Semiconductor material wet surface process passivation method

A semiconductor and wet process technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unfavorable subsequent application of III-V semiconductor materials, decreased passivation effect, and sodium ion pollution, and achieve enhanced passivation. Chemical stability, inhibition of oxidative corrosion, and reduction of volatilization of toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

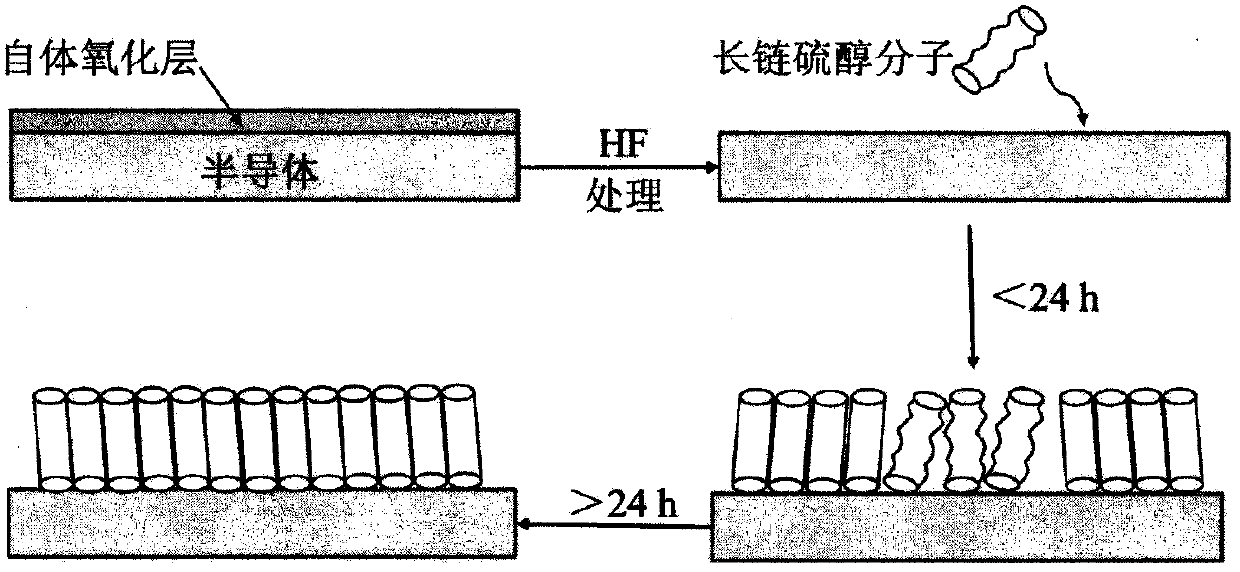

[0008] Step 1: Place the semiconductor wafer in acetone, ethanol, and deionized water for 5 to 10 minutes to ultrasonically clean it to remove organic contamination on the surface, and then rinse it with deionized water;

[0009] Step 2: Put the cleaned wafer into HF (HF:H 2 (O=1:1) soak in the solution for 3min to 10min to remove the thicker oxide layer on the wafer surface;

[0010] Step 3: Place the wafer in n-eicosanethiol (CH 3 [CH 2 ] 19 SH) in an ethanol solution, where the concentration of mercaptan is 5mM to 10mM, and the passivation is not less than 24h at room temperature;

[0011] Step 4: After the chip is taken out, put it into the isopropanol solution and sonicate it for not less than 5 minutes, and then dry it with high-purity nitrogen;

[0012] Step 5: The wafer is annealed under nitrogen condition, the temperature is 200±20°C, and the time is 30min±5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com