Laser cladding process

A laser cladding and process technology, applied in the direction of metal material coating process, coating, etc., can solve the problems that affect the performance of parts, long research and development cycle, and few solutions, so as to reduce the degree of defects, less cracks, and reduce internal The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

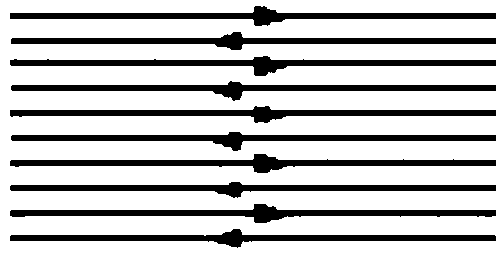

[0038] Such as Figure 1-Figure 6 As shown, a laser cladding process has the following steps:

[0039] S1. Put the YCF101 powder in a drying oven and dry it at a constant temperature of 80°C for 5 hours. After that, pour it into the laser cladding powder feeder, and use coaxial powder feeding for cladding;

[0040] S2. Grinding the substrate and cleaning it with alcohol to remove impurities to obtain a smooth substrate to be clad;

[0041] S3. Use the IPG fiber laser to perform layer-by-layer laser cladding on the clean substrate to be clad according to certain laser processing parameters and certain laser scanning strategies;

[0042] The laser processing parameters are: scanning power 450W, scanning speed 6mm / s, powder feeding rate 12.16g / min, protective gas flow rate 15L / h, powder feeding gas flow rate 6L / h, distance between the nozzle and the substrate to be clad is 14~ 16mm, the shielding gas and the powder feeding gas are both helium, the laser scanning strategy is: tw...

Embodiment 2

[0047] Such as Figure 7-Figure 13 As shown, a laser cladding process has the following steps:

[0048] S1. Put the YCF101 powder in a drying oven and dry it at a constant temperature of 80°C for 5 hours. After that, pour it into the laser cladding powder feeder, and use coaxial powder feeding for cladding;

[0049]S2. Grinding the substrate and cleaning it with alcohol to remove impurities to obtain a smooth substrate to be clad;

[0050] S3. Use the IPG fiber laser to perform layer-by-layer laser cladding on the clean substrate to be clad according to certain laser processing parameters and certain laser scanning strategies;

[0051] The laser processing parameters are: scanning power 450W, scanning speed 6mm / s, powder feeding rate 12.16g / min, shielding gas flow rate 15L / h, powder feeding gas flow rate 6L / h, distance between the nozzle and the substrate to be clad is 14~ 16mm, the shielding gas and the powder feeding gas are both helium, the laser scanning strategy is: two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com