Pretreatment method and system for wastewater in technology for preparing epoxy chloropropane by propylene high-temperature chlorination process

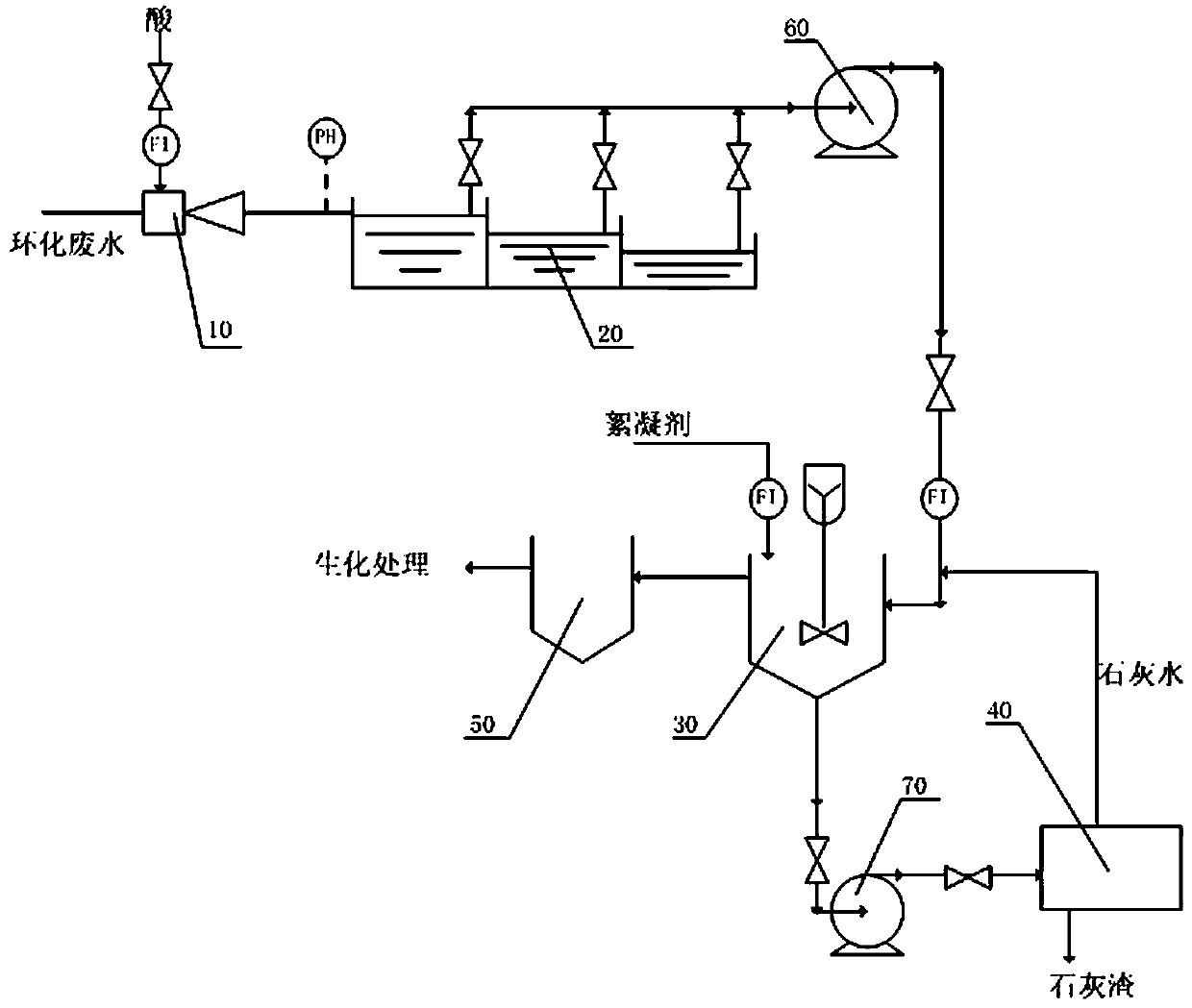

An epichlorohydrin and high-temperature chlorination technology, applied in the chemical industry, can solve the problems of low efficiency, complicated pretreatment process, and high content of suspended solids in wastewater, and achieve the effects of simple process flow, favorable biochemical treatment, and high treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) Obtain the cyclization wastewater in the process of preparing epichlorohydrin by high-temperature chlorination of propylene, the pH value of the cyclization wastewater is 10.9, and the suspended solid content is 2306mg / l.

[0081] (2) Mix the cyclization wastewater with 30% hydrochloric acid to obtain a mixed solution, the pH of which is 8.9.

[0082] (3) Mix the above mixed liquid with 1.2‰ aluminum sulfate aqueous solution, stir and settle to obtain clear liquid and sediment.

[0083] The sediment is centrifuged to obtain lime water and lime residue. Return the lime water to repeat step (3).

[0084] The water quality of the collected supernatant was clear and transparent, and the content of suspended solids in the supernatant was 47 mg / l.

[0085] Lime slag is concentrated and calcined into quicklime for recycling.

Embodiment 2

[0087] (1) Obtain the cyclization wastewater in the process of preparing epichlorohydrin by high-temperature chlorination of propylene, the pH value of the cyclization wastewater is 10.6, and the suspended matter content is 2506 mg / l.

[0088] (2) Mix the cyclization wastewater with 50% sulfuric acid to obtain a mixed solution, the pH of which is 8.7.

[0089] (3) Mix the above mixed liquid with 1.4‰ ferric chloride aqueous solution, stir and settle to obtain clear liquid and sediment.

[0090] The water quality of the collected supernatant was clear and transparent, and the content of suspended solids in the supernatant was 53 mg / l.

Embodiment 3

[0092] (1) Obtain the cyclization wastewater in the process of preparing epichlorohydrin by high-temperature chlorination of propylene, the pH value of the cyclization wastewater is 11.2, and the suspended solid content is 2440 mg / l.

[0093] (2) Mix the cyclization wastewater with 69% nitric acid to obtain a mixed solution, the pH of which is 8.8.

[0094] (3) Mix the above mixed solution with 2.3‰ polysilicate ferric sulfate aqueous solution, stir and settle to obtain clear liquid and sediment.

[0095] The sediment is centrifuged to obtain lime water and lime residue. Return the lime water to repeat step (3).

[0096] The water quality of the collected supernatant was clear and transparent, and the content of suspended solids in the supernatant was 48 mg / l.

[0097] Lime slag is concentrated and calcined into quicklime for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com