Automatic gypsum line cutting device

A gypsum wire and transmission technology, which is applied to stone processing tools, stone processing equipment, manipulators, etc., can solve the problems of poor cutting stability, inability to automatically cut gypsum wires of different lengths, and fast tool damage, so as to achieve stable operation and improve cutting Efficiency, noise removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

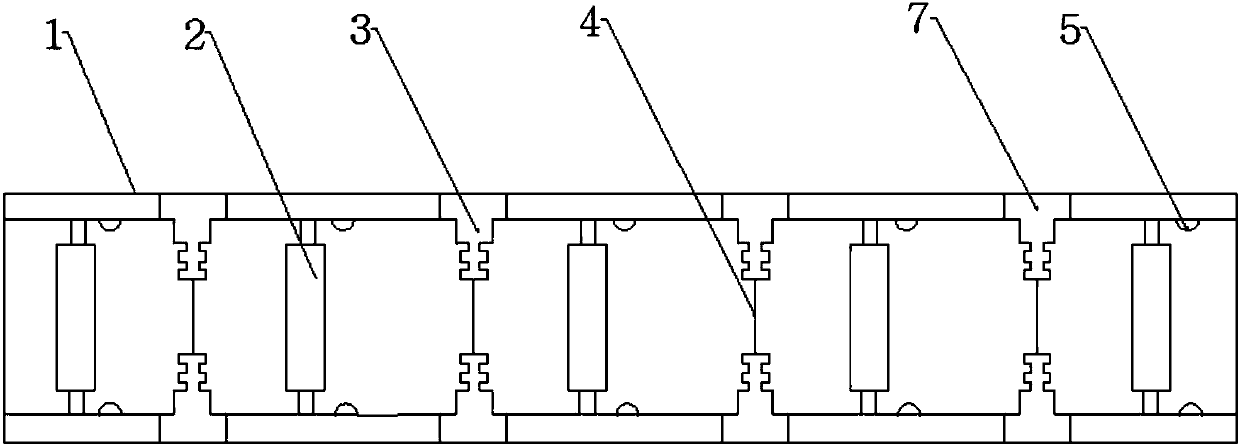

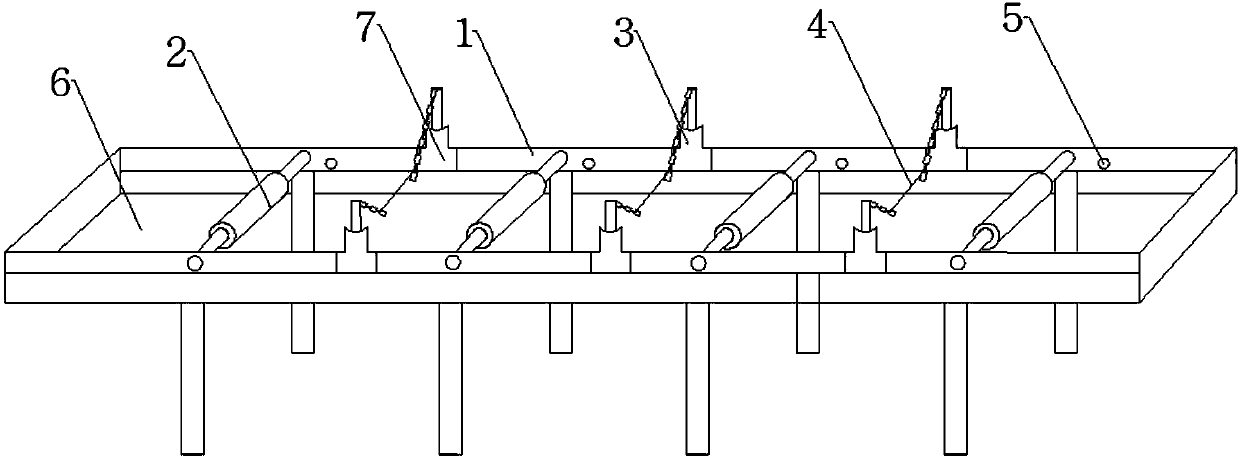

[0026] An automatic thread cutting device for a plaster line, comprising a working platform 1, a transmission device, a cutting device and a control device; the transmission device, the cutting device and the control device are all arranged on the working platform 1, and the transmission device includes a transmission roller 2, a transmission belt and a motor; The cutting device includes a manipulator 3, a mounting seat 7 and an emery wire 4; two sides of the working platform 1 are equidistantly provided with conveying rollers 2, the conveying rollers 2 are connected to the conveyor belt, and the motor is connected to the conveyor belt; the mounting seat 7 is arranged between the two conveying rollers 2 Between them, the manipulator 3 is installed on the mounting base 7, and the emery wire 4 is connected to the manipulator 3 on the other side through the manipulator 3 on one side, and the manipulator 3 is electrically connected to the control device.

[0027] The control device...

Embodiment 2

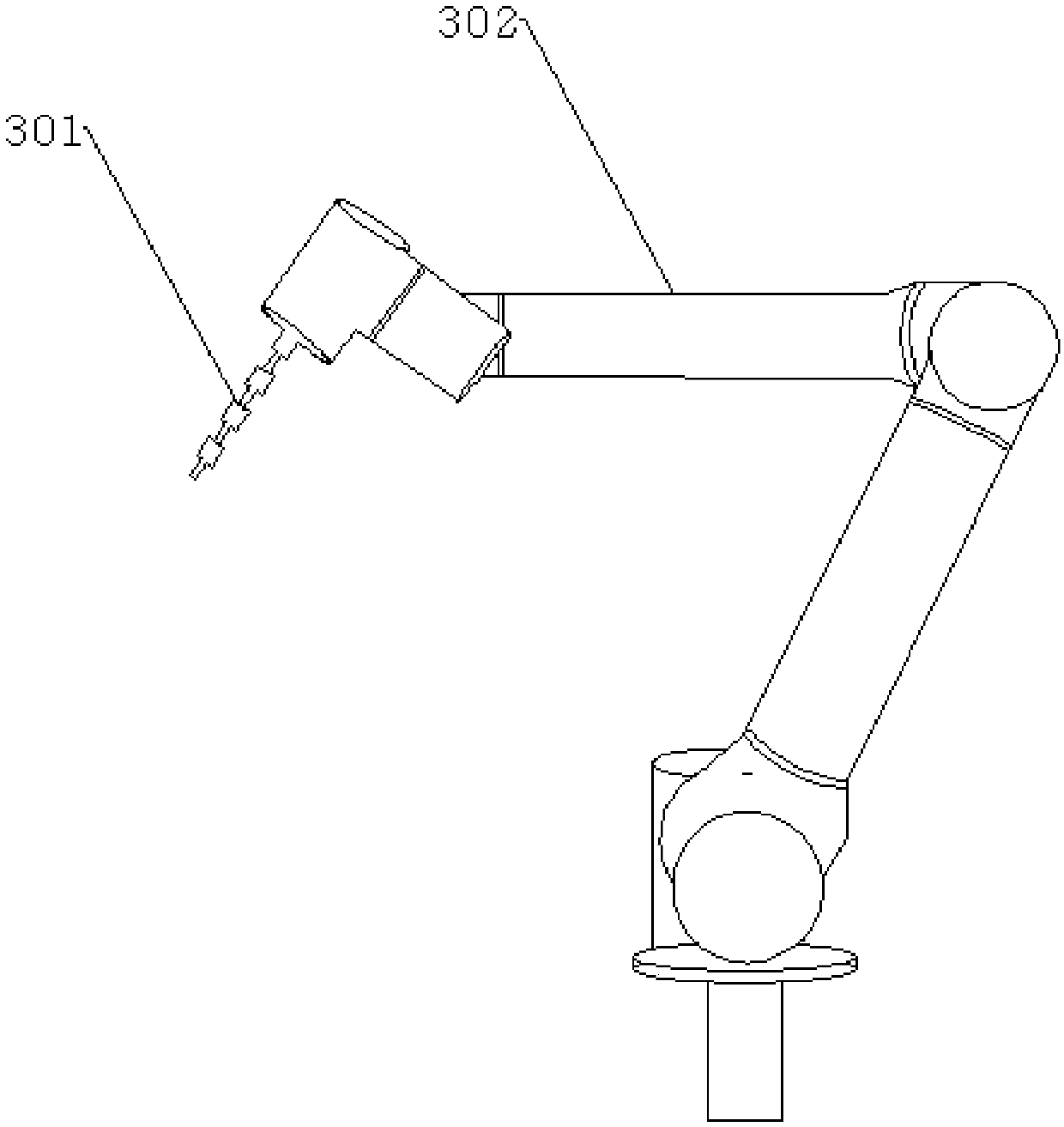

[0035]After the automatic thread cutting device is powered on, the motor starts, the conveyor belt set on the working platform 1 is connected to the conveyor roller 2, the conveyor roller 2 starts to rotate, and the gypsum thread placed on the conveyor roller 2 starts to move forward. If you need to cut different lengths For the plaster line, the length parameter needs to be set on the control device side. The infrared sensor 5 set on the side of the conveying roller 2 detects whether the plaster line has passed. When the processor receives the infrared sensor data 5 and processes it, it judges the equidistant number of the data to be cut. , then trigger the control part of the manipulator at the corresponding position, the control part triggers the motion mechanism 302 to move downward, the control part triggers the hand part 301 to tighten the emery wire 4, and when it moves down to the surface of the gypsum wire, it continues to cut down. After the cutting is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com