Solar photovoltaic loop heat pipe capillary copper pipe heat supply system with condenser connected in parallel

A photovoltaic loop and condenser technology, which is applied in the field of building energy conservation, can solve the problems of complex equipment, uneven heat dissipation, and low heat exchange efficiency, and achieve the effects of compact equipment structure, optimized utilization, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

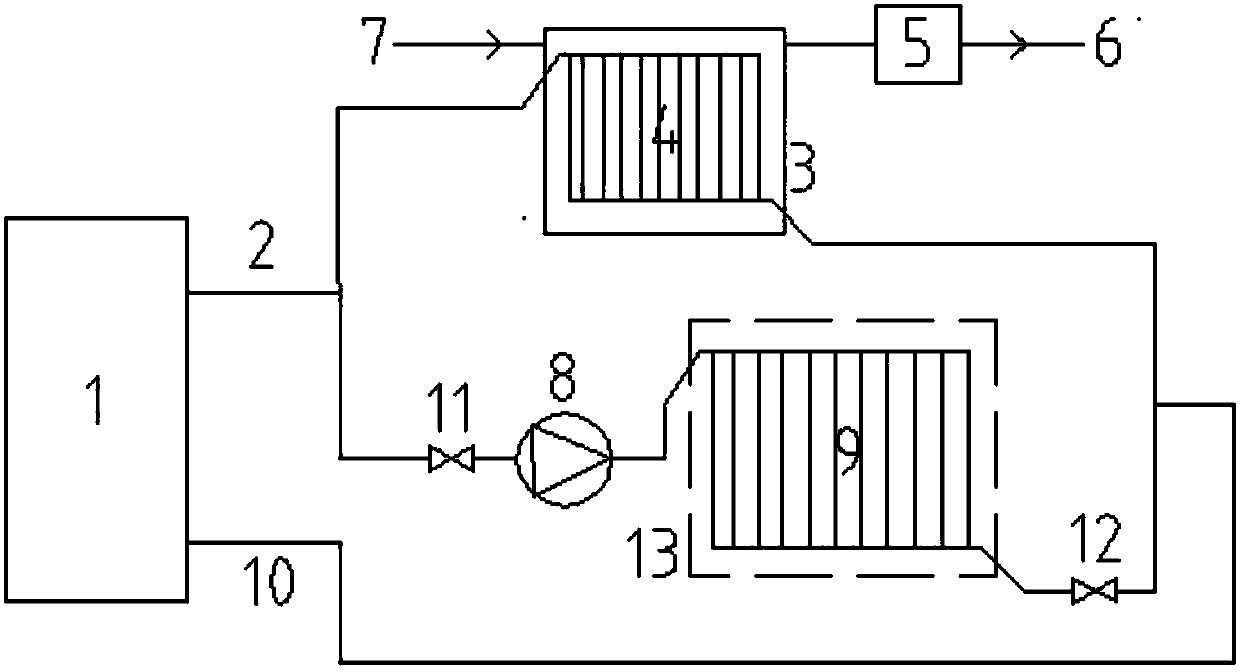

[0017] A solar photovoltaic loop heat pipe capillary copper tube heating system with condensers connected in parallel according to the present invention has a solar photovoltaic loop heat pipe capillary copper tube hot water loop and a solar photovoltaic loop heat pipe capillary copper tube floor radiation heating loop. Such as figure 1 As shown, the system includes a flat-plate solar photovoltaic / photothermal loop heat pipe heat collector / evaporator 1, a water tank 3, a capillary copper tube condenser 4, an electric heating device 5, a circulation pump 8, and a capillary copper tube floor radiation heating terminal 9. The first regulating valve 11 and the second regulating valve 12; in actual use, the capillary copper tube floor radiant heating end 9 is placed in the heating room 13, the capillary copper tube condenser 4 is placed in the water tank 3, and the left end of the water tank 3 It is connected to the tap water pipe 7, and its right end is connected to the water supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com