Manganese monoxide/graphene composite material used as negative electrode of lithium ion battery and preparation method of composite material

A lithium-ion battery and manganese monoxide technology, which is applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of undisclosed electrochemical performance and high cost, and achieve uniform shape and size, low cost, and ionic The effect of short diffusion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Dissolve 1.5mmol manganese acetate and 0.1g polyvinylpyrrolidone in 50mL ethylene glycol solvent to obtain a mixed solution;

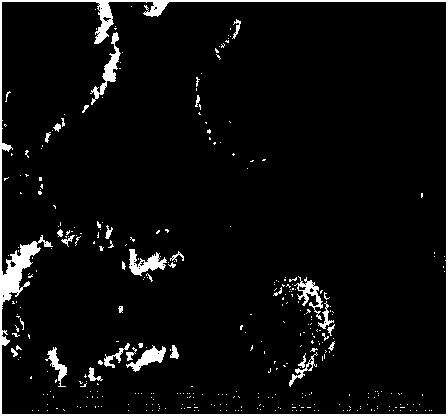

[0051] (2) The mixed solution obtained in step (1) was refluxed at 170°C for 6 hours, cooled to room temperature naturally, centrifuged at 8000r / min for 8 minutes, washed with ethanol for 4 times, and then placed at 80°C, Dry for 12 hours to obtain manganese alkoxide;

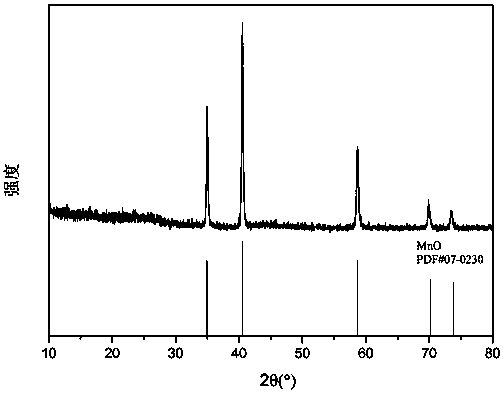

[0052] (3) The manganese alkoxide obtained in step (2) is heated from room temperature to 500 °C at a rate of 3 °C / min in an air atmosphere, calcined for 4 hours, and cooled to room temperature with the furnace to obtain a manganese monoxide precursor;

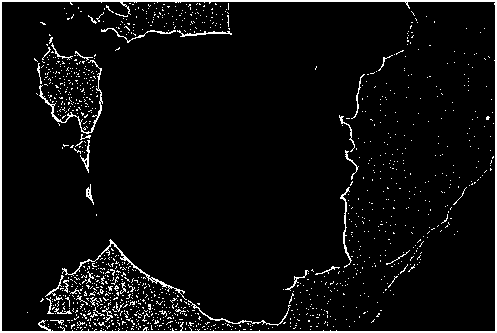

[0053] (4) Put 50 mg of the manganese monoxide precursor obtained in step (3) in 100 mL of graphene oxide aqueous solution with a mass concentration of 0.1 mg / mL, stir for 6 h, and freeze-dry for 48 h at -45 °C under a vacuum of 35 Pa to obtain black powder;

[0054] (5) Put 50 mg of the black powder obtained in step (4) in...

Embodiment 2

[0062] (1) Dissolve 4 mmol of manganese acetate and 0.3 g of cetyltrimethylammonium bromide in 100 mL of glycerol solvent to obtain a mixed solution;

[0063] (2) The mixed solution obtained in step (1) was refluxed at 160°C for 4 hours, cooled naturally to room temperature, centrifuged at 6000r / min for 8 minutes, washed with ethanol for 5 times, and then placed at 100°C, Dry for 8 hours to obtain manganese alkoxide;

[0064] (3) The manganese alkoxide obtained in step (2) is heated from room temperature to 600 °C at a rate of 1 °C / min in an air atmosphere, calcined for 5 hours, and cooled to room temperature with the furnace to obtain a manganese monoxide precursor;

[0065] (4) Put 50 mg of the manganese monoxide precursor obtained in step (3) in 100 mL of graphene oxide aqueous solution with a mass concentration of 0.05 mg / mL, stir for 8 h, and freeze-dry at -50 ° C and vacuum degree of 40 Pa for 40 h to obtain black powder;

[0066] (5) Put 50mg of the black powder obtai...

Embodiment 3

[0073] (1) Dissolve 7.5mmol manganese acetylacetonate and 0.45g polyvinylpyrrolidone in 150mL ethylene glycol solvent to obtain a mixed solution;

[0074] (2) The mixed solution obtained in step (1) was refluxed at 170°C for 5 hours, cooled naturally to room temperature, centrifuged at 6000r / min for 6 minutes, washed with ethanol for 4 times, and then dried at 80°C 12h, get manganese alkoxide;

[0075] (3) The manganese alkoxide obtained in step (2) is heated from room temperature to 500 °C at a rate of 5 °C / min in an air atmosphere, calcined for 4 hours, and cooled to room temperature with the furnace to obtain a manganese monoxide precursor;

[0076] (4) Put 50 mg of the manganese monoxide precursor obtained in step (3) in 100 mL of graphene oxide aqueous solution with a mass concentration of 0.1 mg / mL, stir for 6 h, and freeze-dry for 48 h at -45 °C under a vacuum of 35 Pa to obtain black powder;

[0077] (5) Put 50 mg of the black powder obtained in step (4) into a 20 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com