Electromobile metal plate paint spraying process

A technology for electric vehicles and sheet metal, applied to coatings, pre-treated surfaces, reflective/signal coatings, etc., can solve the problems of poor water resistance, poor insulation, and poor wear resistance of ordinary coatings, and achieve high temperature resistance. Good flame retardancy and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

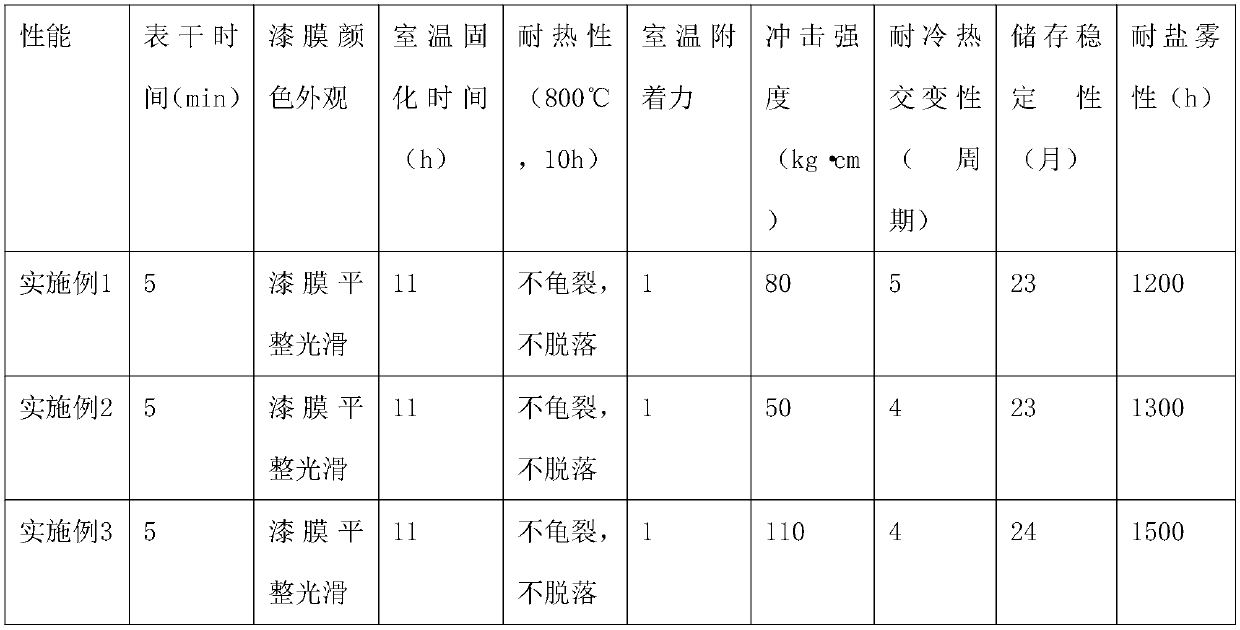

Examples

Embodiment 1

[0023] An electric vehicle sheet metal painting process, including the following steps:

[0024] (1) Preparation: Derusting and cleaning the surface of sheet metal, using sandpaper to remove rust; after derusting, clean the blank surface with glacial acetic acid solution, wipe clean the greasy parts with cotton silk, etc., and dry for 6 minutes. Apply a layer of latex on the sheet metal, and after the latex on the sheet metal is dry, scrape putty powder on the parts of the sheet metal that need to be painted, and then polish it after drying;

[0025] (2) Spray paint: cover the parts that do not need spray paint, and spray paint on the sheet metal by spray paint and dry it;

[0026] (3) Drying: when the atmospheric temperature is above 20℃, dry naturally, and the drying time is not less than 20 minutes; the atmospheric temperature is below 20℃;

[0027] (4) Polishing: Polish the painted sheet metal and paste the logo;

[0028] (5) Inspection: The painted surface shall be free of slip ma...

Embodiment 2

[0033] An electric vehicle sheet metal painting process, including the following steps:

[0034] (1) Preparation: Derusting and cleaning the surface of sheet metal, using sandpaper to remove rust; after derusting, clean the blank surface with glacial acetic acid solution, wipe clean the greasy parts with cotton silk, etc., and dry for 6 minutes. Apply a layer of latex on the sheet metal, and after the latex on the sheet metal is dry, scrape putty powder on the parts of the sheet metal that need to be painted, and then polish it after drying;

[0035] (2) Spray paint: cover the parts that do not need spray paint, and spray paint on the sheet metal by spray paint and dry it;

[0036] (3) Drying: when the atmospheric temperature is above 20℃, dry naturally, and the drying time is not less than 20 minutes; the atmospheric temperature is below 20℃;

[0037] (4) Polishing: Polish the painted sheet metal and paste the logo;

[0038] (5) Inspection: The painted surface shall be free of slip ma...

Embodiment 3

[0043] An electric vehicle sheet metal painting process, including the following steps:

[0044] (1) Preparation: Derusting and cleaning the surface of sheet metal, using sandpaper to remove rust; after derusting, clean the blank surface with glacial acetic acid solution, wipe clean the greasy parts with cotton silk, etc., and dry for 6 minutes. Apply a layer of latex on the sheet metal, and after the latex on the sheet metal is dry, scrape putty powder on the parts of the sheet metal that need to be painted, and then polish it after drying;

[0045] (2) Spray paint: cover the parts that do not need spray paint, and spray paint on the sheet metal by spray paint and dry it;

[0046] (3) Drying: when the atmospheric temperature is above 20℃, dry naturally, and the drying time is not less than 20 minutes; the atmospheric temperature is below 20℃;

[0047] (4) Polishing: Polish the painted sheet metal and paste the logo;

[0048] (5) Inspection: The painted surface shall be free of slip ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com