Surface modification method for composite lithium nickel manganese oxide positive electrode material

A technology of lithium nickel manganate and cathode material, which is applied in the field of surface modification of composite lithium manganate cathode material, can solve problems such as affecting electrochemical performance, improve rate and cycle performance, maintain stable structure, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

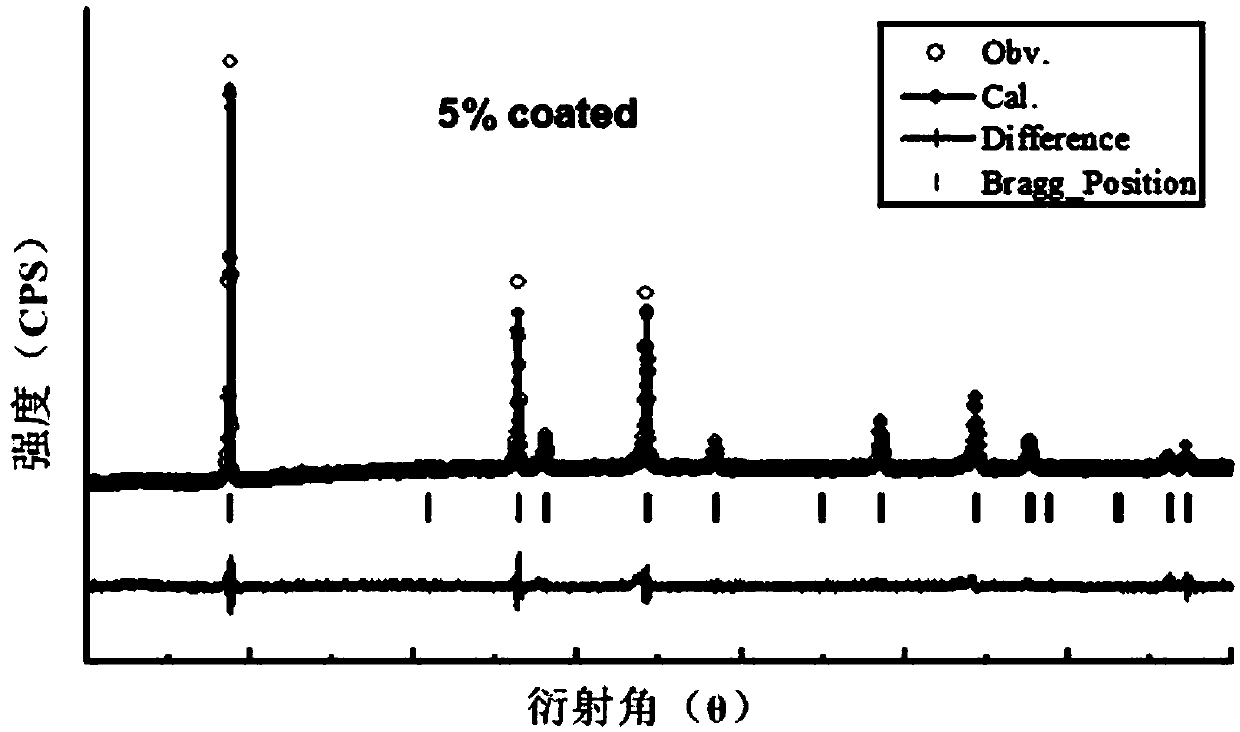

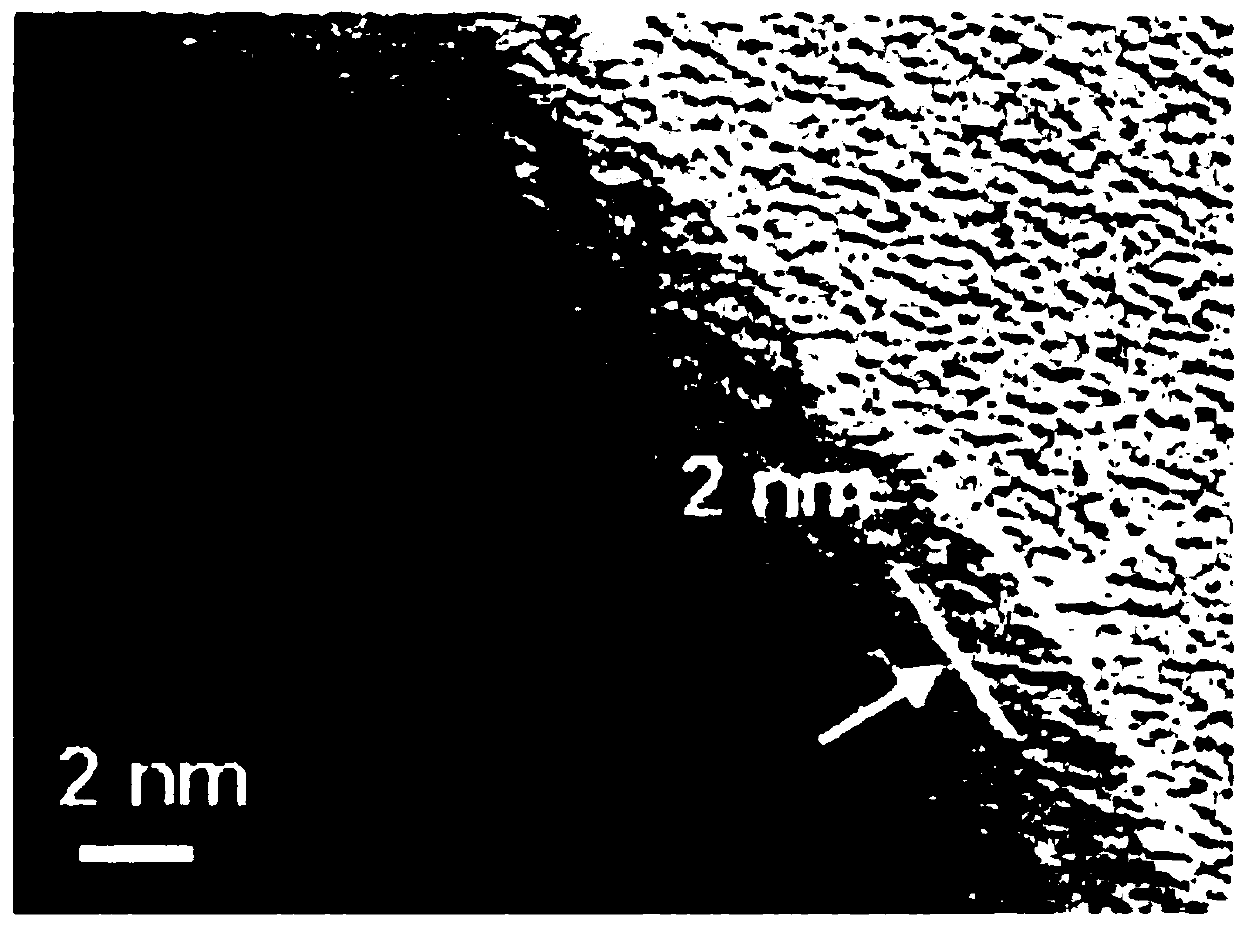

Method used

Image

Examples

Embodiment 1

[0027] (1) Press Li: Mn: Ni: The element molar ratio of Y is 1:1.495:0.495:0.01, accurately weigh lithium hydroxide, manganese nitrate, nickel nitrate, yttrium nitrate and dissolve in deionized water respectively to form a solution, then Add lithium hydroxide solution, manganese nitrate solution, nickel nitrate solution and yttrium nitrate solution to the citric acid solution drop by drop. After stirring for 2 hours, add ammonia water dropwise to keep the pH value of the mixed solution at 7. Under stirring conditions, heat the mixed solution to 80°C until the sol is formed, and then keep the obtained sol at 100°C for 12 hours to form a xerogel; pre-calcine the xerogel in a muffle furnace at 300°C for 8 hours, and after grinding, heat-treat at 800°C for 10 hours. Obtain yttrium-doped lithium nickel manganese oxide material LiMn 1.495 Ni 0.495 Y 0.01 o 4;

[0028] (2) Set [Y 1-x Mg x ][Cr 1-x-y sn y Ga z ]O 3 The yttrium-doped lithium nickel manganese oxide material wa...

Embodiment 2

[0034] (1) Press Li: Mn: Ni: The element molar ratio of Y is 1:1.475:0.475:0.05, accurately weigh lithium acetate, manganese sulfate, nickel sulfate, yttrium sulfate, and dissolve in deionized water respectively to form a solution, then Add lithium acetate solution, manganese sulfate solution, nickel sulfate solution and yttrium sulfate solution to the citric acid solution drop by drop, after stirring for 3 hours, add ammonia water dropwise to keep the pH value at 8, and heat the mixed solution to 80°C while stirring , until the sol is formed, and then the obtained sol is kept at 110°C for 15h to form a xerogel, and the obtained xerogel is pre-fired in a muffle furnace at 400°C for 7h, and after grinding, it is heat-treated at 800°C for 7h to obtain Yttrium-doped lithium nickel manganese oxide material;

[0035] (2) Set [Y 1-x Mg x ][Cr 1-x-y sn y Ga z ]O 3 The yttrium-doped lithium nickel manganese oxide material was dispersed in deionized water at a mass ratio of 0.05:...

Embodiment 3

[0037] (1) According to the element molar ratio of Li:Mn:Ni:Y as 1:1.49:0.49:0.02, accurately weigh lithium nitrate, manganese chloride, nickel chloride, and yttrium chloride, and dissolve them in deionized water to form a solution , then lithium nitrate solution, manganese chloride solution, nickel chloride solution, and yttrium chloride solution were added dropwise to the citric acid solution, and after stirring for 4 hours, ammonia water was added dropwise to keep the pH value at 8. Under stirring conditions, the mixed The solution was heated to 60°C until the sol was formed, and then the obtained sol was kept at 120°C for 20 hours to form a xerogel; the xerogel was pre-fired in a muffle furnace at 450°C for 7 hours, and after grinding, it was heat-treated at 850°C 8h just obtains yttrium-doped lithium nickel manganese oxide material;

[0038] (2) Set [Y 1-x Mg x ][Cr 1-x-y sn y Ga z ]O 3 The yttrium-doped lithium nickel manganese oxide material was dispersed in deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com