Polyamide compound for environment-friendly electroplating and preparation method thereof

A technology of aromatic ring polyamide and polyamide, which is applied in the field of polyamide composites for environmental protection electroplating and its preparation, and can solve problems such as allergies, inability to meet the adhesion requirements of metal electroplating products, and low bonding strength of substrate electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

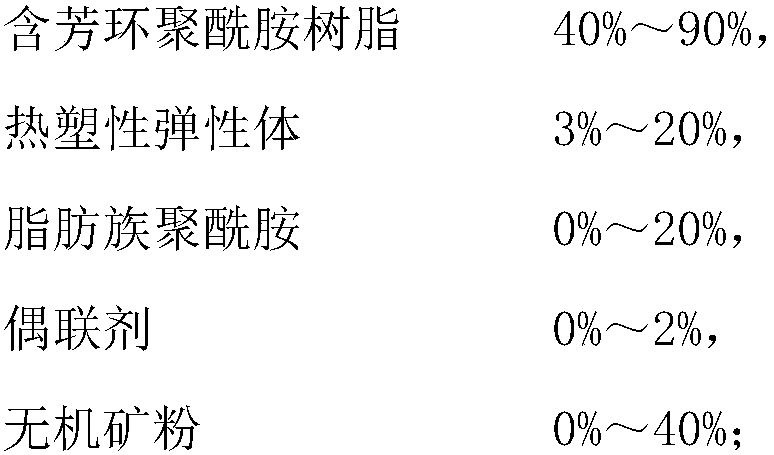

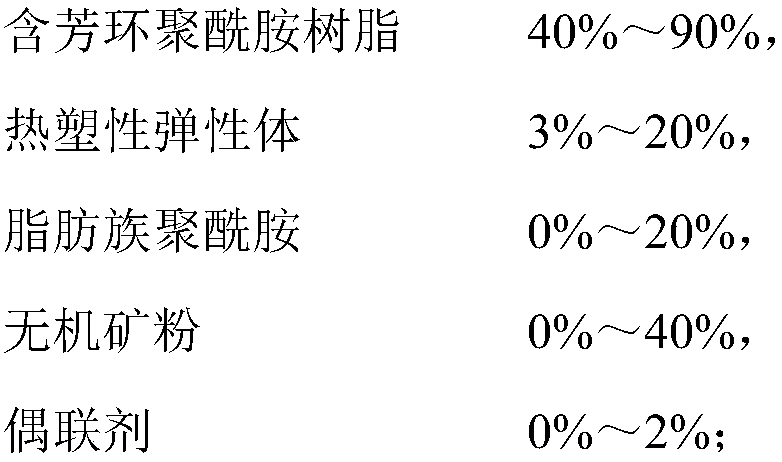

Method used

Image

Examples

Embodiment 1

[0088] A kind of polyamide compound that is used for environment-friendly electroplating, comprises following raw material (raw material total weight 10KG) by weight percentage:

[0089] PA6T / 66 90%,

[0090] TPE 10%.

[0091]The above-mentioned preparation method for the polyamide compound of environmental protection electroplating, comprises the following steps:

[0092] Adding PA6T / 66 and TPE into a twin-screw extruder through a main feeder for melt polymerization, and strand cutting to obtain the polyamide compound of the present invention.

Embodiment 2

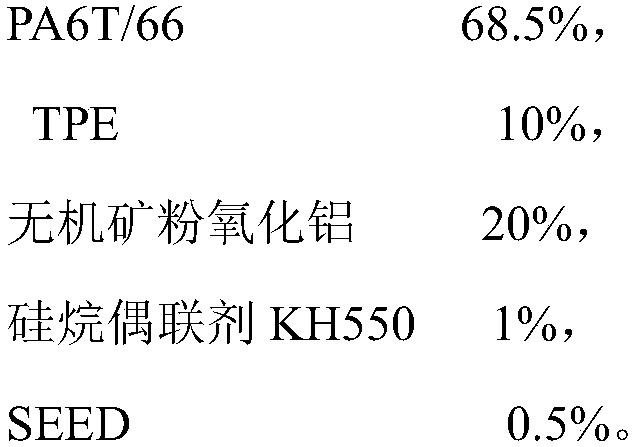

[0094] A kind of polyamide compound that is used for environment-friendly electroplating, comprises following raw material (raw material total weight 10KG) by weight percentage:

[0095]

[0096] The above-mentioned preparation method for the polyamide compound of environmental protection electroplating, comprises the following steps:

[0097] (1) Add PA6T / 66 and TPE to the twin-screw extruder through the main feeder to carry out melt polymerization, and pelletize the strands to obtain the blend, which is set aside;

[0098] (2) Add inorganic mineral powdered alumina into the high mixer, raise the temperature of inorganic mineral powdered alumina to 120°C, then add silane coupling agent KH550 for reaction, the reaction time is 30 minutes, take it out for use;

[0099] (3) The blend that step (1) obtains and SEED are joined in the twin-screw extruder by main feeder, and the inorganic ore powder aluminum oxide that is processed through step (2) is added in side feeder simulta...

Embodiment 3

[0101] A kind of polyamide compound that is used for environment-friendly electroplating, comprises following raw material (raw material total weight 10KG) by weight percentage:

[0102]

[0103] The above-mentioned preparation method for the polyamide compound of environmental protection electroplating, comprises the following steps:

[0104] (1) PA12T and TPO are added to the twin-screw extruder through the main feeder to carry out melt polymerization, and the strands are pelletized to obtain the blend, which is set aside;

[0105] (2) Add inorganic mineral powdered alumina into the high mixer, raise the temperature of inorganic mineral powdered alumina to 120°C, then add silane coupling agent KH550 for reaction, the reaction time is 30 minutes, take it out for use;

[0106] (3) The blend that step (1) obtains and SEED are joined in the twin-screw extruder by main feeder, add the inorganic mineral powder alumina and the processing through step (2) in side feeder simultane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com