Mixed powder for iron-based powder metallurgy, method for producing same, sintered body produced using same, and method for producing sintered body

A technology of iron-based powder metallurgy and manufacturing method, applied in the field of iron-based powder metallurgy at the end of use, can solve the problems of sintered body pollution, reduced strength of mechanical parts, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

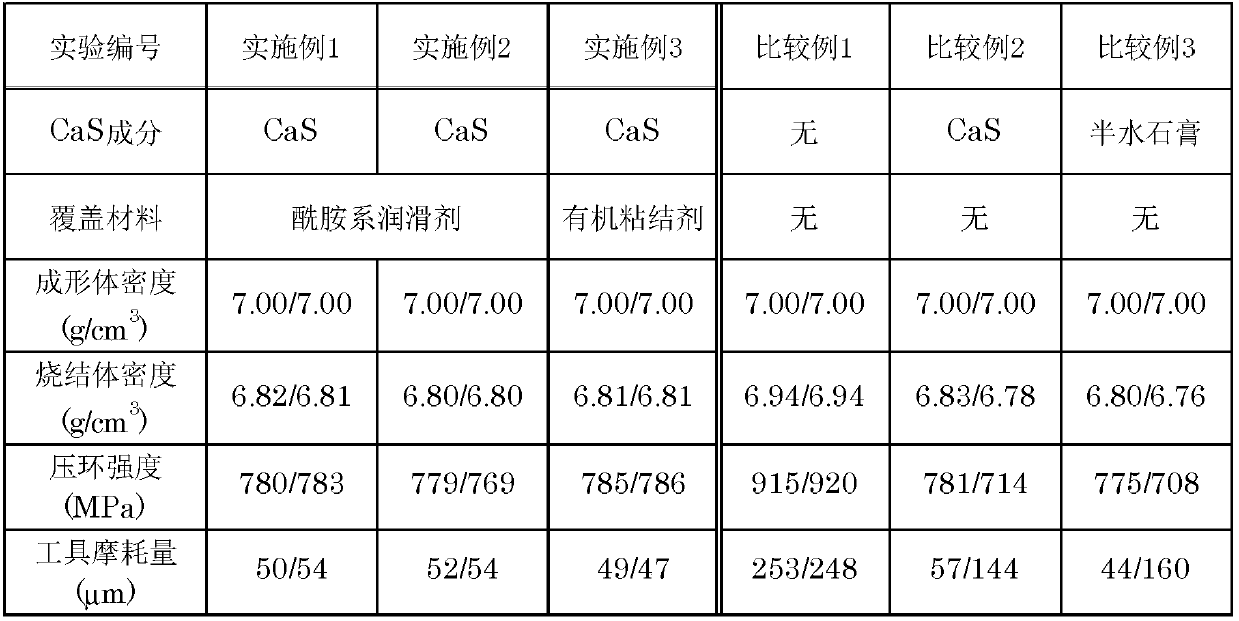

Examples

Embodiment 1

[0082] First, commercially available calcium sulfide powder was classified at −63 / +45 μm (volume average particle size: 54 μm) with a sieve. The graded calcium sulfide powder is added into the airtight container according to the weight of the sintered CaS to reach 0.5% by weight. 0.75% by weight of an amide-based lubricant (product name: ACRAWAX C (manufactured by LONZA)) was added to this airtight container. Then, the mixture was mixed for 10 minutes while heating to 100° C., thereby covering the surface of the calcium sulfide powder with the amide-based lubricant.

[0083] Then, 2% by weight of copper powder (product name: CuATW-250 (manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.)), 0.8 Graphite powder (product name CPB (manufactured by Nippon Graphite Industry Co., Ltd.)) by weight % and the calcium sulfide powder covered with the lubricant prepared above were used to prepare a mixed powder for iron-based powder metallurgy. In addition, the said graphite powd...

Embodiment 2

[0085] In Example 1, calcium sulfide powder and amide-based lubricant (product name: ACRAWAX C (manufactured by LONZA)) were added to an airtight container and heated to 100°C, while in Example 2, the The powders of all the components were put into an airtight container, heated to 100° C. by a hot melt method, and mixed for 30 minutes, thereby covering the surface of the powders of all the components with the amide-based lubricant. Then it was cooled to room temperature, thereby producing mixed powder for iron-based powder metallurgy.

Embodiment 3

[0087] In Example 3, the same powders as in Example 2 were mixed except that the amide-based lubricant used in Example 2 was replaced with a toluene solution containing styrene-butadiene rubber. The toluene solution was added so that the weight of the styrene-butadiene rubber after toluene volatilization became 0.1% by weight. Then, toluene was volatilized at 100° C., thereby covering the surface of the CaS raw material particles with styrene-butadiene rubber. Then, the amide-based lubricant used in Example 1 was added and mixed in an amount equivalent to that used in Example 1, to prepare the mixed powder for iron-based powder metallurgy of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com