Automobile lamp coating technology

A technology of automotive lamps and crafts, which is applied in metal material coating technology, household appliances, sputtering coating, etc., can solve the problems of uneven film thickness and low reflectivity of the film, and achieve stable reflectivity and good protection , the effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

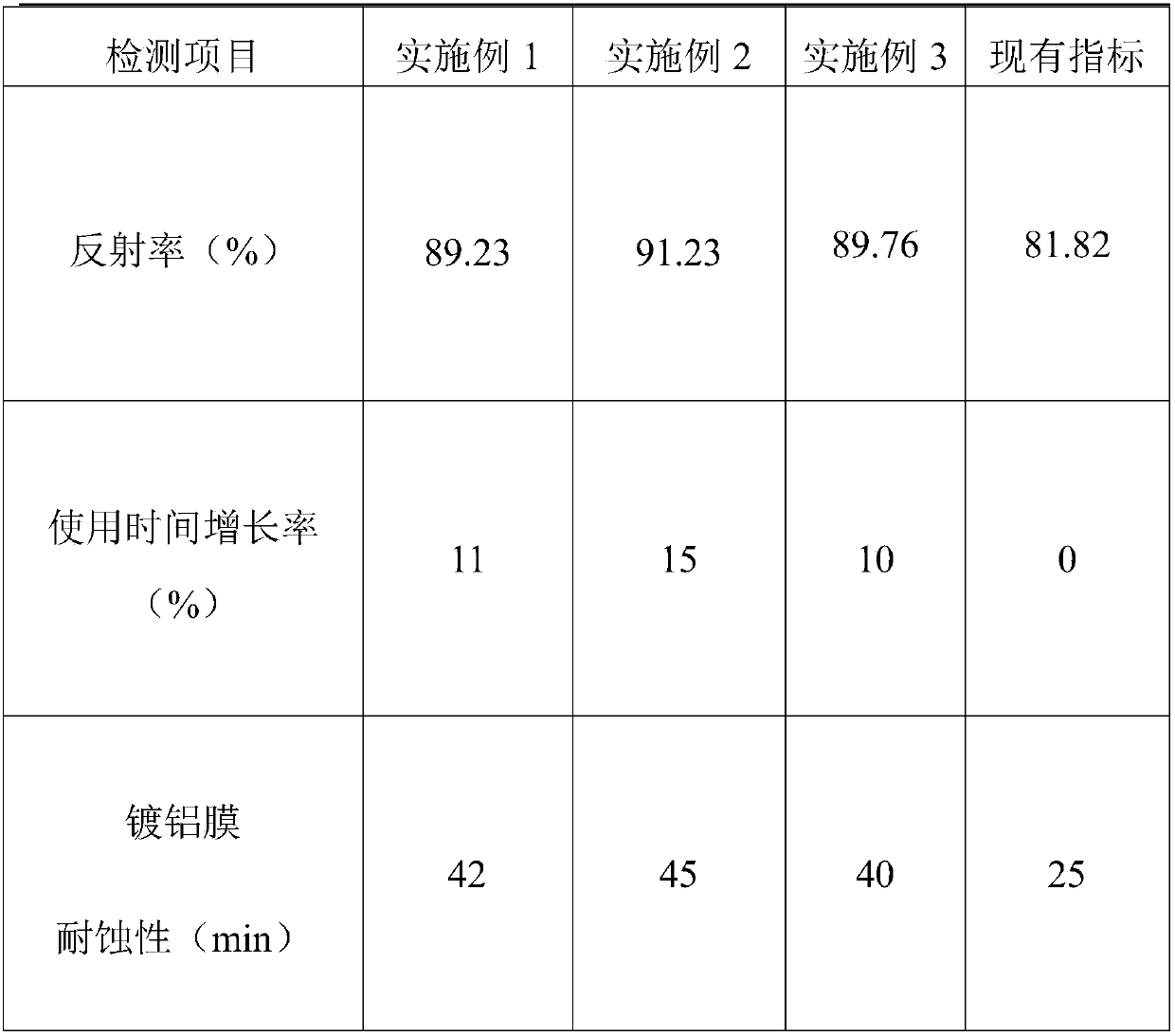

Examples

Embodiment 1

[0036] A coating process for automotive lamps, comprising the steps of:

[0037] (1) dry

[0038] The polyethylene terephthalate and silicon dioxide particles are dried in a dryer, the temperature of the dryer is 80° C., and the drying time is 8 hours. The polyethylene terephthalate and the mass fractions of silicon dioxide particles are 40% and 60% respectively;

[0039] (2) mixed

[0040] Centrifugally mix the dried polyethylene terephthalate, silicon dioxide particles, and simethicone emulsifier in a centrifuge to form a mixture, and the time for the centrifugal mixing is 15 minutes;

[0041] (3) Reaction

[0042] Put the mixed material into the polymerization reactor to make it react, and the reaction time is 20min;

[0043] (4) extrusion

[0044] Feed the reacted material to the extrusion feeder for feeding, and then feed it to the twin-screw extruder for extrusion and granulation to obtain mixed granules;

[0045] (5) Calendering

[0046] The mixed particles and P...

Embodiment 2

[0060] A coating process for automotive lamps, comprising the steps of:

[0061] (1) dry

[0062] The polyethylene terephthalate and silicon dioxide particles are dried in a dryer, the temperature of the dryer is 90° C., and the drying time is 10 hours. The polyethylene terephthalate and the mass fractions of silicon dioxide particles are 60% and 40% respectively;

[0063] (2) mixed

[0064] Centrifugally mix the dried polyethylene terephthalate, silicon dioxide particles, and simethicone emulsifier in a centrifuge to form a mixture, and the time for the centrifugal mixing is 20 minutes;

[0065] (3) Reaction

[0066] Put the mixed material into the polymerization reactor to make it react, and the reaction time is 30min;

[0067] (4) extrusion

[0068] Feed the reacted material to the extrusion feeder for feeding, and then feed it to the twin-screw extruder for extrusion and granulation to obtain mixed granules;

[0069] (5) Calendering

[0070] The mixed particles and ...

Embodiment 3

[0084] A coating process for automotive lamps, comprising the steps of:

[0085] (1) dry

[0086] The polyethylene terephthalate and silicon dioxide particles are dried in a dryer, the temperature of the dryer is 100°C, and the drying time is 12h. The polyethylene terephthalate and the mass fractions of silicon dioxide particles are 80% and 20% respectively;

[0087] (2) mixed

[0088] The dried polyethylene terephthalate, silicon dioxide particles and simethicone emulsifier are centrifugally mixed in a centrifuge to form a mixture, and the time of the centrifugal mixing is 25 minutes;

[0089] (3) Reaction

[0090] Put the mixed material into the polymerization reactor to make it react, and the reaction time is 40min;

[0091] (4) extrusion

[0092] Feed the reacted material to the extrusion feeder for feeding, and then feed it to the twin-screw extruder for extrusion and granulation to obtain mixed granules;

[0093] (5) Calendering

[0094] The mixed granules and PET...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com