Preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering

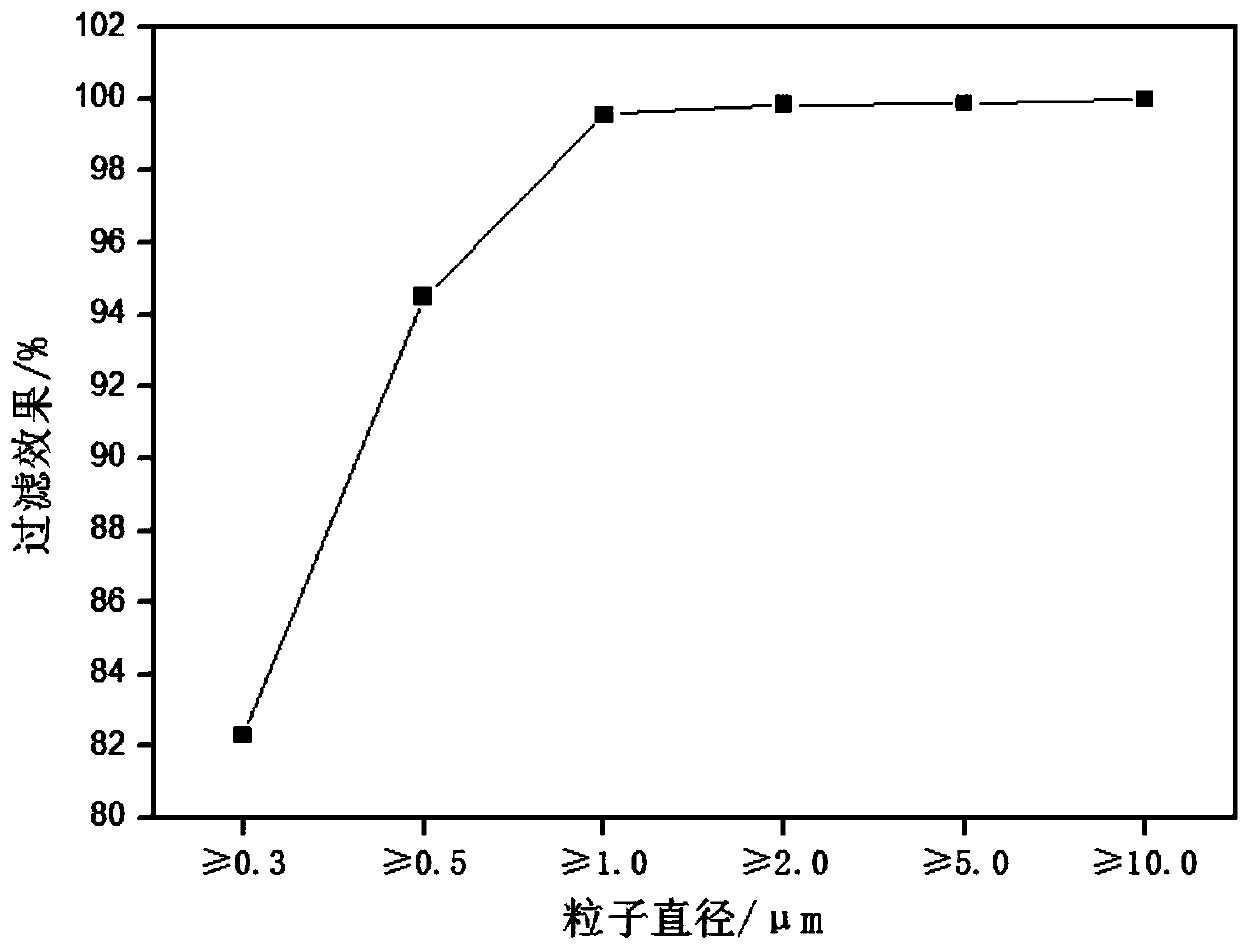

The technology of non-woven fabric and cotton stalk skin is applied in the field of preparation of cotton stalk skin fiber and chitosan composite non-woven fabric for filtration, which can solve the problems of complex electrospinning process, unsuitable for industrialization, and not easy to degrade, etc. The effect of mechanical properties and filtration efficiency, reducing damage and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) cutting: the cotton stalk bark is cut into 1.5cm fragments;

[0061] (2) Soaking: put the cut cotton stalk skin in clear water with a liquor ratio of 1:15, and soak for 2 hours at a water temperature of 80°C;

[0062] (3) Fractional flash explosion: put the soaked cotton stalks into the flash explosion material bin, inject saturated water vapor, make the saturated water vapor pressure reach 2MPa, maintain the saturated water vapor pressure for 60s and then flash explosion; repeat this flash Burst step, burst 3 times;

[0063] (4) Cleaning: the cotton stalk skin fiber after the flash explosion is cleaned 5 times at room temperature to remove massive impurities;

[0064] (5) Beating: adopt frequency modulation beater to beat, control the slurry concentration to be 60%, after dispersing for 5 minutes, beat for 15 minutes;

[0065] (6) Manufacture: Weigh 4g of the slurry that has been beaten and dried to dryness, add water to 2L, and then use a decomposer to decompose...

Embodiment 2

[0074] (1) cutting: the cotton stalk bark is cut into 2cm fragments;

[0075] (2) Soaking: put the cut cotton stalk skin in clear water with a liquor ratio of 1:20, and soak for 3 hours at a water temperature of 75°C;

[0076] (3) Fractional flash explosion: put the soaked cotton stalks into the flash explosion material bin, feed saturated water vapor, make the saturated water vapor pressure reach 1.5MPa, maintain the saturated water vapor pressure for 60s and then flash explosion; repeat this process Flash explosion step, explode 3 times;

[0077] (4) Cleaning: the cotton stalk skin fiber after the flash explosion is cleaned 5 times at room temperature to remove massive impurities;

[0078] (5) Beating: adopt frequency modulation beater to beat, control the slurry concentration to be 60%, after dispersing for 5 minutes, beat for 20 minutes;

[0079] (6) Manufacture: Weigh 5g of the pulp that has been beaten and dried to dryness, add water to 2L, and then use a decomposer to...

Embodiment 3

[0087] (1) cutting: the cotton stalk bark is cut into 2cm fragments;

[0088] (2) Soaking: put the cut cotton stalk skin in clear water with a liquor ratio of 1:30, and soak for 3 hours at a water temperature of 70°C;

[0089] (3) Fractional flash explosion: put the soaked cotton stalks into the flash explosion material bin, inject saturated water vapor, make the saturated water vapor pressure reach 2MPa, maintain the saturated water vapor pressure for 60s and then flash explosion; repeat this flash Burst step, burst 3 times;

[0090] (4) Cleaning: the cotton stalk skin fiber after the flash explosion is cleaned 5 times at room temperature to remove massive impurities;

[0091] (5) Beating: use a frequency modulation beating machine to beat, control the concentration of the slurry to less than 60%, and after dispersing for 5 minutes, beat for 10 minutes;

[0092] (6) Manufacture: Weigh 2 g of the slurry that has been beaten and dried to dryness, add water to 2 L, and then us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com