Pretreatment system for environment-friendly process of secondary utilization of plant branches and leaves

A branch and leaf and environmental protection technology is applied in the pre-treatment system of the environmental protection process for the secondary utilization of plant branches and leaves, and the recycling process of waste plant branches and leaves, which can solve the problems of unfavorable subsequent fermentation and poor pulverization effect, and achieve good pulverization effect and improve pulverization. effect, the effect of improving the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

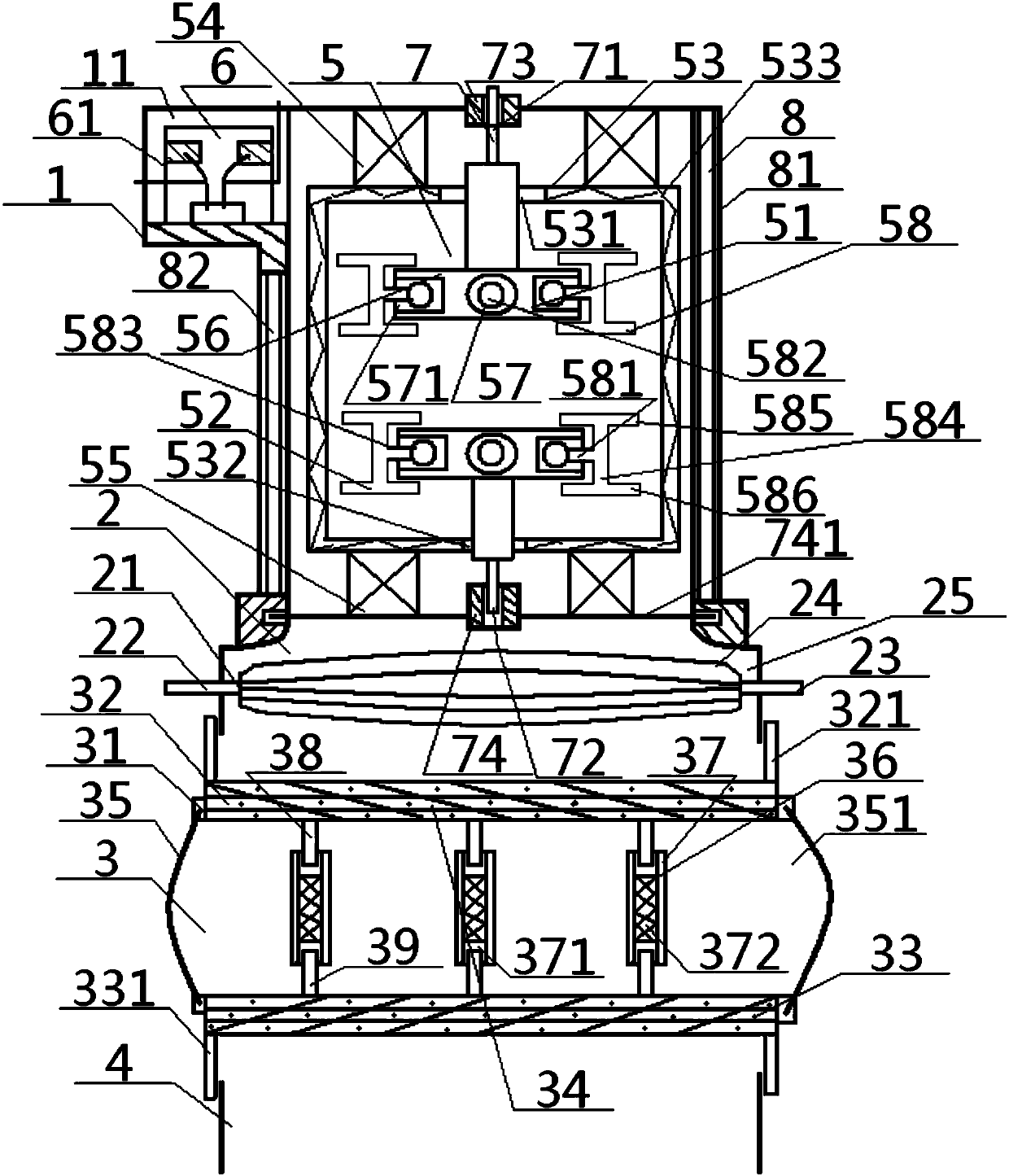

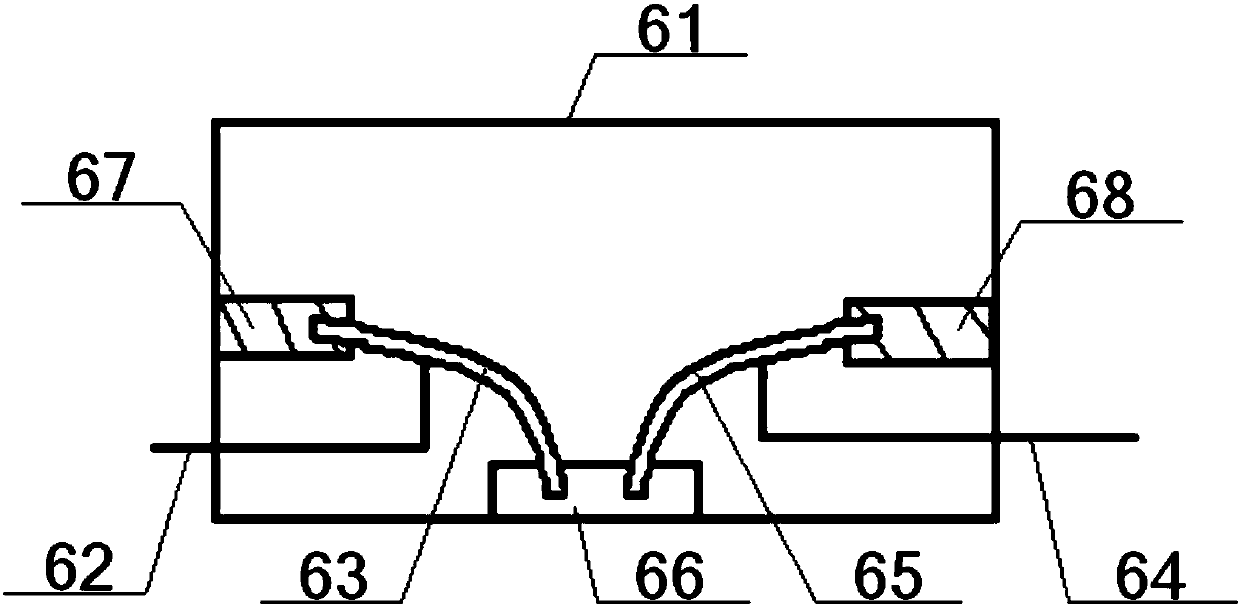

[0027] see Figure 1 to Figure 2 , a pre-treatment system for the environmental protection process of secondary utilization of plant branches and leaves, including a processing machine room 1, a crushing assembly 5, a main crushing shaft 7, a screening pipeline 3 and a discharge pipeline 4, and the inside of the processing machine room 1 is provided with a crushing assembly 5. There is a main crushing shaft 7 passing through the middle of the crushing assembly 5. The top and bottom ends of the main crushing shaft 7 are respectively connected to the middle of the upper drive bearing 73 and the lower fixed bearing 74. The bottom of the processing machine room 1 is screened through the pipeline. 3 is communicated with the discharge pipe 4;

[0028] The outer wall of the upper driving bearing 73 is connected with the top of the processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com