Aqueous compound fertilizer anti-blocking agent and preparation method thereof

An anti-caking agent and water-soluble technology, applied in the field of water-soluble compound fertilizer anti-caking agent and its preparation, can solve the problems of large consumption of mechanical oil, soil, water quality, crop pollution, etc., reduce cohesion, promote The effect of growth absorption and enhanced water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

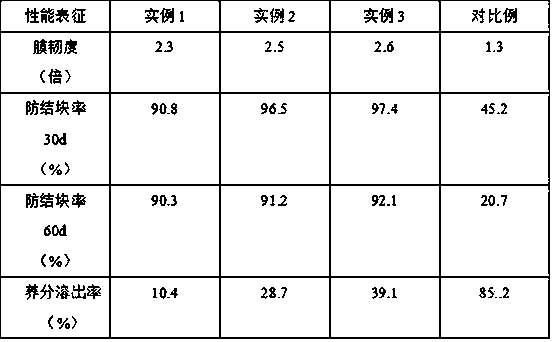

Examples

example 1

[0024] Take the potato residue and wash it with deionized water for 3 times, put it in a drying box, dry it at 105°C to constant weight, put it into a pulverizer and grind it, pass through a 60-mesh sieve to obtain potato residue powder, take 20g of potato residue powder, Add 200mL deionized water and mix well, heat and boil for 10min, add 0.4g cellulase after cooling to room temperature, stir and react at 300r / min for 20min in a constant temperature water bath at 40°C for 10min, then add 2% sodium carbonate solution Adjust the pH to 6, transfer to a centrifuge for centrifugation, evaporate the supernatant to dryness under reduced pressure to obtain water-soluble potato residue fiber, take 4g of water-soluble potato residue fiber, add it to 80g of isopropanol, and use 300r / min Stir for 10 minutes, then add 40g of 10% sodium hydroxide solution, stir for 1 hour, add 50g of 12% chloroacetic acid isopropanol solution, heat to 55°C for 4 hours, and use 5% acetic acid solution Adjus...

example 2

[0026] Take the potato residue and wash it with deionized water for 4 times, put it in a drying box, dry it at 107°C to constant weight, put it into a pulverizer and grind it, and pass through a 60-mesh sieve to obtain potato residue powder. Take 25g of potato residue powder, Add 250mL deionized water and mix well, heat and boil for 12min, add 0.5g cellulase after cooling to room temperature, stir and react at 350r / min for 25min in a constant temperature water bath at 45°C for 13min, then add 2% sodium carbonate solution Adjust the pH to 6, transfer to a centrifuge for centrifugation, evaporate the supernatant to dryness under reduced pressure to obtain water-soluble potato residue fiber, take 5g of water-soluble potato residue fiber, add it to 100g of isopropanol, and use 350r / min Stir for 15 minutes, then add 50g of 15% sodium hydroxide solution, stir for 1 hour, add 62g of 12% chloroacetic acid isopropanol solution, heat to 57°C for 4 hours, and use 5% acetic acid solution ...

example 3

[0028]Take the potato residue and wash it with deionized water for 5 times, put it in a drying box, dry it at 110°C to constant weight, put it into a pulverizer and grind it, pass through a 60-mesh sieve to obtain potato residue powder, take 30g of potato residue powder, Add 300mL deionized water and mix evenly, heat and boil for 15min, add 0.6g cellulase after cooling to room temperature, stir and react at 400r / min for 30min in a constant temperature water bath at 50°C for 15min, then add 2% sodium carbonate solution Adjust the pH to 7, transfer to a centrifuge for centrifugation, and evaporate the supernatant to dryness under reduced pressure to obtain water-soluble potato residue fibers. Take 6g of water-soluble potato residue fibers and add them to 120g of isopropanol, at 400r / min Stir for 20 minutes, then add 60g of 20% sodium hydroxide solution, stir for 2 hours, add 75g of 12% chloroacetic acid isopropanol solution, heat to 60°C for 5 hours, and use 5% acetic acid soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com