Manufacturing equipment for veneer-plastic composite floor

A technology for composite flooring and manufacturing equipment, which is applied in the jointing of wooden veneers, manufacturing tools, building construction, etc., and can solve problems such as time-consuming and energy-consuming, stress concentration, and uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

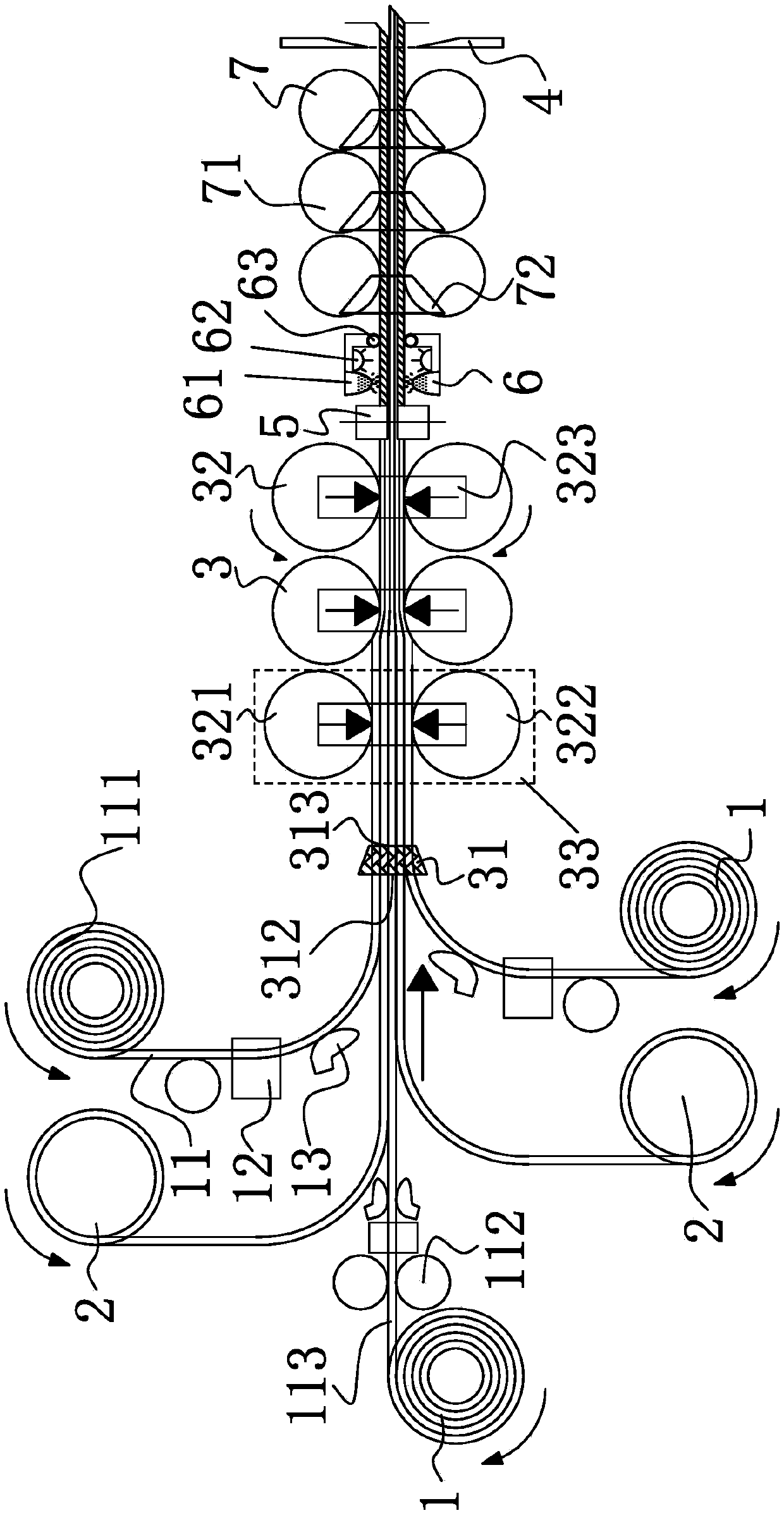

[0020] Specific Embodiment 1: Combining figure 1 Describe this embodiment, a kind of veneer-plastic composite flooring manufacturing equipment, has veneer supply device 1, also has plastic film supply device 2, heating rolling device 3, milling device 5, rolling cold pressing device 7 and cutting Device 4, the veneer supply device 1 has a veneer conveying component 11, a veneer pretreatment component 12 and a coupling agent coating component 13, and the veneer conveying component 11, veneer pretreatment component 12 and coupling agent The coating assembly 13 is sequentially connected; the heating rolling device 3 has an inlet end and an outlet end, and the veneer supply device 1 and the plastic film supply device 2 are all connected to the inlet end of the heating rolling device 3; The outlet end of rolling device 3 is connected with milling device 5, and described milling device 5 is connected with rolling cold pressing device 7, and comprises cold pressing assembly 71 and sp...

specific Embodiment approach 2

[0022] Specific Embodiment 2: Combining figure 1 Describe this embodiment, the manufacturing equipment of veneer-plastic composite flooring in this embodiment, there is also a paint film device 6 between the heating and rolling device 3 and the cutting device 4, the paint film The device 6 has a painting assembly 61, an ultraviolet light curing assembly 62 and a sanding assembly 63, and the painting assembly 61, an ultraviolet light curing assembly 62 and a sanding assembly 63 are connected in sequence, and the painting assembly 61, the ultraviolet light curing assembly 62 and There are a plurality of sanding components 63; others are the same as in Embodiment 1.

[0023] The technical effect of this embodiment is: the equipment can make the floor surface quickly generate a high-quality paint film with stable performance, and because the paint film device is arranged after the heating and rolling device, it is more conducive to the paint film to absorb heat and solidify quickl...

specific Embodiment approach 3

[0024] Embodiment 3: Combining figure 1 and figure 2 Describe this embodiment, the veneer-plastic composite flooring manufacturing equipment described in this embodiment, the veneer conveying assembly 11 has a veneer shelving part 111, a veneer trimming machine 112 and a veneer conveyor belt 113, the The veneer conveying belt 113 is connected to the veneer shelving part 111 and the veneer trimming machine 112; the other is the same as the specific embodiment 1 or 2.

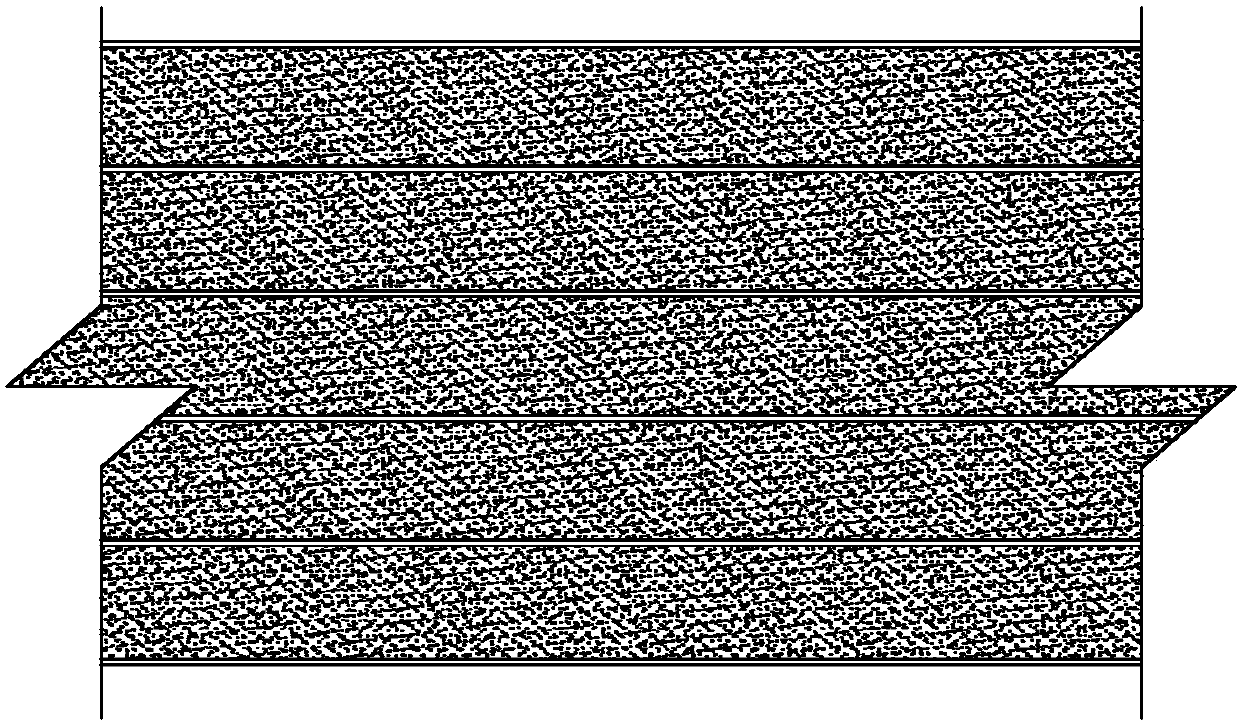

[0025] The technical effect of this embodiment is: after the veneer is trimmed, not only can it be more tidy, but the quality of the floor is improved, and processing difficulties that may occur in subsequent processing are avoided. The veneer can be divided into neat parts before it enters the heating and rolling device for billet assembly, and then it is possible to manufacture veneer-plastic film composite panels with narrow width and discontinuous veneer in the width direction. According to needs, it can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com