Pretreatment method for thinning glass

A glass thinning and pretreatment technology, which is applied in the field of glass thinning, can solve the problems of strong corrosion of hydrofluoric acid, damage to glass substrates, and influence on production efficiency, and achieve the goal of improving yield rate, product quality, and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 1300L sulfuric acid into the closed liquid distribution tank, and prevent the volatilization of materials from affecting the working environment through the closed container. Weigh 11.14kg of nitric acid with an electronic scale, and use an electronic scale whose weighing unit can be accurate to two decimal places to ensure that the materials used are accurate. Add nitric acid into the sulfuric acid solution, then weigh 0.405 kg of ethylene glycol butyl ether with an electronic scale, add ethylene glycol butyl ether into the sulfuric acid solution; then weigh 27.36 kg of hydrochloric acid with an electronic scale, and add the hydrochloric acid into the sulfuric acid solution. After adding the material, heat the dosing tank. Make the temperature rise to 32° C., keep the temperature at this temperature, and then stir the above mixed solution for 30 minutes to make it evenly mixed to prepare the pretreatment solution.

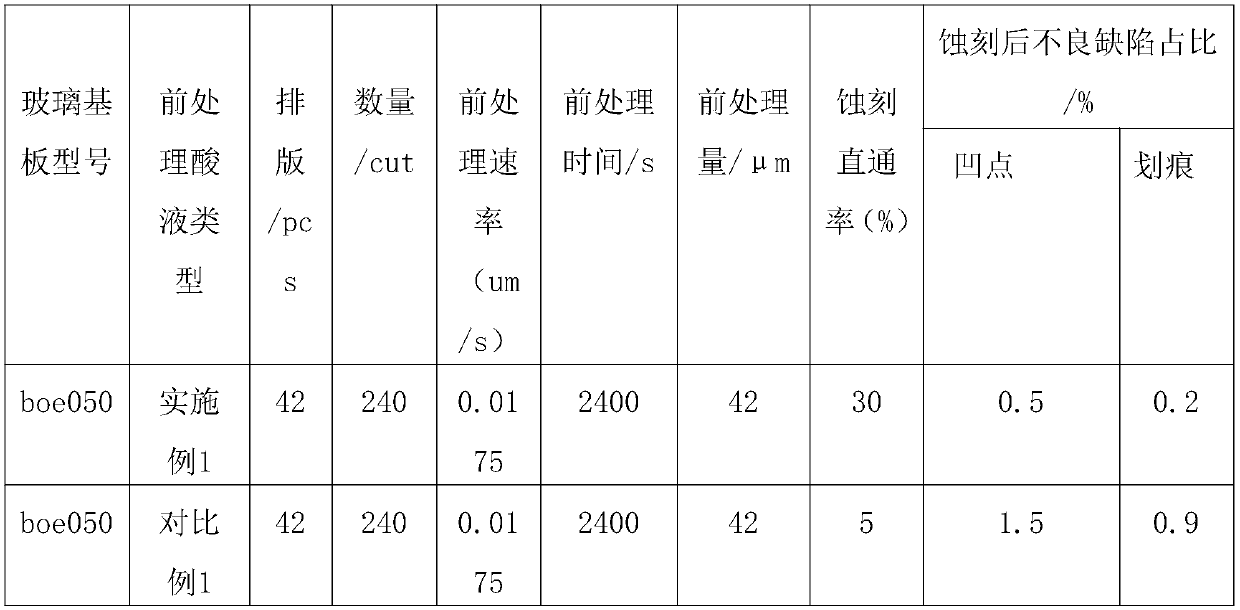

[0017] Take the TFT glass substrate of model boe...

Embodiment 2

[0019] Take the TFT glass substrate of model C050 produced by Longteng Electronics Co., Ltd. as the test sample. Using the pretreatment solution prepared in Example 1, 160 unthinned TFT glass substrates with a thickness of 1.0mm were placed in the basket, and then the basket was put into the solution tank for soaking. During soaking, use The laser thickness gauge monitors the thickness of the TFT glass substrate in real time, and its thinning thickness is 30 microns. During immersion, take out the dosing solution in the dosing tank, test the concentration of nitric acid by titration, and replenish nitric acid in time to ensure that the concentration does not change much. The soaking time is 2000s, and the reaction rate is 0.015μm / s. After the treatment, the basket was taken out, and the pits and scratches on the surface of the TFT glass substrate were observed. Among them, the glass substrate with obvious pits accounted for 0.01% of the total amount, and the glass substrate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com