Extraction and purification method for high-purity purple sweet potato anthocyanin

A purple potato anthocyanin and purification method technology, applied in the field of high-purity purple potato anthocyanin extraction and purification, can solve the problem of low upgrading, and achieve the effects of reducing solvent consumption, shortening extraction time, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

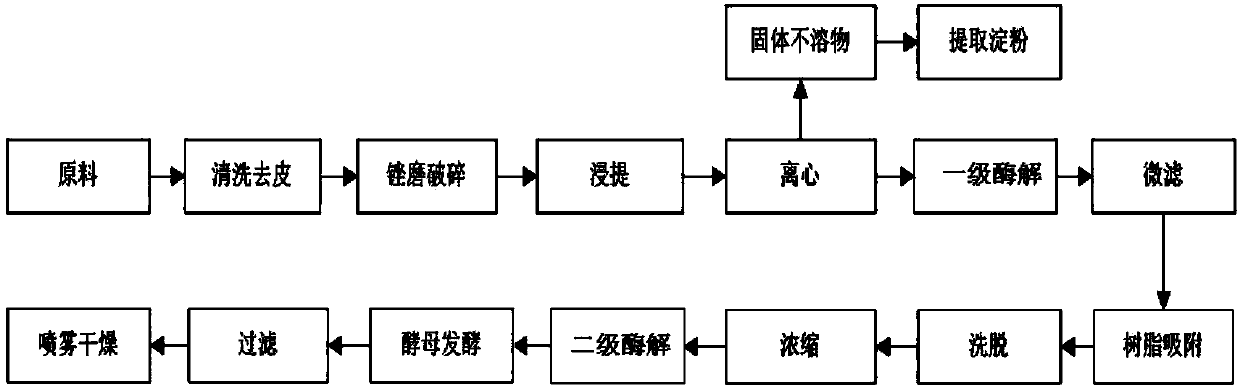

[0053] Such as figure 1Shown, present embodiment adopts 500kg purple potato to extract anthocyanin example, adopts the following steps:

[0054] (1) Cleaning and peeling

[0055] Take 500kg of fresh purple sweet potatoes, wash and remove stones with a paddle cleaner, and then transfer them to a brush cleaning and peeling machine for deep cleaning and peeling.

[0056] (2) Filing and grinding

[0057] After the peeled purple sweet potato is preliminarily crushed by a crusher, it is then crushed by a rasping machine, so that the cells of the purple sweet potato are fully broken.

[0058] (3) Extraction Add acid aqueous solution to the crushed purple sweet potato cells for extraction, adjust the pH of the extraction solution to 2.0, the ratio of solid to liquid is 1:3, and extract for 1 hour to obtain the extraction solution.

[0059] (4) centrifugal

[0060] The extract is centrifuged with a horizontal spiral centrifuge, and solid-liquid separation is performed to obtain an ...

Embodiment 2

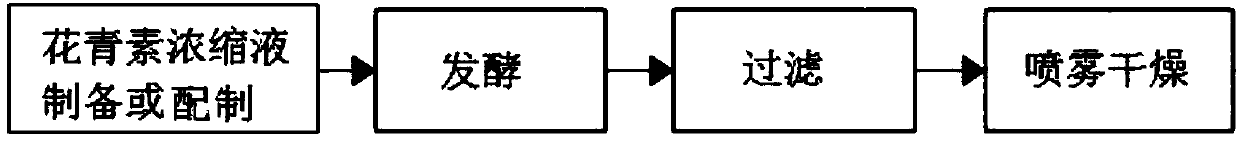

[0080] Such as figure 2 As shown, the present embodiment adopts the commercially available 100g purple sweet potato anthocyanin crude product deep purification example, comprising the following steps:

[0081] (1) Preparation of anthocyanin solution

[0082] Dissolve 100 g of commercially available purple potato anthocyanins in pure water to prepare an anthocyanin solution with a solid content concentration of 20%.

[0083] (2) Yeast activation

[0084] Dried Saccharomyces cerevisiae was added to 5% sugar water at a dosage of 5%, rehydrated at 38°C for 15min, and then rapidly cooled to 30°C for 1h activation.

[0085] (3) fermentation

[0086] Adjust the pH value of the anthocyanin solution to 4.5, control the temperature at 60°C, add glucoamylase for enzymolysis, the amount of glucoamylase added is 15u / ml solution, after 2 hours of enzymolysis, adjust the temperature of the anthocyanin solution to 30°C, add The activated Saccharomyces cerevisiae was subjected to aerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com