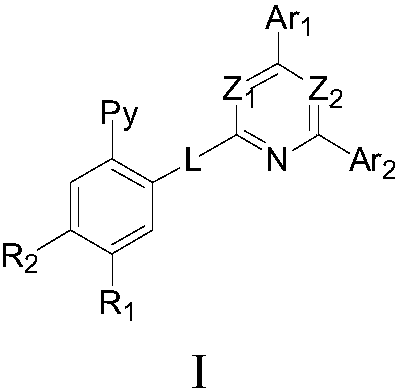

Organic electroluminescent compound based on pyridine and triazine and organic electroluminescent device thereof

A compound and luminescent technology, applied in organic chemistry, electrical solid devices, electrical components, etc., can solve the problems of low electron mobility, affecting device life and efficiency, low electron mobility, etc., and achieve high luminous purity and good heat The effect of stability and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Synthesis of compound 2

[0059]

[0060] In the flask, add intermediate 1-1 (1.8g, 5.7mmol), 2,4-diphenyl-6-[3-(4,4,5,5-tetramethyl-1,3,2- Dioxaborolan-2-yl)phenyl]-1,3,5-triazine (2.5g, 5.7mmol), potassium carbonate (1.6g, 11.5mmol), tetrahydrofuran (20mL), water (10mL ), palladium acetate (0.1g), X-Phos (0.2g), heated to reflux under nitrogen protection for 24 hours, cooled, extracted with dichloromethane, dried, concentrated, and the crude product was purified by column chromatography to obtain 1.8g of the product. rate 55%.

[0061] Prepare the following other compounds with similar synthetic methods, see the following table:

[0062] Table 2

[0063]

[0064]

[0065] Synthesis of Intermediate 2-1

[0066]

[0067] In a flask, add 3-chloro-4-bromo-iodobenzene (5g, 15.9mmol), 1-naphthaleneboronic acid (2.7g, 15.9mmol), potassium carbonate (4.4g, 32mmol), tetrahydrofuran (30mL), water ( 15mL), tetrakistriphenylphosphine palladium (0.3g), heated to r...

Embodiment 9

[0078] Synthesis of compound 27

[0079]

[0080] In a flask, add Intermediate 3-1 (3g, 5.5mmol), 3-pyridineboronic acid pinacol ester (1.3g, 6.6mmol), potassium carbonate (1.5g, 11mmol), dioxane (20mL), Water (10mL), palladium acetate (0.1g), X-Phos (0.2g), under nitrogen protection, heated to reflux for 24 hours, cooled, extracted with dichloromethane, and purified by column chromatography to obtain a yield of 1.6g, product rate 48%.

[0081] Other compounds in Table 5 were prepared by similar synthetic methods:

[0082] table 5

[0083]

[0084]

Embodiment 13-24

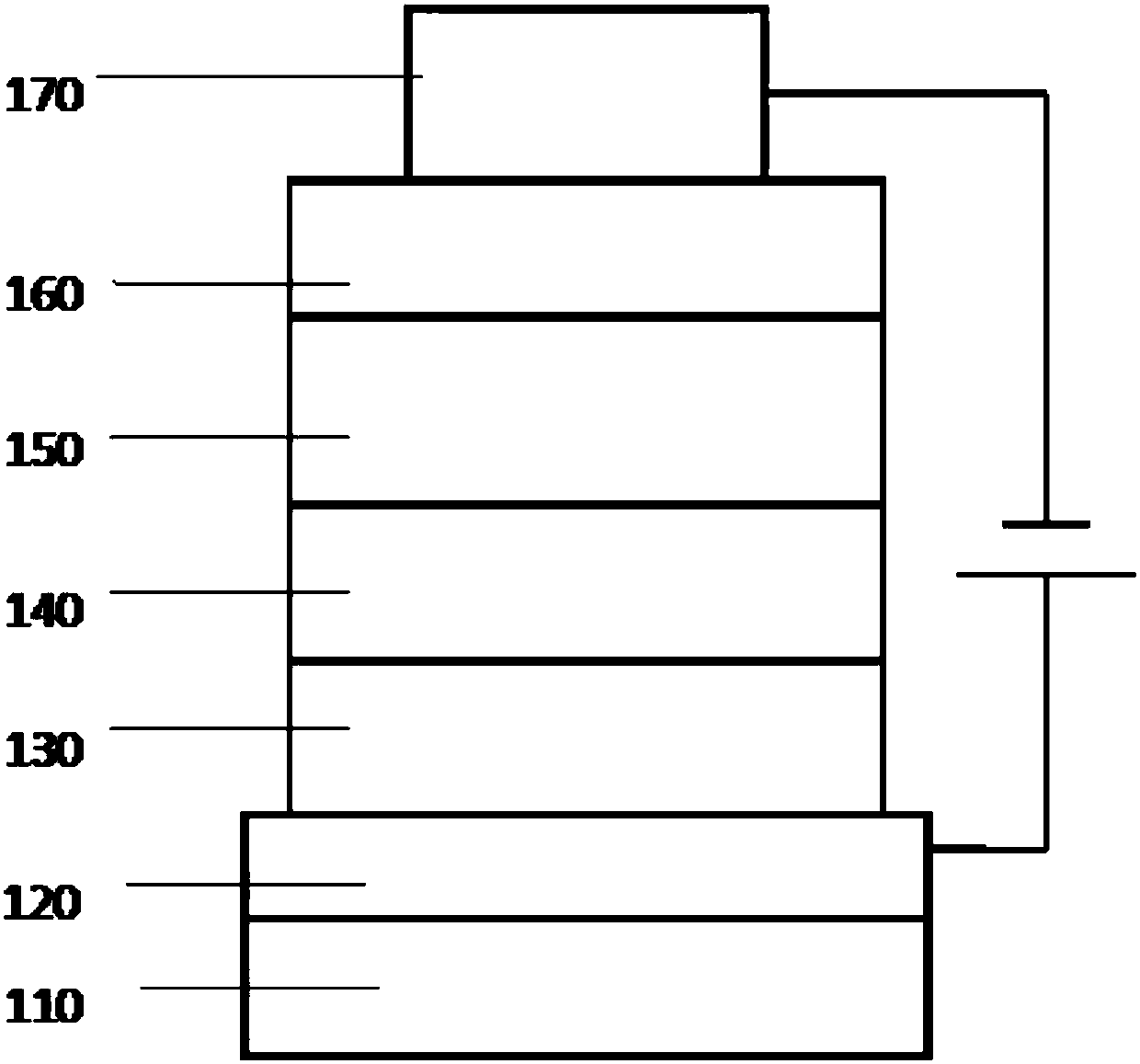

[0086] Fabrication of Organic Electroluminescent Devices

[0087] Preparation of OLEDs using compounds of the invention

[0088] First, the transparent conductive ITO glass substrate 110 (with the anode 120 on it) (China CSG Group Co., Ltd.) is washed with deionized water, ethanol, acetone and deionized water in sequence, and then treated with oxygen plasma for 30 seconds.

[0089] Then, NPB was evaporated to form a hole transport layer 130 with a thickness of 60 nm.

[0090] Then, 37.5nm thick Alq was evaporated on the hole transport layer 3 Doped with 1% C545T as the light emitting layer 140 .

[0091] Then, the compound of the present invention was vapor-deposited as an electron transport layer 150 in a thickness of 37.5 nm on the light emitting layer.

[0092] Finally, 1nm LiF was vapor-deposited as the electron injection layer 160 and 100nm Al as the cathode 170 of the device.

[0093] The prepared device (the schematic diagram of the structure is shown in figure 1 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com