A method for preparing c/c-cu composite material by cu-mo mixed impregnation

A composite material, cu-mo technology, applied in the field of metal impregnation carburizing/carbon composite material, can solve the problems of poor wettability of copper and carbon interface, achieve good compactness, improve poor interface wettability, and improve interface The effect of poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

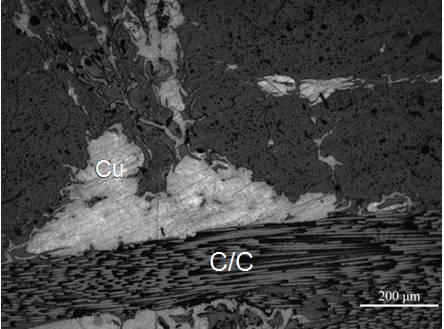

Image

Examples

Embodiment 1

[0020] A method for preparing C / C-Cu composite material by mixed impregnation of Cu-Mo, the steps are as follows:

[0021] (1) Carbon fiber needle-punched felt is used as the prefabricated body, and the density is 1.1g / cm3 prepared by chemical vapor infiltration process 3 C / C porous body;

[0022] (2), after mixing Mo powder and Cu powder, in N 2 Ball milling in a high-energy ball mill under protection for 24 hours; the mass ratio of the Cu powder to the Mo powder is 10:1, and the mass of the Cu powder is 1.5 times that of the C / C porous body;

[0023] (3) Embed the C / C porous body obtained in step (1) in the mixed powder obtained in step (2), and put it into a graphite crucible; place the graphite crucible in a high-temperature graphitization furnace for heat treatment under the protection of an inert atmosphere , carry out infiltration Cu reaction, the heating rate is 5°C / min, first keep at 1000°C for 2h, then at 1250°C for 2h, and then cool down with the furnace;

[0024...

Embodiment 2

[0027] A method for preparing C / C-Cu composite material by mixed impregnation of Cu-Mo, the steps are as follows:

[0028] (1) Carbon fiber needle-punched felt is used as the prefabricated body, and the density is 1.3g / cm3 prepared by chemical vapor infiltration process 3 C / C porous body;

[0029] (2), after mixing Mo powder and Cu powder, in N 2 Ball milling in a high-energy ball mill under protection for 16 hours; the mass ratio of the Cu powder to the Mo powder is 9:1, and the mass of the Cu powder is 1.4 times that of the C / C porous body;

[0030] (3) Embed the C / C porous body obtained in step (1) in the mixed powder obtained in step (2), and put it into a graphite crucible; place the graphite crucible in a high-temperature graphitization furnace for heat treatment under the protection of an inert atmosphere , carry out the infiltration Cu reaction, the heating rate is 10°C / min, first hold at 1100°C for 1.5h, then hold at 1200°C for 1.5h, and then cool down with the furn...

Embodiment 3

[0034] A method for preparing C / C-Cu composite material by mixed impregnation of Cu-Mo, the steps are as follows:

[0035] (1) Carbon fiber needle-punched felt is used as the prefabricated body, and the density is 1.4g / cm3 prepared by chemical vapor infiltration process 3 C / C porous body;

[0036] (2), after mixing Mo powder and Cu powder, in N 2 Ball milling in a high-energy ball mill under protection for 12 hours; the mass ratio of the Cu powder to the Mo powder is 8:1, and the mass of the Cu powder is 1.3 times that of the C / C porous body;

[0037] (3) Embed the C / C porous body obtained in step (1) in the mixed powder obtained in step (2), and put it into a graphite crucible; place the graphite crucible in a high-temperature graphitization furnace for heat treatment under the protection of an inert atmosphere , carry out the infiltration Cu reaction, the heating rate is 10°C / min, first hold at 900°C for 1 hour, then hold at 1300°C for 1 hour, and then cool down with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com