Graphene transfer and doping method

A graphene and dopant technology, applied in the field of graphene, can solve the problems of poor adhesion, unstable doping, and inability to achieve large-scale and high-quality graphene transfer, and achieves good adhesion and is not easy to fall off. , to avoid the effect of damage to the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

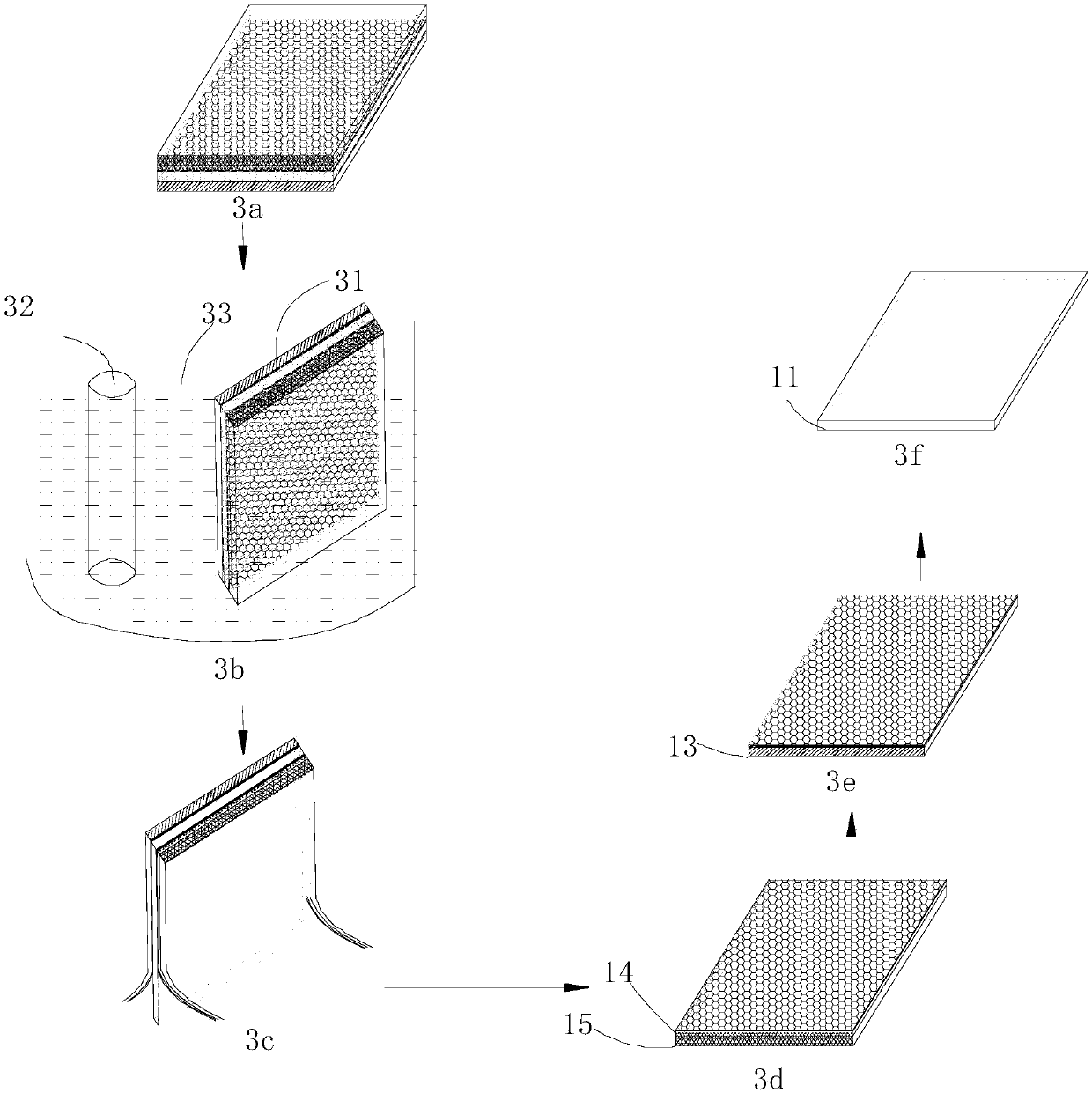

[0024] Graphene is deposited on the copper sheet by chemical vapor deposition. Graphene grows on both sides of the copper sheet; a silicone adhesive film is attached to the graphene on one side of the copper sheet to ensure the flatness of the copper sheet, which is beneficial to the subsequent target substrate and adhesive layer. fit; the FeCl 3 Mix with viscosity regulator, photocuring agent, and hydroxyethyl enoate mixture at a mass ratio of 1:10, and ultrasonically 20min at room temperature to make it fully and uniformly mixed; coat a 25um thick ultrasonic mixture on a 200um target substrate ; Lay the target substrate coated with the adhesive layer with the graphene on the other side of the copper sheet; use a 500w UV light source to irradiate the adhesive layer on the target substrate surface for 3 minutes, so that the adhesive layer is completely cured;

[0025]The electrolyte is prepared, wherein the concentration of NaOH is 2M, and the concentration of CTAB (cetyltrime...

Embodiment 2

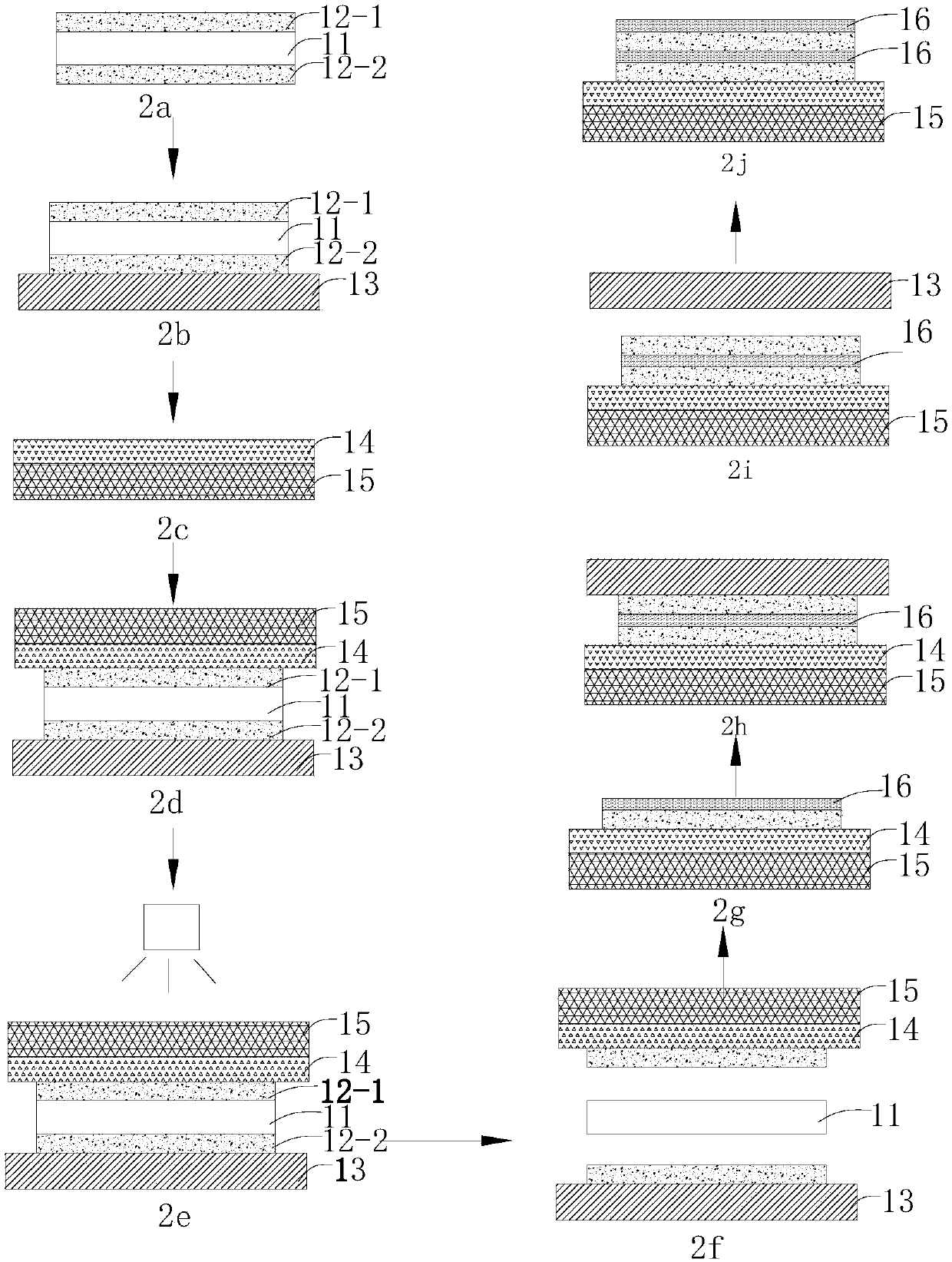

[0028] Such as figure 1 Graphene is grown on one side 11 of the substrate; the side 12-2 with the graphene grown on the substrate is attached to the transition substrate 13; on the target substrate 15, the adhesive layer 14 with doping is coated; graphite will be grown The other side 12-1 of the substrate is attached to the target substrate 15 coated with the dopant glue layer 14; the dopant and the glue are mixed according to the weight ratio of 1:10 to 1:30; at room temperature Ultrasound for 20-30 minutes under the condition to fully dissolve the dopant and glue; coat the target substrate 15 with a uniform thickness of 5-50 μm and the dissolved liquid of the dopant and glue; put the target substrate 15 under 500-1000W ultraviolet light Irradiate for 1-3 minutes; cure the adhesive layer 14 with a UV light source; completely peel off the substrate 11 and graphene by the bubble stripping method, and obtain the target substrate 15, substrate 11, and graphene-attached adhesive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com