Preparation method for hollow titanium dioxide @ silicon dioxide/water-based polyurethane composite transparent and thermal insulation coating

A water-based polyurethane and titanium dioxide technology, applied in polyurea/polyurethane coatings, titanium oxide/hydroxide, titanium dioxide, etc., can solve problems such as low visible light transmittance, low infrared rejection rate, and poor thermal insulation performance. Achieve the effect of realizing particle size and wall thickness, reducing photocatalytic performance, and improving heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

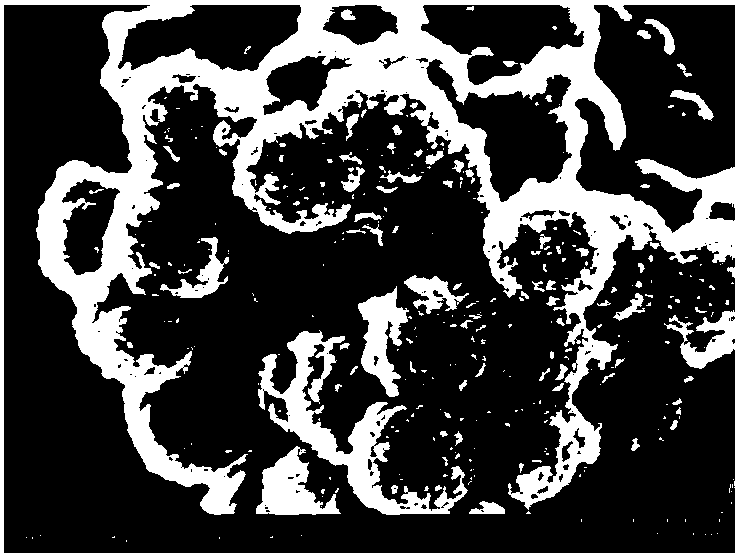

Image

Examples

Embodiment 1

[0038] (1) Add 5g of cationic polystyrene emulsion and 1.19g of ammonia water with a volume concentration of 25% into a three-necked flask containing 80mL of absolute ethanol and mix uniformly to obtain a mixed solution; then 0.5g of tetrabutyl titanate and Add 0.149g of triethanolamine to 1mL of absolute ethanol and mix evenly, and dropwise add it into the mixed solution with a dropper. The dropping time is 1h. After the dropping is completed, react at 50°C for 0.5h, and the product is centrifuged and washed with absolute ethanol. Obtain polystyrene@titanium dioxide particles. Disperse the particles obtained above in 80mL of isopropanol and 5mL of deionized water, adjust the pH to 2.5 with acetic acid, then add 0.1g of tetraethyl orthosilicate, react at 50°C for 2h, and centrifuge the product with isopropanol, 500 ℃ for 5 hours to obtain hollow titania@silica microspheres. Wherein, the particle diameter of the latex particles of the cationic polystyrene emulsion is 20 nm.

...

Embodiment 2

[0041](1) 7g of cationic polystyrene emulsion and 2.38g of ammonia water with a volume concentration of 25% are added to a three-necked flask containing 90mL of absolute ethanol and mixed uniformly to obtain a mixed solution; then 0.9g of tetrabutyl titanate and Add 0.218g of triethanolamine to 2mL of absolute ethanol and mix evenly, and add dropwise to the mixed solution with a dropper. The dropping time is 1h. After the dropping is completed, react at 60°C for 1h, and the product is centrifuged and washed with absolute ethanol to obtain Polystyrene@TiO2 particles. Disperse the particles obtained above in 90mL of isopropanol and 8mL of deionized water, adjust the pH to 3.0 with acetic acid, then add 0.15g of tetraethyl orthosilicate, react at 60°C for 3h, and centrifuge the product with isopropanol, 550 ℃ calcination for 4.5h to obtain hollow titania@silica microspheres. Wherein, the particle diameter of the latex particles of the cationic polystyrene emulsion is 150 nm.

...

Embodiment 3

[0044] (1) 9g of cationic polystyrene emulsion and 4.76g of ammonia water with a volume concentration of 25% were added to a three-necked flask containing 100mL of absolute ethanol and mixed uniformly to obtain a mixed solution; then 1.2g of tetrabutyl titanate and Add 0.596g of triethanolamine to 3mL of absolute ethanol and mix evenly, and dropwise add it into the mixed solution with a dropper. The dropping time is 1.5h. After the dropping is completed, react at 70°C for 4h, and the product is centrifuged and washed with absolute ethanol. Obtain polystyrene@titanium dioxide particles. Disperse the above obtained product in 100mL isopropanol and 10mL deionized water, adjust the pH to 3.5 with acetic acid, then add 0.2g tetraethyl orthosilicate, react at 70°C for 4h, wash the product with isopropanol by centrifugation, 600°C Calcined for 4 hours to obtain hollow titania@silica microspheres. Wherein, the particle diameter of the latex particles of the cationic polystyrene emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com