Preparation method of nitrogen-rich sludge activated carbon doped with food leftover

A technology of sludge activated carbon and leftovers, which is applied in separation methods, chemical instruments and methods, carbon compounds, etc., can solve the problem that the specific surface area of sludge-based activated carbon is not high, the sludge activated carbon is not seen, and the output of sludge activated carbon is not high. It can improve the physical adsorption performance, enhance the chemical adsorption performance, and reduce the processing burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

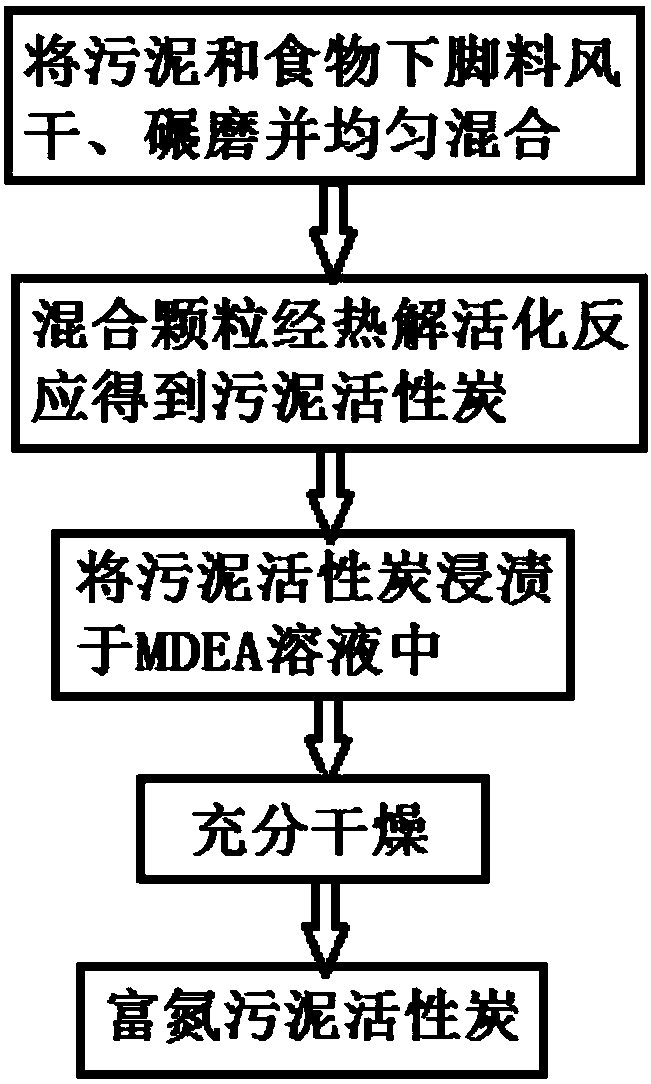

[0034] likefigure 1 As shown, it is the process flow diagram of the nitrogen-rich sludge activated carbon preparation method of the present invention, and its concrete steps are as follows:

[0035] (1) Air-dry the food scraps and sewage treatment plant sludge, and then grind the dried sludge and food scraps to obtain sludge particles and food scraps particles with a particle size of 30-90 meshes. According to the mass ratio of sludge to food scraps (1~3):1, mixed granules are prepared;

[0036] (2) The mixed particles obtained in step 1 are placed in a fixed bed for pyrolysis, the heating rate is 5 ℃ / min~20 ℃ / min, nitrogen is the protective gas, carbon dioxide is used as the activation gas, and the pyrolysis temperature is 400 ℃~600 ℃ ℃, after staying for 0.5h~2h, the sludge activated carbon mixed with food scraps was prepared;

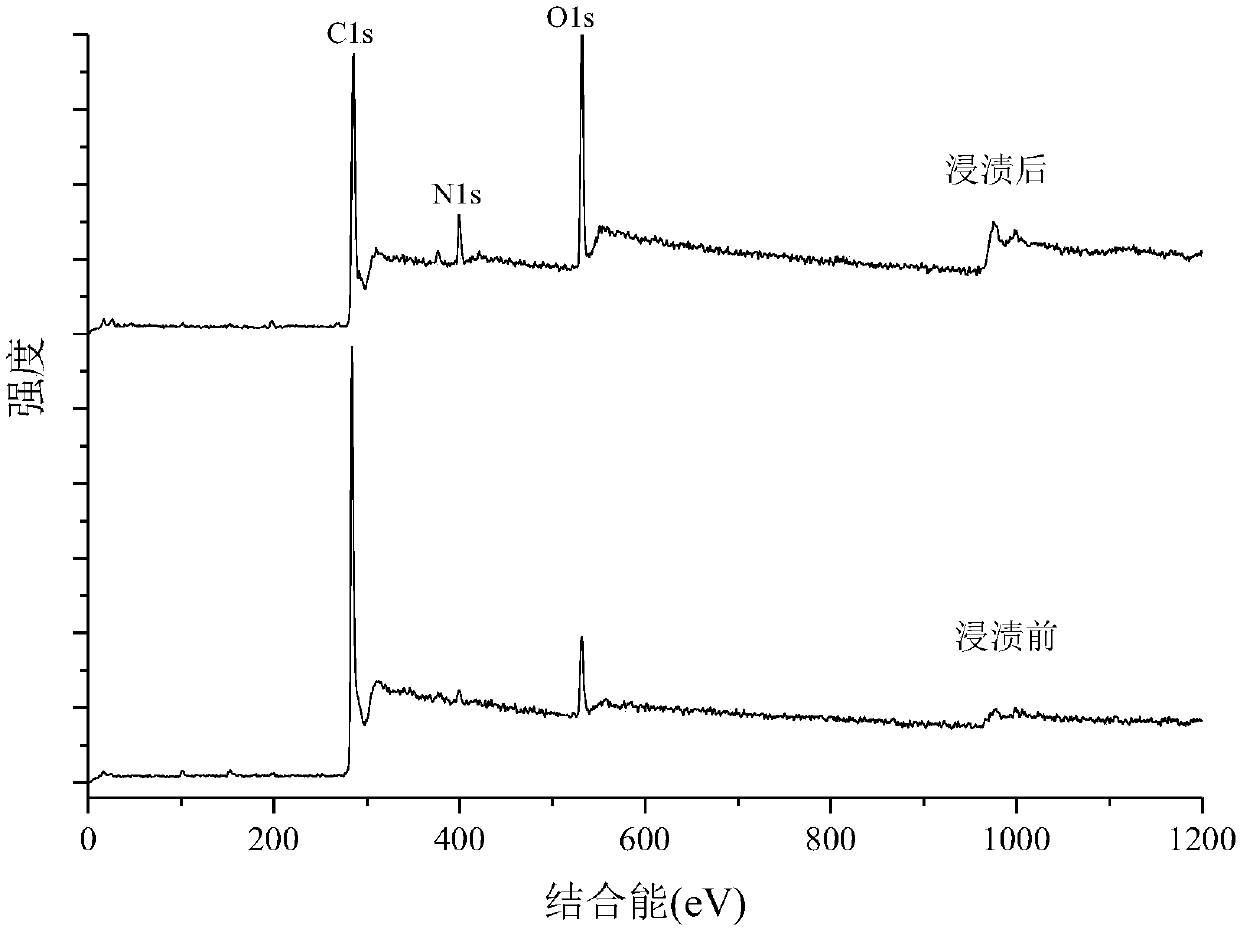

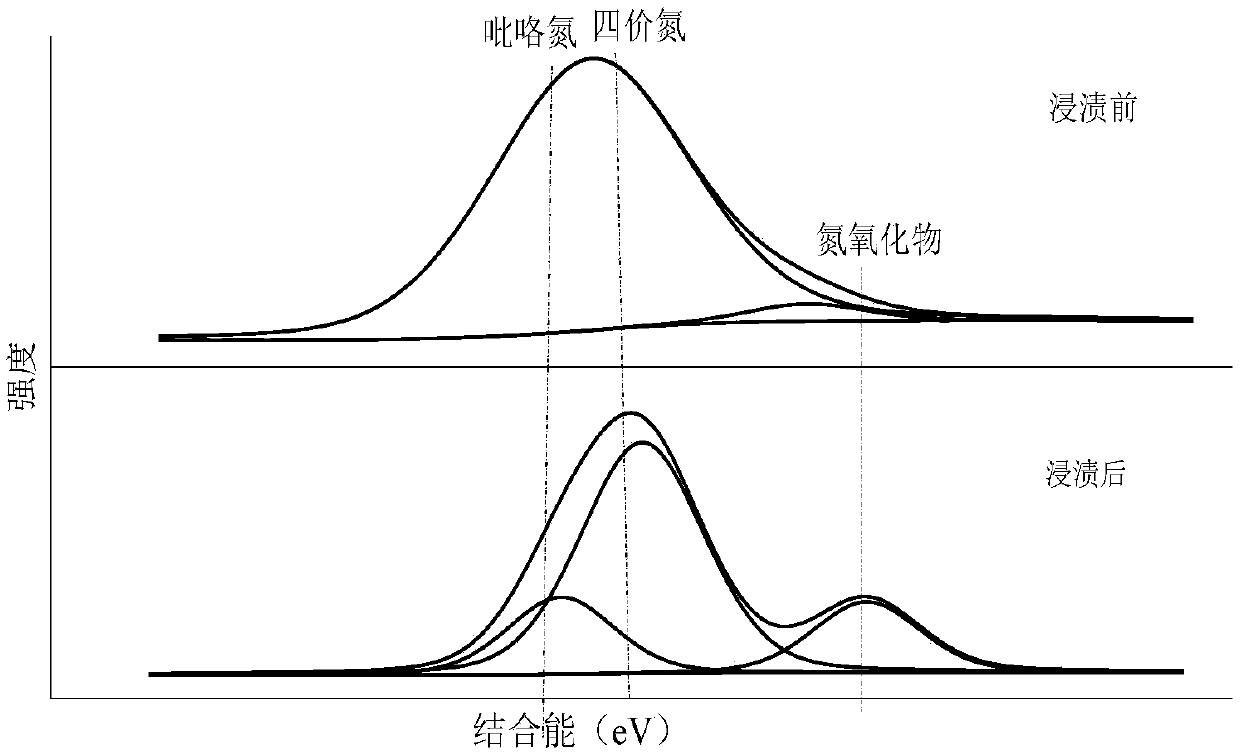

[0037] (3) Add MDEA to water to prepare 5-20wt% MDEA solution as the dipping solution, immerse the sludge activated carbon prepared in step 2 in th...

Embodiment 1

[0044] (1) Air-dry the food scraps from the canteen and the urban sewage plant sludge for 24 hours, respectively, and then grind the dried sludge and food scraps to obtain sludge particles and food scraps with a particle size of 30 meshes. . According to the mass ratio of sludge and food scraps to be 3:1, mixed granules are prepared.

[0045] (2) the mixed particles obtained in step 1 are placed in a fixed bed for pyrolysis, and the heating rate is 5°C / min. At the beginning, the nitrogen gas with a flow rate of 300mL / min is passed into the protective gas, and the carbon dioxide gas with a flow rate of 300mL / min is passed in. Activated, the pyrolysis temperature was 500 °C, and the sludge activated carbon mixed with food scraps was obtained after staying for 0.5 h.

[0046] (3) MDEA was mixed into deionized water to make 5wt% MDEA solution as immersion solution, then the sludge activated carbon obtained in step 2 was immersed in the above dipping solution, placed in a magnetic...

Embodiment 2

[0049] (1) Air-dry the food scraps from the canteen and the municipal sewage plant for 24 hours, respectively, and then grind the dried sludge and food scraps to obtain sludge particles and food scraps with a particle size of 60 meshes. . According to the mass ratio of sludge and food scraps to be 2:1, mixed granules are prepared.

[0050] (2) the mixed particles obtained in step 1 are placed in a fixed bed for pyrolysis, and the heating rate is 20° C. / min. At the beginning, the nitrogen gas with a flow rate of 400mL / min is introduced as a protective gas, and the carbon dioxide gas with a flow rate of 400mL / min is introduced. Activated, the pyrolysis temperature was 400 °C, and the sludge activated carbon mixed with food scraps was obtained by staying for 2 hours.

[0051] (3) MDEA was mixed into deionized water to make 20wt% MDEA solution as immersion solution, then the sludge activated carbon obtained in step 2 was immersed in the above dipping solution, placed in a magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com