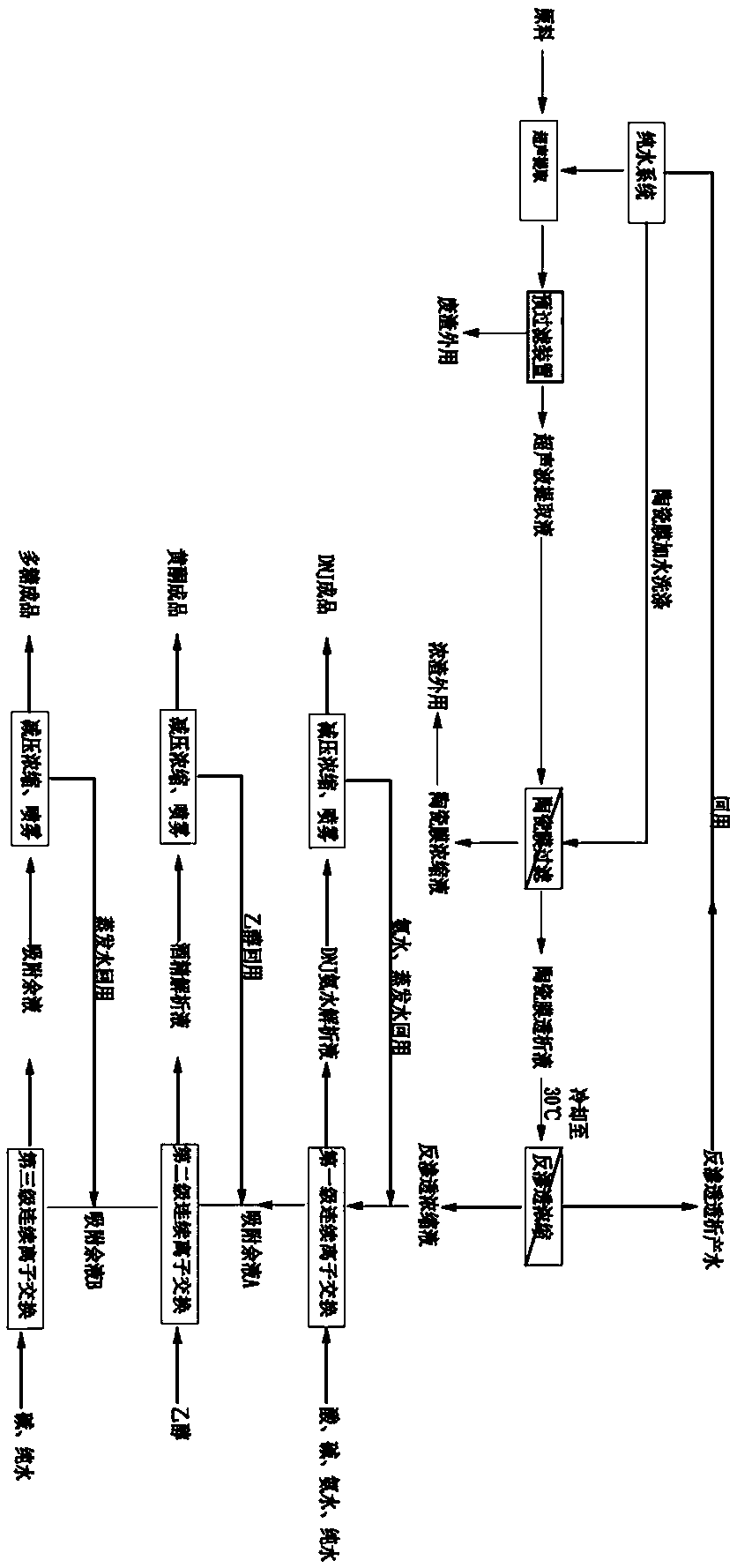

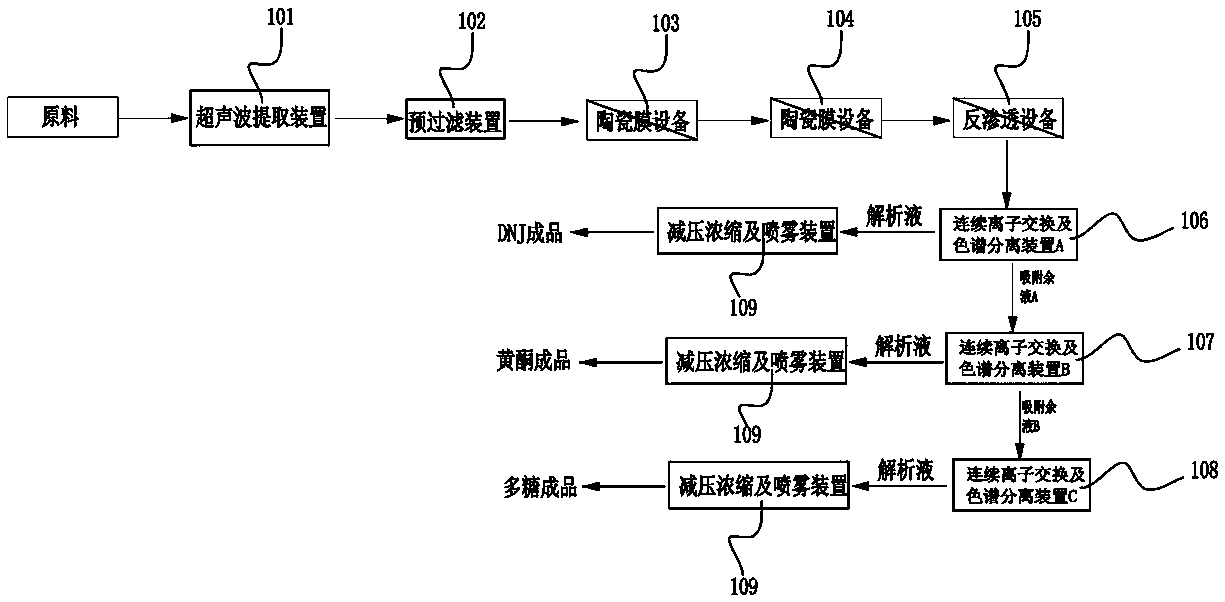

Method and system for continuously extracting DNJ, flavonoids and polysaccharides from moraceae plant

A plant and flavonoid technology, applied in the system of polysaccharides, flavonoids, and DNJ continuously separated and purified, can solve the problems of cumbersome process, long overall process time, complicated operation, etc., achieve simple process and system process, save manpower and material resources, product high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

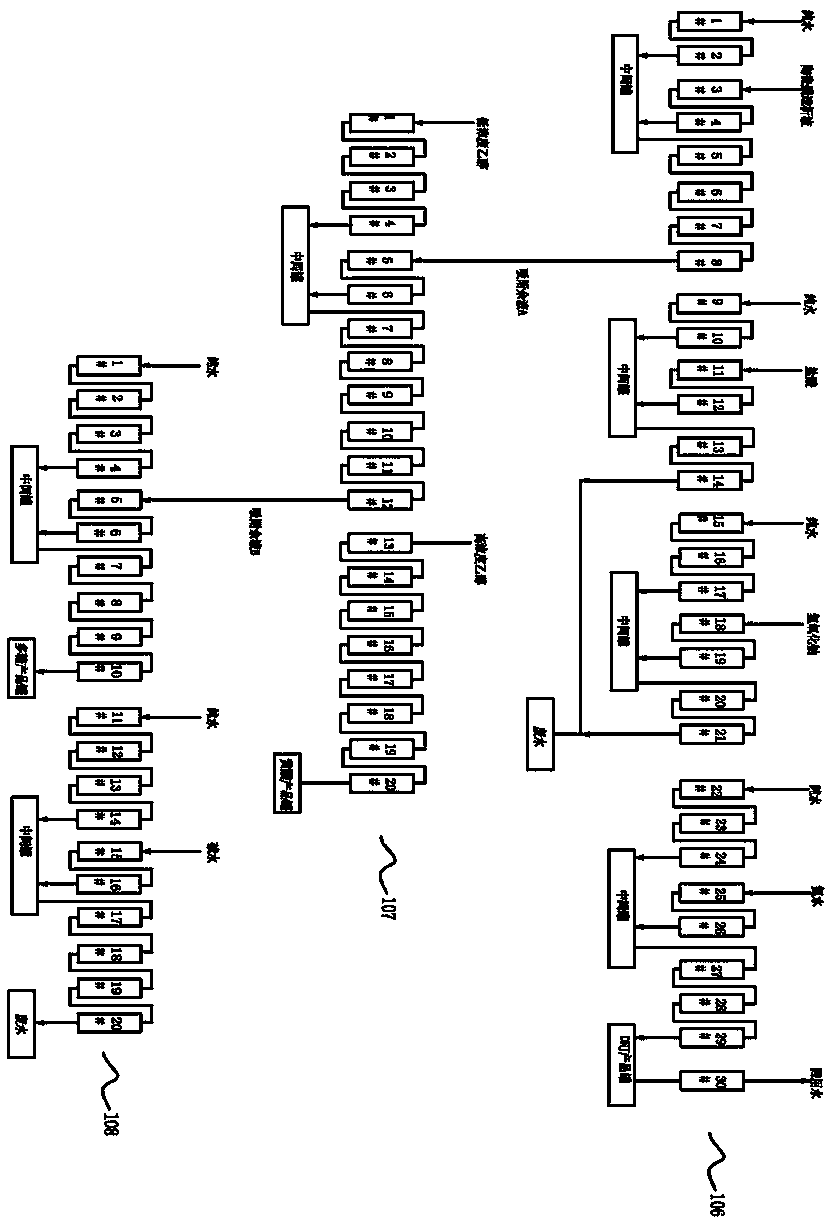

Method used

Image

Examples

Embodiment 1

[0075] Step 1: Weigh 40 kg of crushed mulberry leaves and mulberry branch powder, add 260 kg of water for ultrasonic extraction, and remove large particles through coarse filtration to obtain 240 L of filtrate;

[0076] Step 2: The filtrate enters the ceramic membrane system for clarification and removal of impurities. The operating pressure is 0.15Mpa, the pore size of the ceramic membrane is 200nm, the operating temperature is controlled within 60°C, and the continuous operation is 1000min. During the process, the concentrated solution is washed with water, and the average membrane flux is about 78LMH ( Liter / square meter per hour), to obtain 360L ceramic membrane dialysate;

[0077] Step 3: The ceramic membrane dialysate enters the roll-type reverse osmosis equipment for concentration, the operating pressure is 25bar, the operating temperature is controlled within 35°C, and the processing time is 470 minutes to obtain 324L of reverse osmosis product water and 36L of reverse ...

Embodiment 2

[0082] Step 1: Weigh 100kg of crushed mulberry leaves and mulberry branch powder, add 650kg of water for ultrasonic extraction, and remove large particles by coarse filtration to obtain 600L of filtrate

[0083] Step 2: The filtrate enters the ceramic membrane system for clarification and removal of impurities. The operating pressure is 3bar, the operating temperature is controlled within 60°C, the operating pressure is 0.5Mpa, the ceramic membrane pore size is 500nm, and the continuous operation is 920min. The volume is about 88LMH (liter / square meter per hour), and 900L ceramic membrane dialysate is obtained;

[0084] Step 3: The ceramic membrane dialysate enters the dish-type reverse osmosis pilot plant for concentration, the operating pressure is 69bar, the operating temperature is controlled within 35°C, and the treatment time is 348 minutes to obtain 555L of reverse osmosis product water and 45L of reverse osmosis concentrate;

[0085] Step 4: The reverse osmosis concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com