Integrated floor heating plate with high heat transferring efficiency

An efficient and integrated heat transfer technology, applied in buildings, building structures, floors, etc., can solve problems such as difficult maintenance, achieve standardized control, and flexible laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

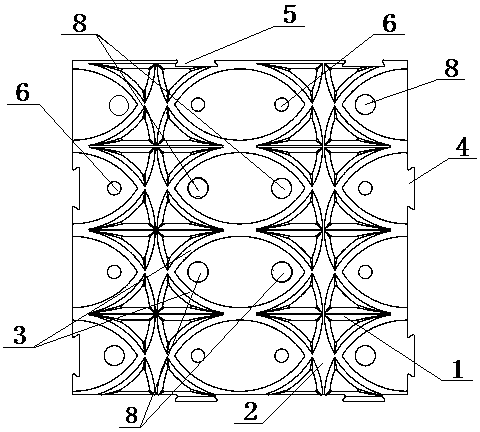

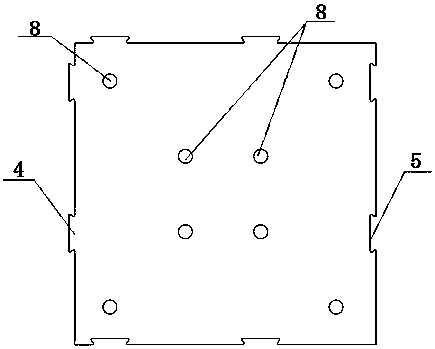

[0043] like figure 1 , figure 2 and image 3 As shown, an integrated floor heating panel with high heat transfer efficiency includes a heat-insulating bottom plate and a heat-transfer top plate used in conjunction with the heat-insulating bottom plate. At least two transverse grooves 1 and at least two longitudinal grooves 2 are formed on the upper surface of the heat-insulating bottom plate , two transverse grooves and two longitudinal grooves vertically intersect to form a unit cell, and the nodes where the transverse grooves and longitudinal grooves intersect are in a connected state; the upper surface of the heat-insulating bottom plate is also provided with an arc-shaped groove 3, and the Two arc-shaped grooves form a group, the opening direction is opposite, and they are arranged symmetrically in the unit cell. The point of tangency between the arc-shaped groove and the transverse groove is connected, and the lower surface of the heat transfer top plate is provided wi...

Embodiment 2

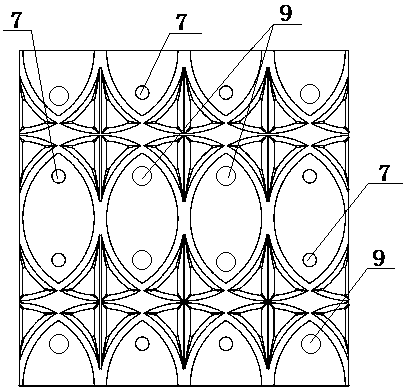

[0050] like Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, an integrated floor heating panel with high heat transfer efficiency includes a heat-insulating bottom plate and a heat-transfer top plate used in conjunction with the heat-insulating bottom plate. At least two transverse grooves and at least two longitudinal grooves are formed on the upper surface of the heat-insulating bottom plate. A horizontal groove and two vertical grooves vertically intersect to form a unit cell, and the intersection of the horizontal groove and the longitudinal groove is connected; Two pairs form a group with opposite opening directions and symmetrically arranged in the unit cell. The first and last ends of the arc-shaped groove are respectively connected with the longitudinal grooves on the left and right sides. The tangent points of the grooves and the transverse grooves are connected. The lower surface of the heat transfer top plate is provided with transverse grooves, longitudi...

Embodiment 3

[0057] The difference between this embodiment 3 and embodiment 1 is:

[0058] The raw materials and parts by weight used to prepare the heat transfer roof are: 90 parts of cement, 65 parts of medium sand, 90 parts of gravel, 20 parts of water, 25 parts of crystalline silica, 15 parts of granulated blast furnace slag powder, copper-plated steel 5 parts of fiber, the selection specification of cement is P.O52.5, the mesh size of crystalline silica is 100-200 mesh; the fiber width of copper-plated steel fiber is 0.15mm, the length is 5mm, and the tensile strength is 1000Mpa. The average particle size of sand is 0.25~0.5mm, the average particle size of gravel is 2~5mm, and the model of granulated blast furnace slag powder is S95.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com