Anti-fog hydrophilic film as well as preparation method and application thereof

A hydrophilic film and anti-fog technology, applied in the field of coatings, can solve the problems of anti-fog film anti-fog effect and anti-fog duration to be further improved, and achieve the effects of long hydrophilicity, reduced seepage, and improved water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

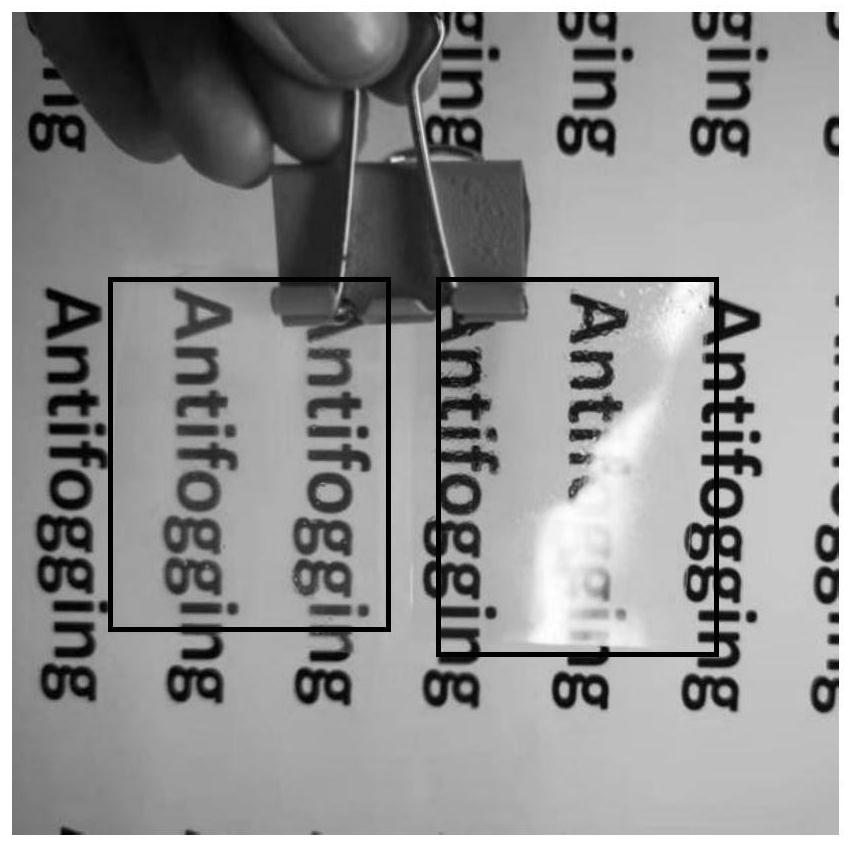

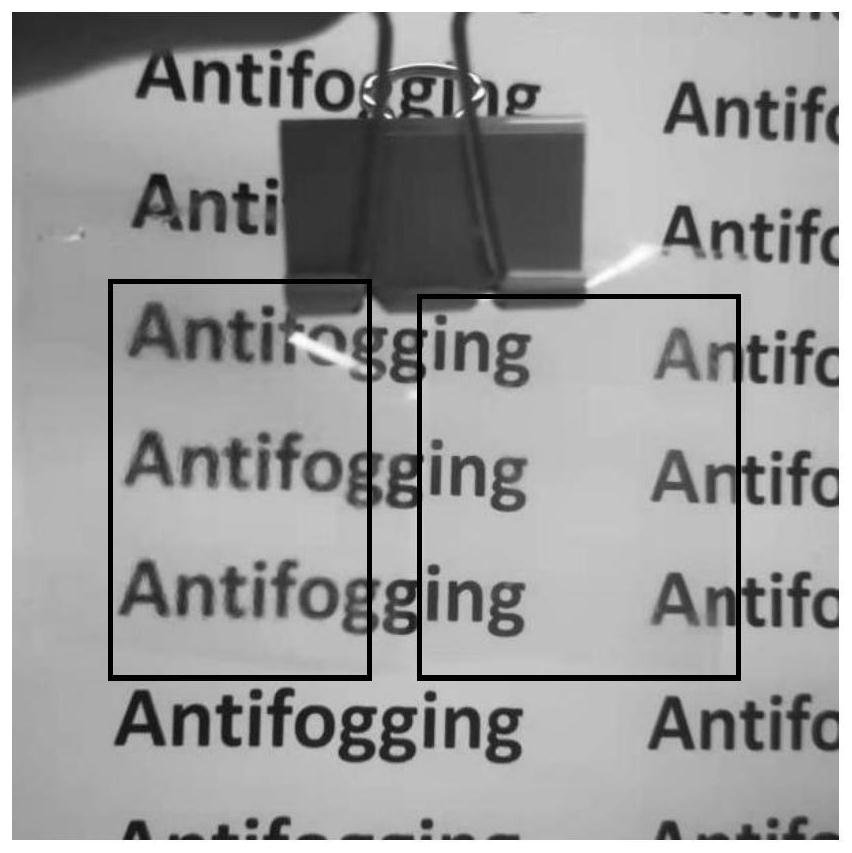

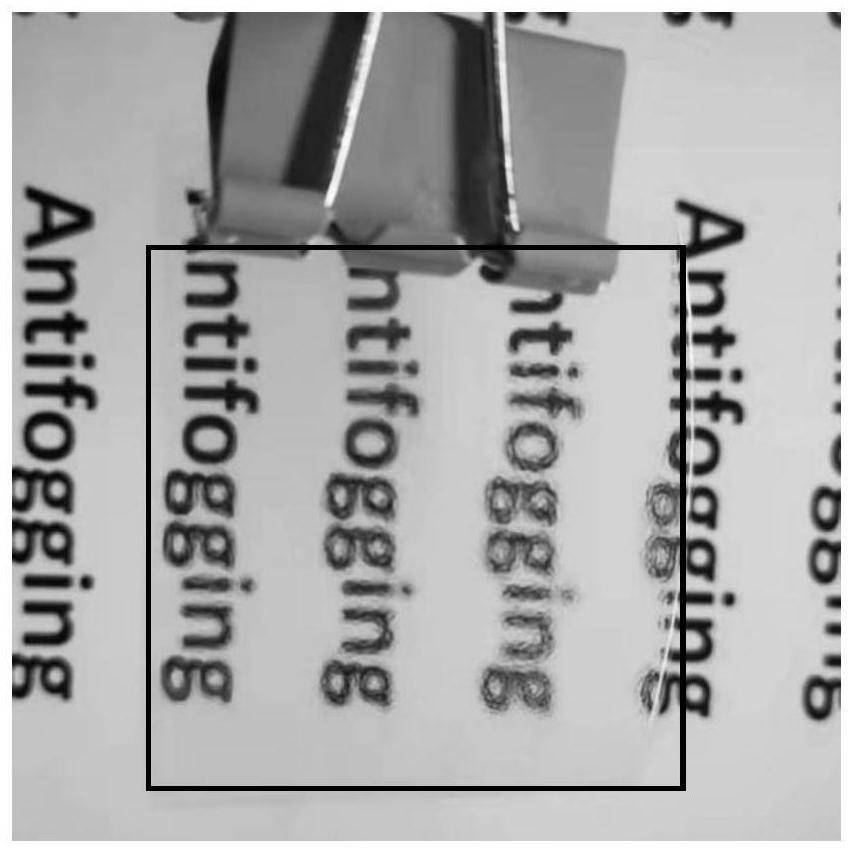

Image

Examples

Embodiment 1

[0054] In this embodiment, an anti-fog hydrophilic film is provided. The raw materials for the preparation of the anti-fog hydrophilic film include resin masterbatches and additives, and the additives include water-absorbing ionic liquids, ionic liquid surfactants and non-ionic Surfactant.

[0055] Wherein, based on the mass of the resin masterbatch as 100%, the content of the additive is 20%; based on the mass of the additive as 100%, the content of the water-absorbing ionic liquid is 30%, and the content of the ionic liquid surfactant is 10%. , the content of non-ionic surfactant is 60%; the resin masterbatch is TPU masterbatch; the water-absorbing ionic liquid is [BMIM][Ac]; the ionic liquid surfactant is 1-butyl-3-methylimidazole Hexafluorophosphate; non-ionic surfactant is perfluoroalkyl polyoxyethylene ether.

[0056] The preparation method comprises the following steps:

[0057] Mix the water-absorbing ionic liquid, ionic liquid-type surfactant and non-ionic surfactan...

Embodiment 2

[0059] In this embodiment, an anti-fog hydrophilic film is provided. The raw materials for the preparation of the anti-fog hydrophilic film include resin masterbatches and additives, and the additives include water-absorbing ionic liquids, ionic liquid surfactants and non-ionic Surfactant.

[0060] Wherein, the mass of the resin master batch is 100%, the content of the additive is 3%; the mass of the additive is 100%, the content of the water-absorbing ionic liquid is 20%, and the content of the ionic liquid surfactant is 20%. , the content of non-ionic surfactant is 60%; the resin masterbatch is TPU masterbatch; the water-absorbing ionic liquid is [BMIM][Cl]; the ionic liquid surfactant is 1-butyl-3-methylimidazole Hexafluorophosphate; non-ionic surfactant is alkylphenol ethoxylate.

[0061] The preparation method comprises the following steps:

[0062] Mix the water-absorbing ionic liquid, ionic liquid-type surfactant and non-ionic surfactant in the formulated amount for 6...

Embodiment 3

[0064] In this embodiment, an anti-fog hydrophilic film is provided. The raw materials for the preparation of the anti-fog hydrophilic film include resin masterbatches and additives, and the additives include water-absorbing ionic liquids, ionic liquid surfactants and non-ionic Surfactant.

[0065] Wherein, based on the mass of the resin masterbatch as 100%, the content of the additive is 40%; based on the mass of the additive as 100%, the content of the water-absorbing ionic liquid is 50%, and the content of the ionic liquid surfactant is 5%. , the content of non-ionic surfactant is 45%; the resin masterbatch is TPU masterbatch; the water-absorbing ionic liquid is [BMIM][Br]; the ionic liquid surfactant is 1-butyl-3-methylimidazole Tetrafluoroborate; the nonionic surfactant is polyether modified polydimethylsiloxane.

[0066] The preparation method comprises the following steps:

[0067] Mix the water-absorbing ionic liquid, ionic liquid-type surfactant and non-ionic surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com