Preparation method of cadmium sulfide-molybdenum sulfide-tungsten sulfide heterojunction photocatalytic composite material with urchin-like structure and application of cadmium sulfide-molybdenum sulfide-tungsten sulfide heterojunction photocatalytic composite material

A composite material and sea urchin-like technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of activity decline, low activity of hydrogen production by photo-splitting water, and achieve good application prospects and industrialization potential. The effect of excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

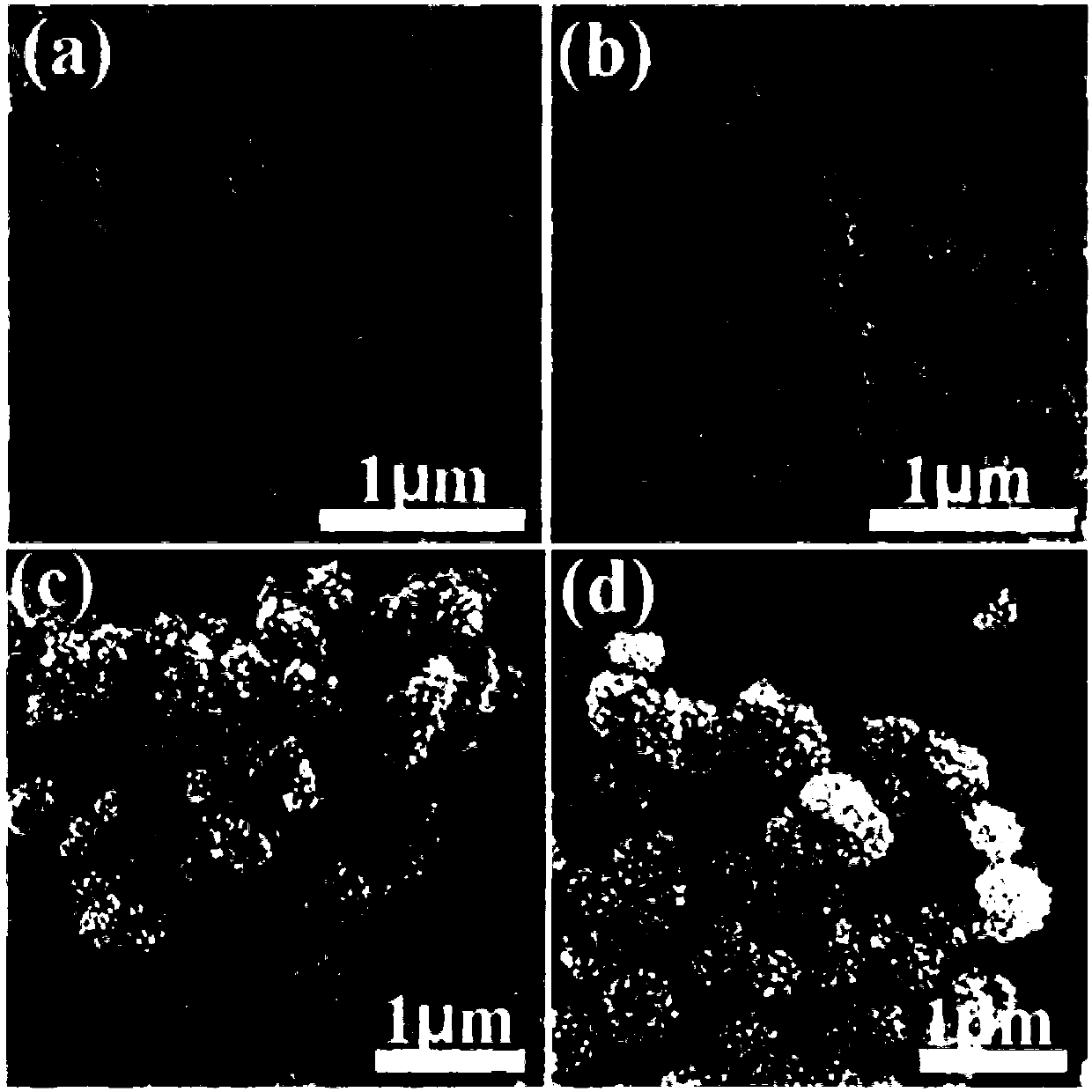

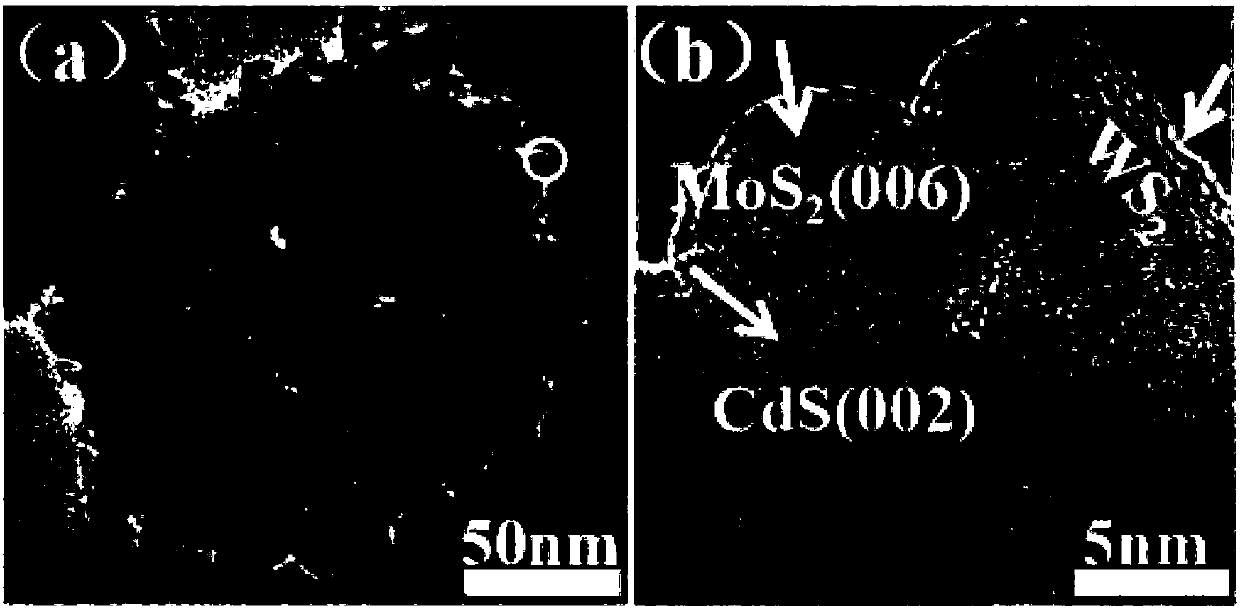

Image

Examples

Embodiment 1

[0046] S1: To an appropriate amount of organic solvent ethylene glycol, add cadmium diethyldithiocarbamate (CED), molybdenum diethyldithiocarbamate (Mo(dedc) 5 ) and tungsten diethyldithiocarbamate (W(dedc) 6 ), fully stir with a magnetic stirrer, mix evenly, and obtain the precursor reaction solution;

[0047] S2: The precursor reaction solution is subjected to a two-stage microwave heating constant temperature reaction to obtain a cadmium sulfide-molybdenum sulfide-tungsten sulfide heterojunction photocatalytic composite material, specifically:

[0048] S2-1: under the microwave power of 200W, heat the precursor reaction solution obtained in step S1 from room temperature to 90°C, and keep at this temperature for 10 minutes to obtain the first reaction solution;

[0049] S2-2: Continue heating the first reaction solution to 160°C under a microwave power of 500W, and keep it at this temperature for 10 minutes to obtain a second reaction solution;

[0050] S2-3: naturally coo...

Embodiment 2-5

[0051] Embodiment 2-5: the investigation of raw material consumption ratio

[0052] In addition to using different mass ratios of cadmium diethyldithiocarbamate (CED) and molybdenum diethyldithiocarbamate (Mo(dedc) 5 ) and tungsten diethyldithiocarbamate (W(dedc) 6 ) except that other operations are the same as in Example 1, so that Embodiment 2-5 has been carried out, and the used raw material consumption ratio and composite material nomenclature are shown in Table 1 below.

[0053] Table 1. Composite materials prepared under different raw material dosage ratios

[0054]

Embodiment 6-9

[0055] Example 6-9: Investigation of the end temperature of two-stage microwave heating

[0056] Embodiment 6-9: Except using the endpoint temperature shown in the following table 3 in step S3-3, other operation is all the same as embodiment 1, thereby carried out embodiment 6-9, the endpoint used and composite material nomenclature see Table 3 below.

[0057] Table 3. Composites prepared at different endpoint temperatures

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com