Silicon carbide surface treating agent

A technology of surface treatment agent and silicon carbide, which is applied in the field of surface treatment, can solve the problems of high cost, poor stability of silicon carbide, large dosage, etc., and achieve the goals of reducing usage and production cost, improving usage effect, good adsorption and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

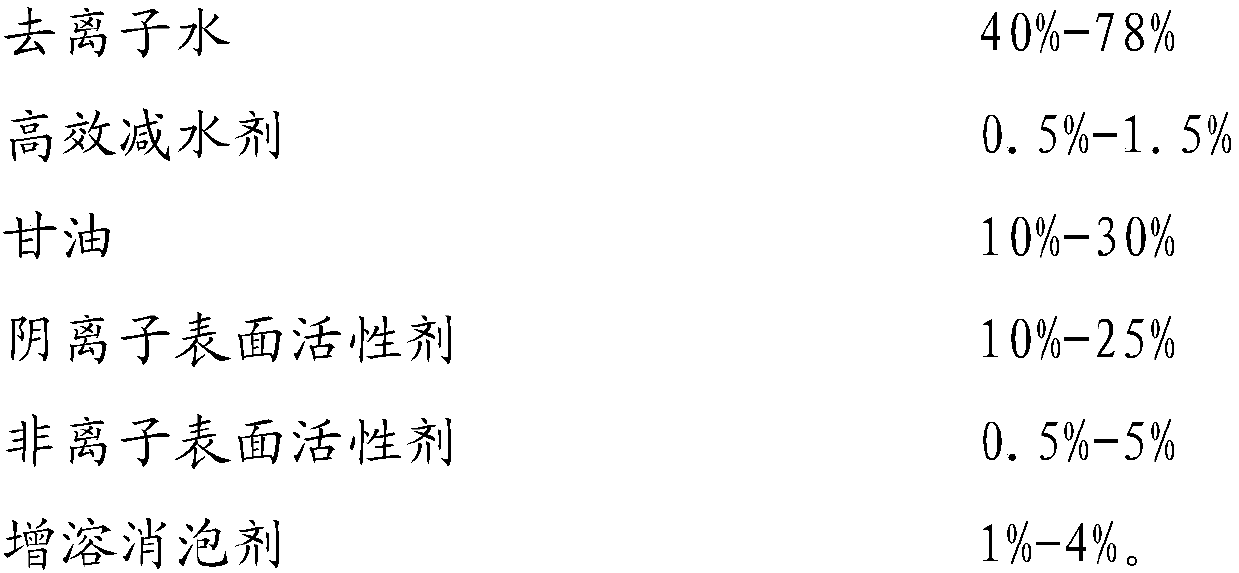

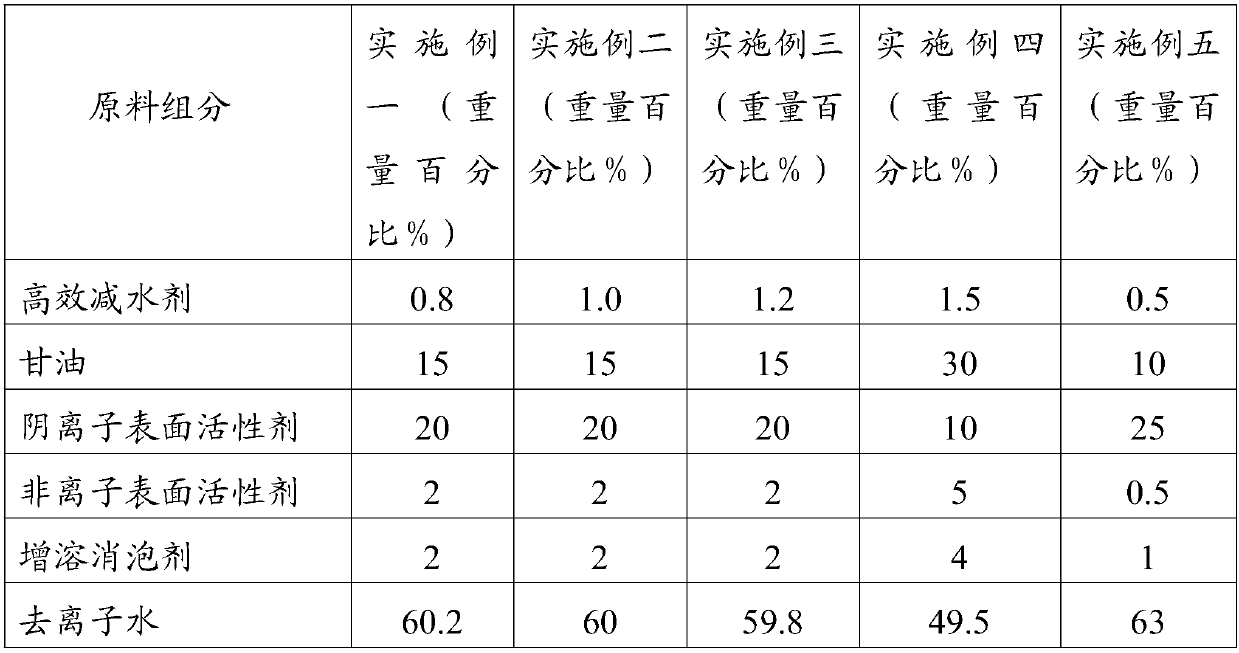

[0016] See Table 1 for the weight ratio of raw materials in Embodiment 1, Embodiment 2, Embodiment 3, Embodiment 4 and Embodiment 5.

[0017] Table 1

[0018]

[0019] In Table 1, the superplasticizer can be one of melamine-based superplasticizers, naphthalene-based superplasticizers, and polycarboxylic acid-based superplasticizers. Preferably, the high-efficiency water reducer is YH-22 melamine-based high-efficiency water reducer.

[0020] In Table 1, the anionic surfactant may be sodium dodecylbenzenesulfonate. Of course, the anionic surfactant can also be a sulfonate-type anionic surfactant, a sulfate-type anionic surfactant, etc., which will not be repeated here.

[0021] In Table 1, the nonionic surfactant can be one of fatty alcohol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, and cetyl alcohol polyoxyethylene ether. Preferably, the nonionic surfactant is fatty alcohol polyoxyethylene ether.

[0022] In Table 1, the solubilizing and defoaming agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com