Water optimization system and method for wet flue gas desulfurization device with high-efficienty dust removal in thermal power plant

A wet flue gas desulfurization and thermal power plant technology, applied in chemical instruments and methods, separation methods, electrostatic effect separation, etc., can solve the problems of high quality and low use of water, high renovation costs, and inability to make full use of reuse water in power plants. , to achieve the effect of improving water reuse rate and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

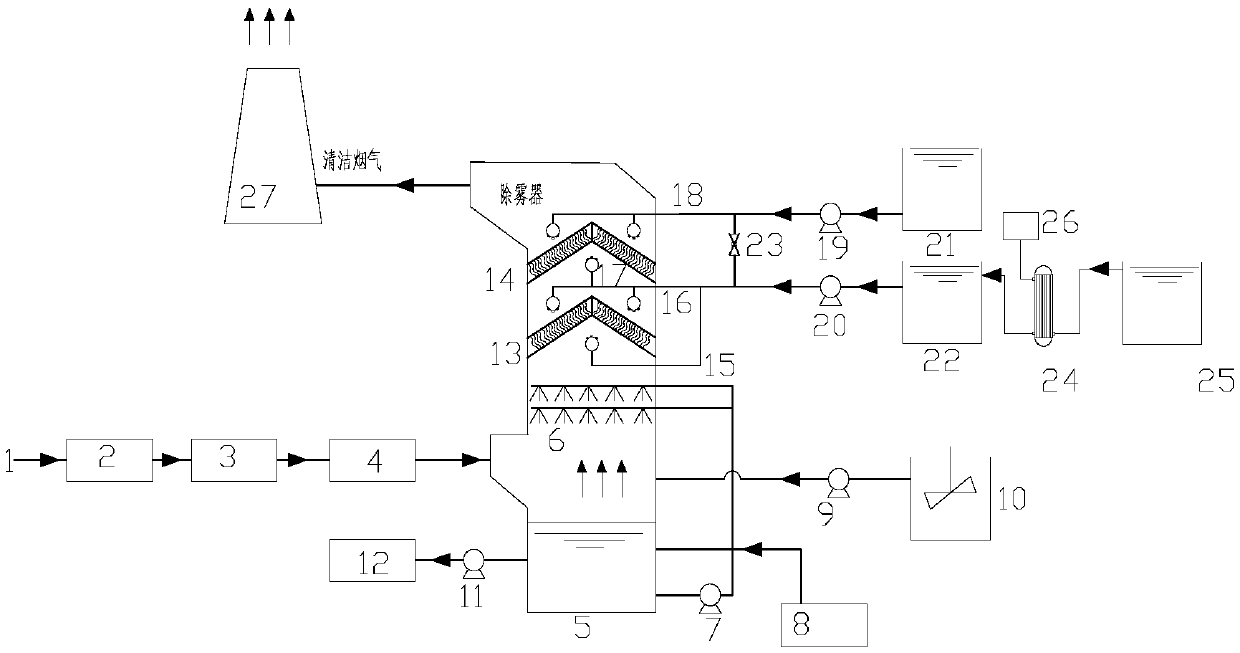

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] refer to figure 1 , the water optimization system for the wet flue gas desulfurization device of the thermal power plant with high efficiency dust removal according to the present invention includes a boiler outlet flue gas pipeline 1, a desulfurization absorption tower 5, a reuse water system, a desulfurization industrial water system, an oxidation fan 8 and a chimney 27 The flue gas pipe 1 at the boiler outlet is connected with the flue gas inlet of the desulfurization absorption tower 5, and the desulfurization absorption tower 5 is provided with a spray layer 6, a first layer of flushing water pipe 15, and a first layer of roof type demisting in sequence from bottom to top. device 13, the second layer of flushing water pipe 16, the third layer of flushing water pipe 17, the second layer of ridge type demister 14 and the fourth layer of flushing water pipe 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com