Cloth cutting device

A technology of cutting device and pressing device, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problems of fabric slack, different elasticity of fabrics, and increased labor costs, so as to reduce the degree of deformation of fabrics and smooth winding Wrinkle-free and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

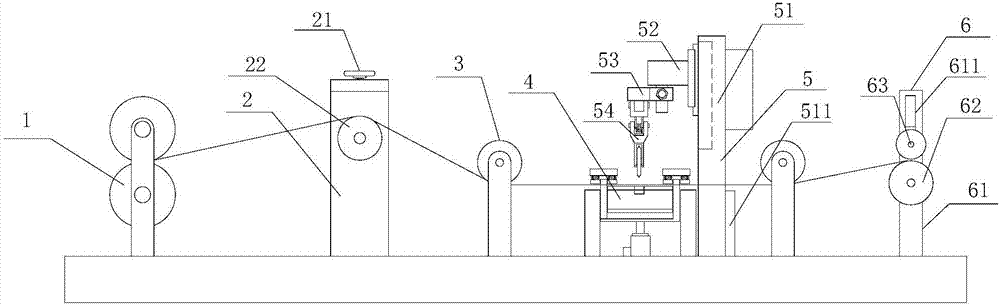

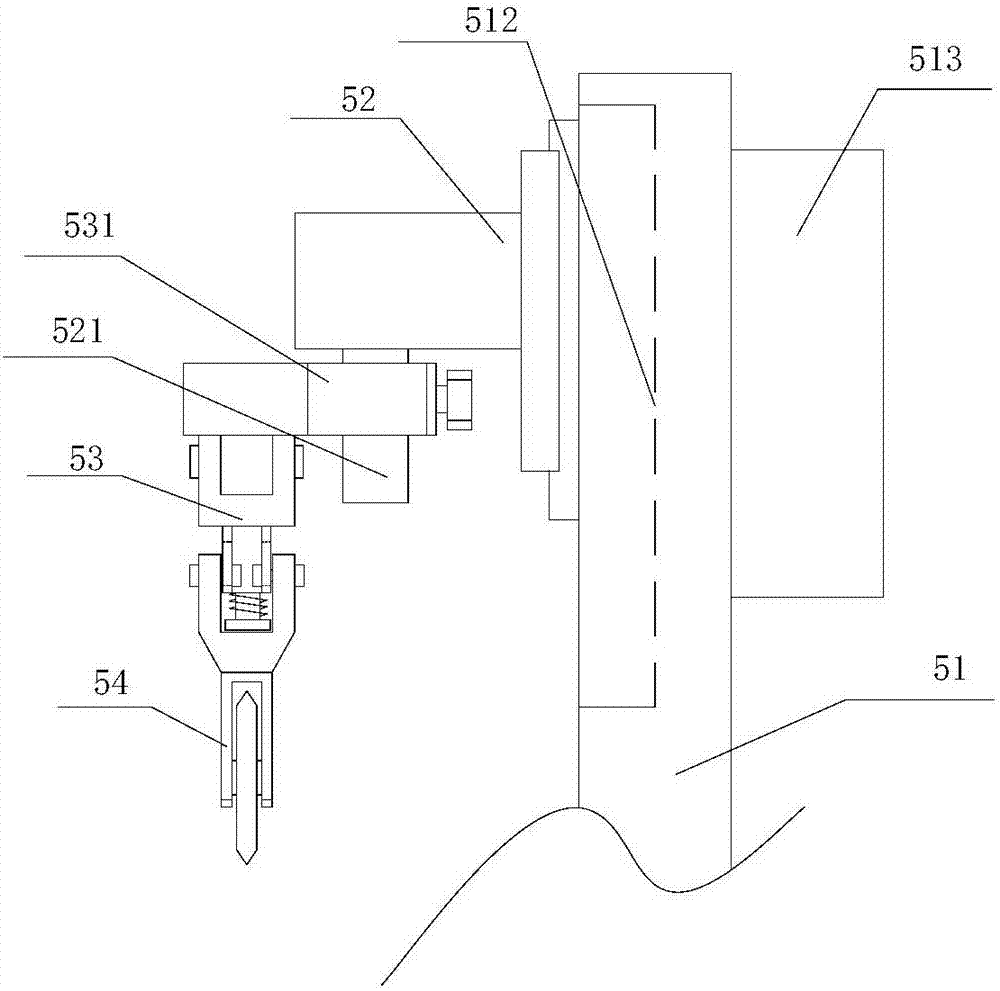

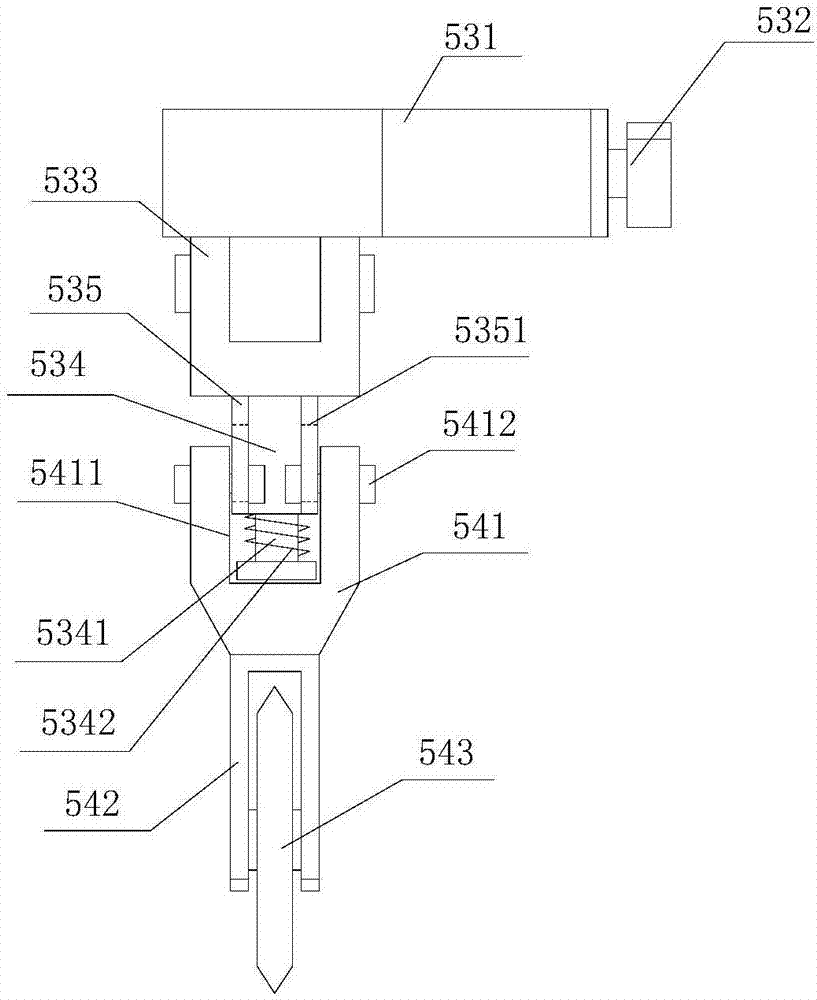

[0022] refer to Figure 1 to Figure 5 A fabric cutting device of the present invention includes a conveying roller device 1, an adjustable guide roller mechanism 2, an auxiliary roller assembly 3, a pressing device 4, a cutting device 5 and a winding device 6, and the two adjustable guide roller mechanisms 2 An adjustment device 21 is provided on the side, and a guide roller assembly 22 is installed between the adjustment devices 21. A knife seat 41 is provided on the pressing device 4, and a pressing mechanism 43 is provided on both sides of the knife seat 41. A cutting device 5 is provided above the pressing device 4, and auxiliary roller assemblies 3 are provided on both sides of the cutting device 5, and a mounting frame 51 is provided on the cutting device 5, and a vertical Sliding seat 512, horizontal sliding seat 52 is installed on the described vertical sliding seat 512, driving power box 513 is installed on the side wall of described installation frame 51, described d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com