Method and device for collecting heat dissipation water vapor at top of thermal power plant circulating water cooling tower

A cooling tower, circulating water technology, applied in water shower coolers, heat exchange equipment, heat exchanger types, etc., can solve problems such as water waste, save industrial water, reduce consumption, and improve reuse rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

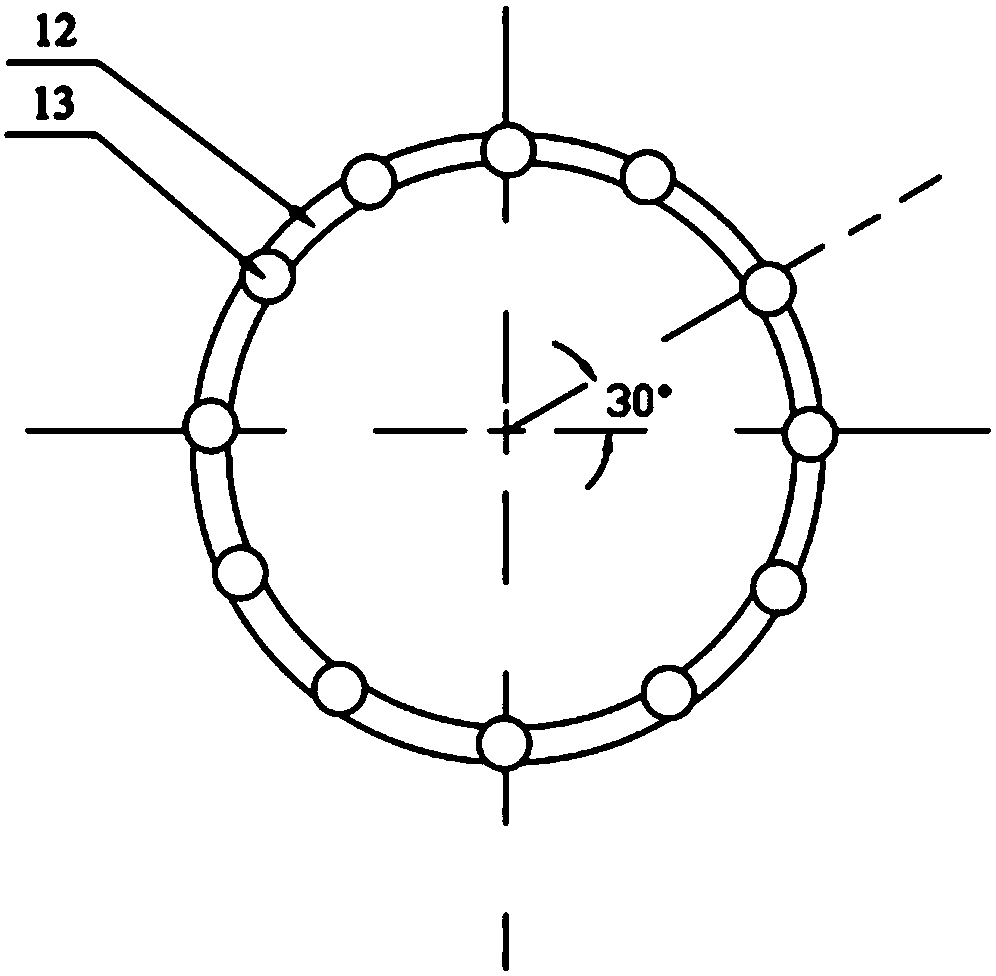

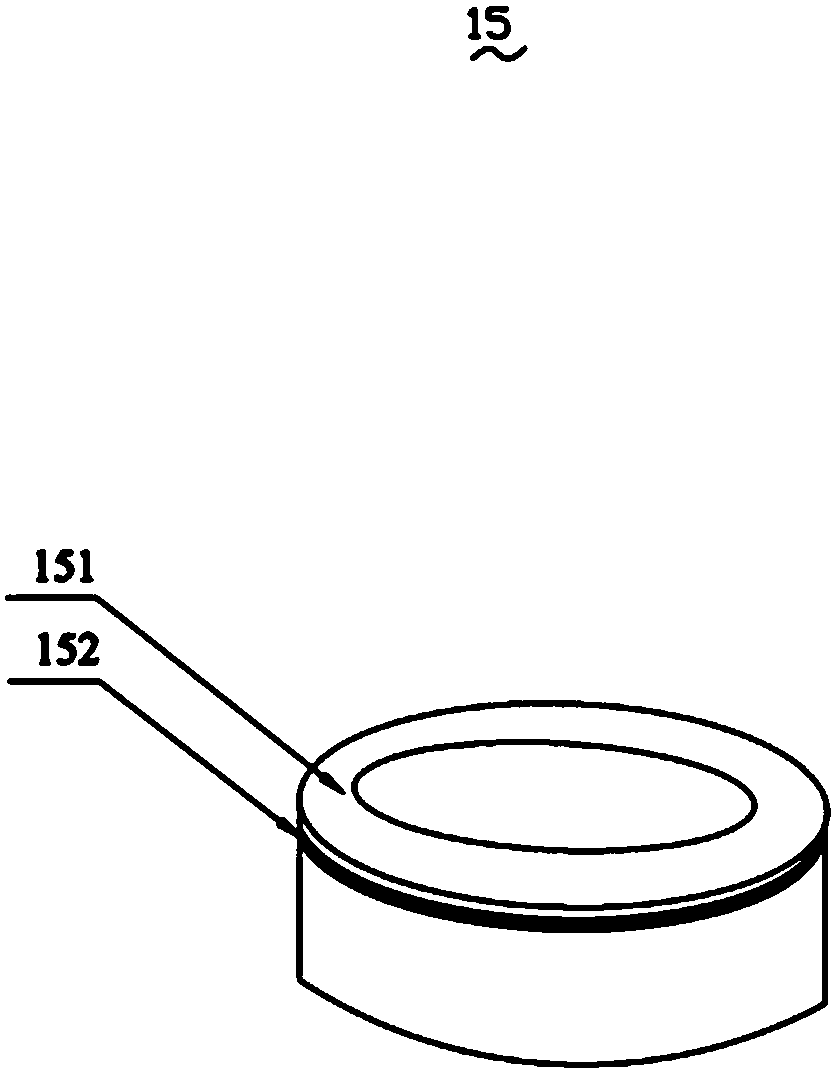

[0026] In the first embodiment of the present invention, a device for collecting heat dissipation water vapor at the top of a thermal power plant circulating water cooling tower includes a collection cover 14, a diversion groove 15, four drain pipes 16, a rigid ring 12 and a plurality of axial flow fans 13. The collection cover 14 is an annular cover body, its annular side is in a certain radian, and it is located at the top of the cooling tower. The guide groove 15 is an annular body, which surrounds the upper part of the cooling tower and is located at the bottom of the collection cover 14 and is integrated with it. The four drain pipes 16 are located on the side wall of the cooling tower, and one end of each drain pipe 16 is communicated with the diversion groove 15, and the other end is connected with the cold water pool 115. The height of the upper surface of the diversion groove 15 from the tower top 111 is h, and the height of the lower surface of the diversion groove 15...

no. 2 example

[0030] In the second embodiment of the present invention, a method 2 of collecting heat dissipation water vapor at the top of a thermal power plant circulating water cooling tower (for the structure mentioned in the following steps, please refer to the view and numbering of the device provided in the first embodiment of the present invention) comprises the following steps:

[0031] Step S1: Install the rigid ring 12, the axial flow fan 13, the collection cover 14, the diversion groove 15 and the drain pipe 16 on the top of the cooling tower 11. During installation, according to the temperature sensor and the pressure sensor at the top 111 of the cooling tower 11 According to the heat dissipation and load-bearing conditions, the axial fan 13 with different powers is selected.

[0032] Step S2: Sensing the local perennial wind direction, wind force, temperature and humidity of the cooling tower 11 and sending the signal to the CPU to adjust the shape of the collection cover 14 it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com