Antistatic finishing agent for fabric finishing

An antistatic finishing agent and fabric technology, applied in the field of fabrics, can solve the problems of poor comfort, hard hand feeling, hot and airtight wearing, etc., and achieve the effect of non-corrosiveness and improved antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

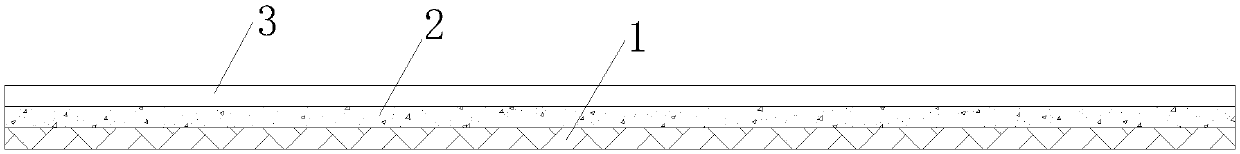

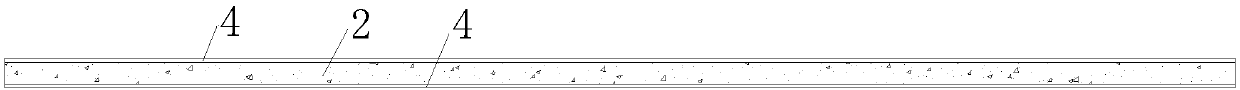

[0017] as attached figure 1 , 2 As shown, an antistatic degradable fabric, the fabric includes a bottom layer 1, a middle layer 2, and an upper layer 3 sequentially compounded;

[0018] The bottom layer 1 is made of conductive fiber, bamboo charcoal fiber and polyester fiber in a ratio of 1:1:1;

[0019] The middle layer 2 is woven from polyester fiber, and the flame-retardant fiber is made of the following raw materials in parts by weight: 44 parts of polysuccinic acid-co-butylene terephthalate, 24 parts of ethylene butyl acrylate copolymer, poly 6 parts of vinyl chloride grafted maleic anhydride, 14 parts of glass fiber, 2 parts of gelatin, 6.5 parts of soybean protein fiber, 47 parts of maleic anhydride, 9 parts of fumed silica, 1.3 parts of tributyl citrate, 5.2 parts of cellulose acetate part, 0.6 part of perchlorocyclopentane, all raw materials are mixed and heated into a molten state, and then extruded polyester fibers from the spinneret;

[0020] The upper layer 3 i...

Embodiment 2

[0031] as attached figure 1 , 2 As shown, an antistatic degradable fabric, the fabric includes a bottom layer 1, a middle layer 2, and an upper layer 3 sequentially compounded;

[0032] The bottom layer 1 is made of conductive fiber, bamboo charcoal fiber and polyester fiber in a ratio of 1:1:1;

[0033] The middle layer 2 is woven from polyester fiber, and the flame-retardant fiber is made of the following raw materials in parts by weight: 44 parts of polysuccinic acid-co-butylene terephthalate, 24 parts of ethylene butyl acrylate copolymer, poly 6 parts of vinyl chloride grafted maleic anhydride, 14 parts of glass fiber, 2 parts of gelatin, 6.5 parts of soybean protein fiber, 47 parts of maleic anhydride, 9 parts of fumed silica, 1.3 parts of tributyl citrate, 5.2 parts of cellulose acetate part, 0.6 part of perchlorocyclopentane, all raw materials are mixed and heated into a molten state, and then extruded polyester fibers from the spinneret;

[0034] The upper layer 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com