is transferred to the bonded substrate by using metal evaporation, photolithography, corrosion, bonding, and alloying.

[0054] At this time, the AlGaInP thin film LED chips are connected. In order to divide the AlGaInP thin film LED chips, it is necessary to prepare a dicing line, and then perform AlGaInP thin film LED chip point measurement and AlGaInP thin film LED chip cutting. The specific steps are as follows:

[0055] A. Coat the photoresist on the surface of the AlGaInP thin film LED chip, remove the photoresist in the area corresponding to the cutting line of the AlGaInP thin film LED chip by conventional photolithography process, and expose the AlGaInP LED epitaxial material. At this time, the structure is as follows figure 2 shown;

[0056] B. Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com