Sphingomonas azotifigens and application in preparation of gellan gum

The technology of sphingomonas and gellan gum is applied to nitrogen-fixing sphingomonas and the application field in the preparation of gellan gum, and can solve the problems of yellow color of fermentation product, high production cost, and specification of gellan gum. less problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

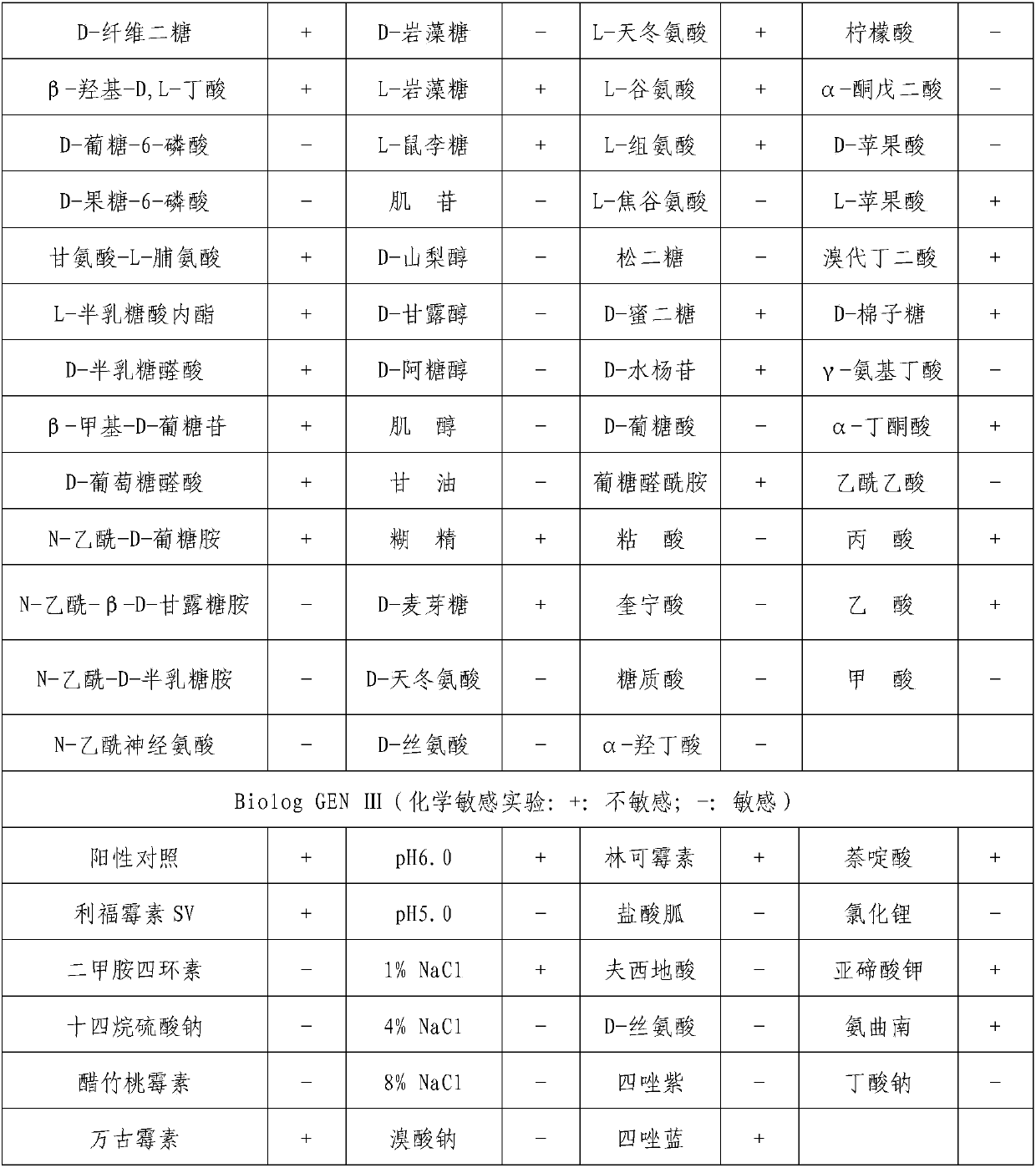

Image

Examples

Embodiment 1

[0066] The strains in this example are as described above.

[0067] Apply the nitrogen-fixing sphingomonas Sphingomonas azotifigens CGMCC No.14239 to adopt the following process steps when preparing gellan gum:

[0068] A. Inoculate Sphingomonas azotifigens CGMCC No.14239 into a fermentation medium containing carbon source, nitrogen source and necessary nutrients after sterilization;

[0069] B, control the pH and temperature of the fermentation medium, carry out aerated fermentation to prepare fermented liquid;

[0070] C. When the viscosity of the fermentation broth no longer increases or the fermentation period is less than or equal to 50 hours, the fermentation ends;

[0071] D, carry out post-extraction to the fermented liquid made in step C to make gellan gum.

[0072] Since the above-mentioned post-extraction step belongs to the existing conventional technology, the applicant will not repeat the process and process parameters involved here.

[0073] The temperature c...

Embodiment 2

[0095] Fermentation medium in steps A and B is made up of the following raw materials of mass percentage:

[0096] Sucrose 3.5%; fish peptone 0.2%; dipotassium hydrogen phosphate 0.15%; potassium dihydrogen phosphate 0.2%; anhydrous magnesium sulfate 0.08%; the balance is sterile water; pH=7.5-8.0.

[0097] In the described step A, after expanding the cultivation of Sphingomonas azotifigens CGMCCNo.14239, the seed liquid is inoculated in the sterilized fermentation medium according to the seed liquid: fermentation medium=12% inoculation amount .

[0098] The aerated fermentation process conditions in the step B are as follows:

[0099] Within 10 hours: temperature 36°C, pressure 0.05MPa, pH=7.0-7.5, ventilation volume 0.3vvm;

[0100] 11-20 hours: temperature 36°C, pressure 0.05MPa, pH=7.0-7.5, ventilation volume 0.4vvm;

[0101] 21-30 hours: temperature 36°C, pressure 0.05MPa, pH=7.0-7.5, ventilation rate 0.5vvm; 21-25 hours, add sterile water with a mass percentage of 1.0...

Embodiment 3

[0111] Fermentation medium in steps A and B is made up of the following raw materials of mass percentage:

[0112] Sucrose 3.2%; fish peptone 0.15%; dipotassium hydrogen phosphate 0.13%; potassium dihydrogen phosphate 0.15%; anhydrous magnesium sulfate 0.07%; the balance is sterile water; pH=7.5-8.0.

[0113] In the step A, after expanding the cultivation of Sphingomonas azotifigens CGMCCNo.14239, the seed liquid is inoculated in the sterilized fermentation medium according to the seed liquid: fermentation medium=10% inoculation amount .

[0114] The aerated fermentation process conditions in the step B are as follows:

[0115] Within 10 hours: temperature 34°C, pressure 0.04MPa, pH=7.0-7.5, ventilation volume 0.25vvm;

[0116] 11-20 hours: temperature 34°C, pressure 0.04MPa, pH=7.0-7.5, ventilation volume 0.35vvm;

[0117] 21-30 hours: temperature 34°C, pressure 0.04MPa, pH=7.0-7.5, ventilation rate 0.45vvm; 21-25 hours, add sterile water with a mass percentage of 1.0%-1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com