Shock-absorption electric vehicle for transferring liquid-state explosives between workshops

A technology of electric vehicles and explosives, which is applied in the direction of freight vehicles, motor vehicles, and goods transport vehicles, etc. It can solve the problems of inconvenient maintenance, aggravated vibration, pin or screw falling off, etc., and achieves convenient inspection and maintenance, adding insulation boxes, Effects with controllable amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

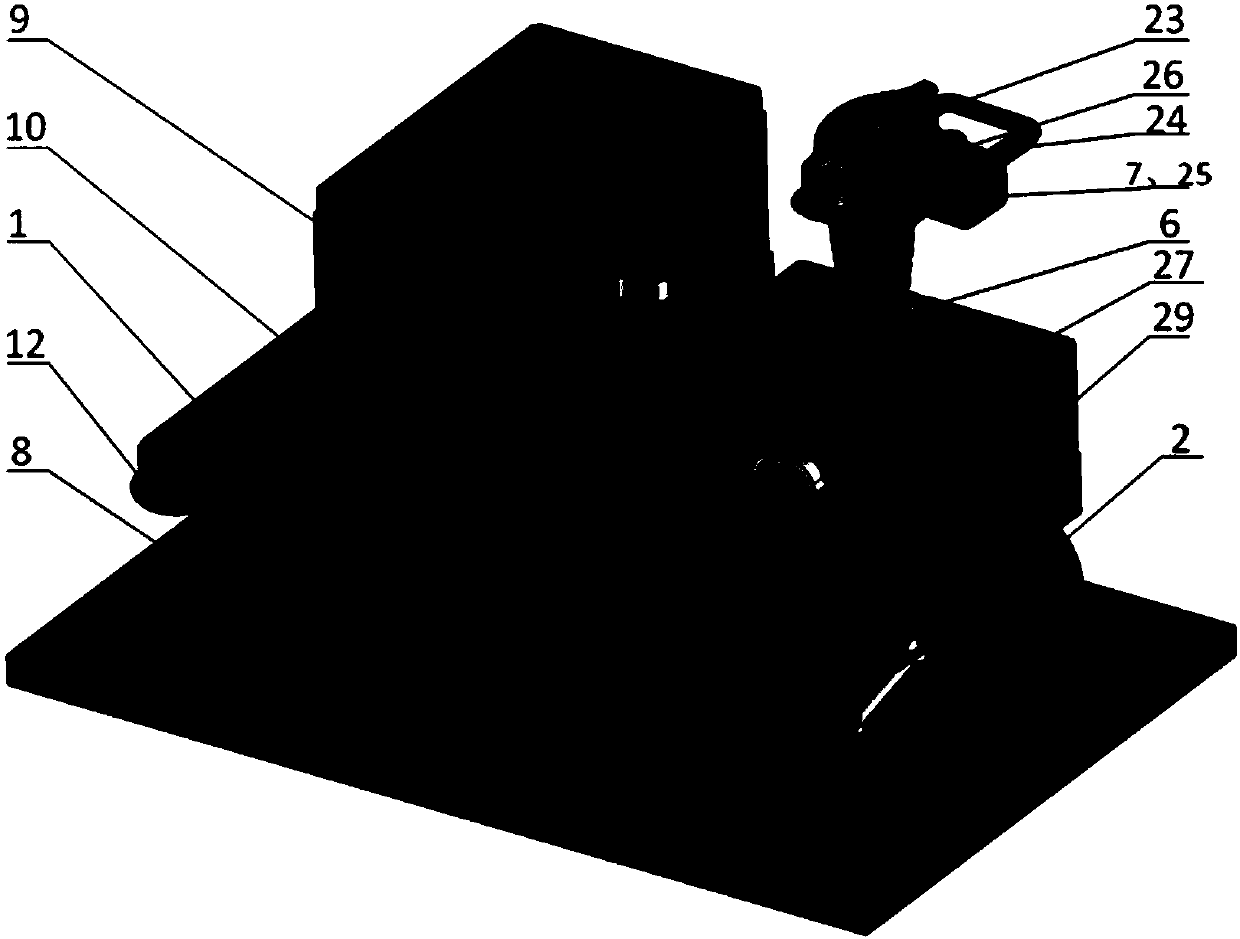

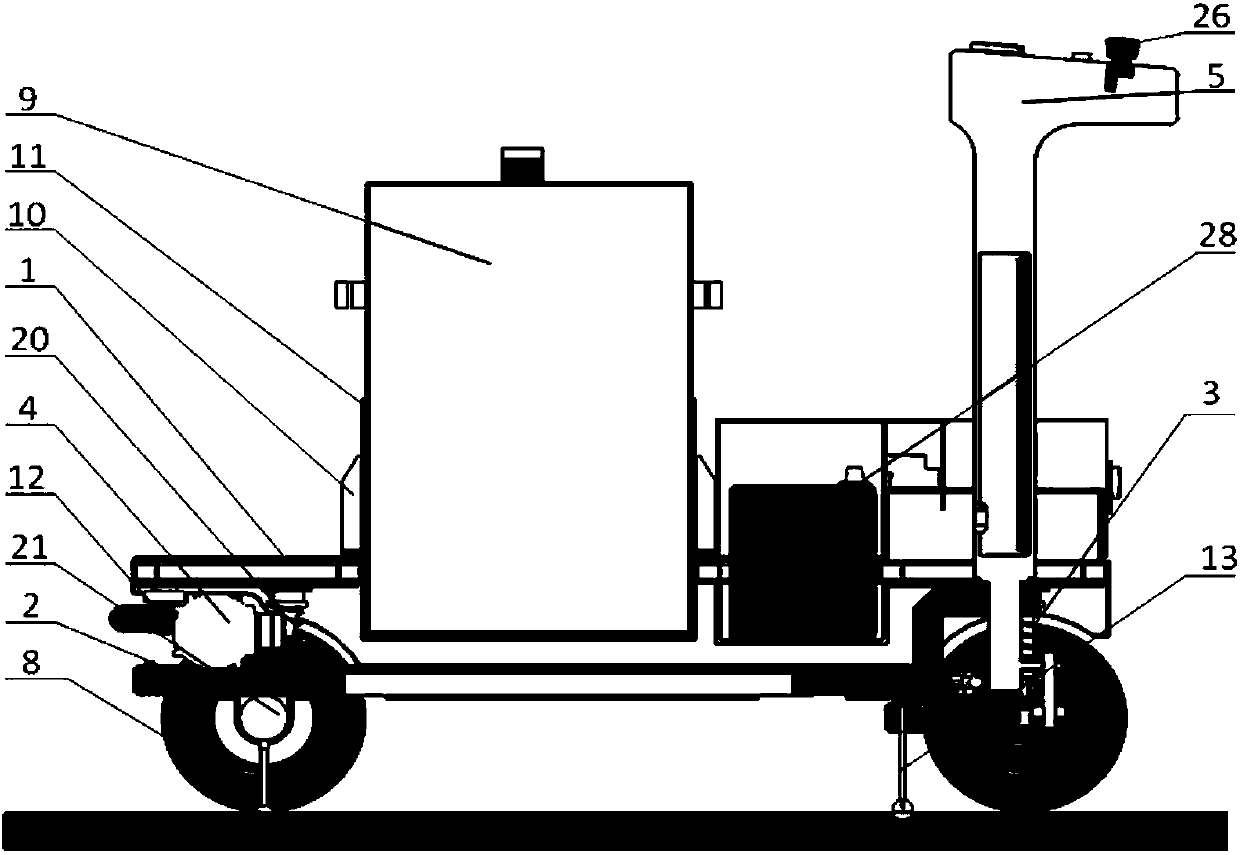

[0031] see figure 1 , 2 , a shock-absorbing electric car for liquid explosives room transfer of the present invention, as can be seen from the figure: the equipment consists of a car body 1, an axle 2, a shock-absorbing system 3, a drive system 4, a control system 5, Power supply system 6, braking system 7, wheel set 8, incubator 9 etc. are made up of parts, and the rated load of present embodiment electric car is 60kg, is used for the workshop transshipment of ammonium azide nitrate.

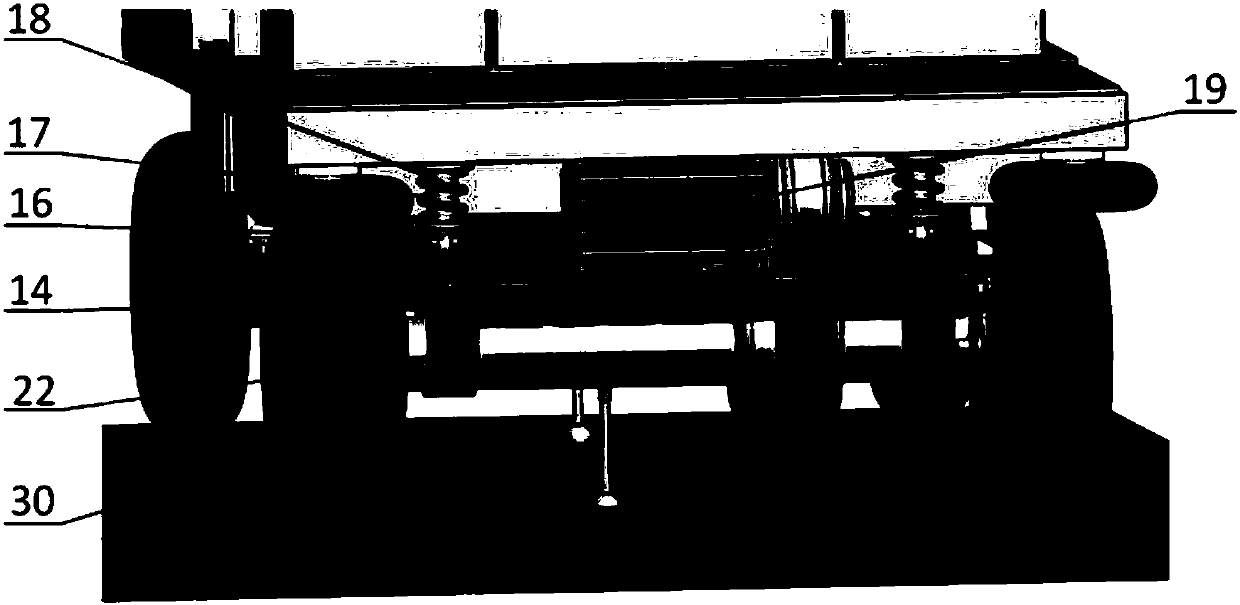

[0032] see image 3 , the axle 2 and the vehicle body 1 are connected through a shock absorbing system 3; the shock absorbing system 3 includes a shock absorbing spring 17 and a guide column 18, and the type of the shock absorbing system shock absorbing spring is cold coil compression Spring, the material is 60Si2MnA, type C; the impact sensitivity of ammoniu...

Embodiment 2

[0039] The rated load of the electric vehicle of this embodiment is 60kg, which is used for the transfer of nitroglycerin in the workshop.

[0040] see image 3 , the axle 2 and the vehicle body 1 are connected through a shock absorbing system 3; the shock absorbing system 3 includes a shock absorbing spring 17 and a guide column 18, and the type of the shock absorbing system shock absorbing spring is cold coil compression Spring, the material is 60Si2MnA, type C; the impact sensitivity of nitroglycerin liquid explosive is 1, and the rated load is 60kg. According to the functional relationship between the resonant frequency of the shock-absorbing electric vehicle, the sensitivity of liquid explosive and the weight of liquid explosive f(HZ)=0.57x-32y The resonant frequency is calculated to be 2HZ. According to the spring selection formula, the diameter of the spring steel wire is d=25mm, the middle diameter of the spring is D=140mm, and the number of turns is 8.

[0041] see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com