Core-shell structure nanocrystal and preparation method thereof

A nanocrystal and shell structure technology, applied in nanotechnology, nanooptics, nanotechnology, etc., can solve the problems of low quantum yield and poor optical stability, and achieve the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

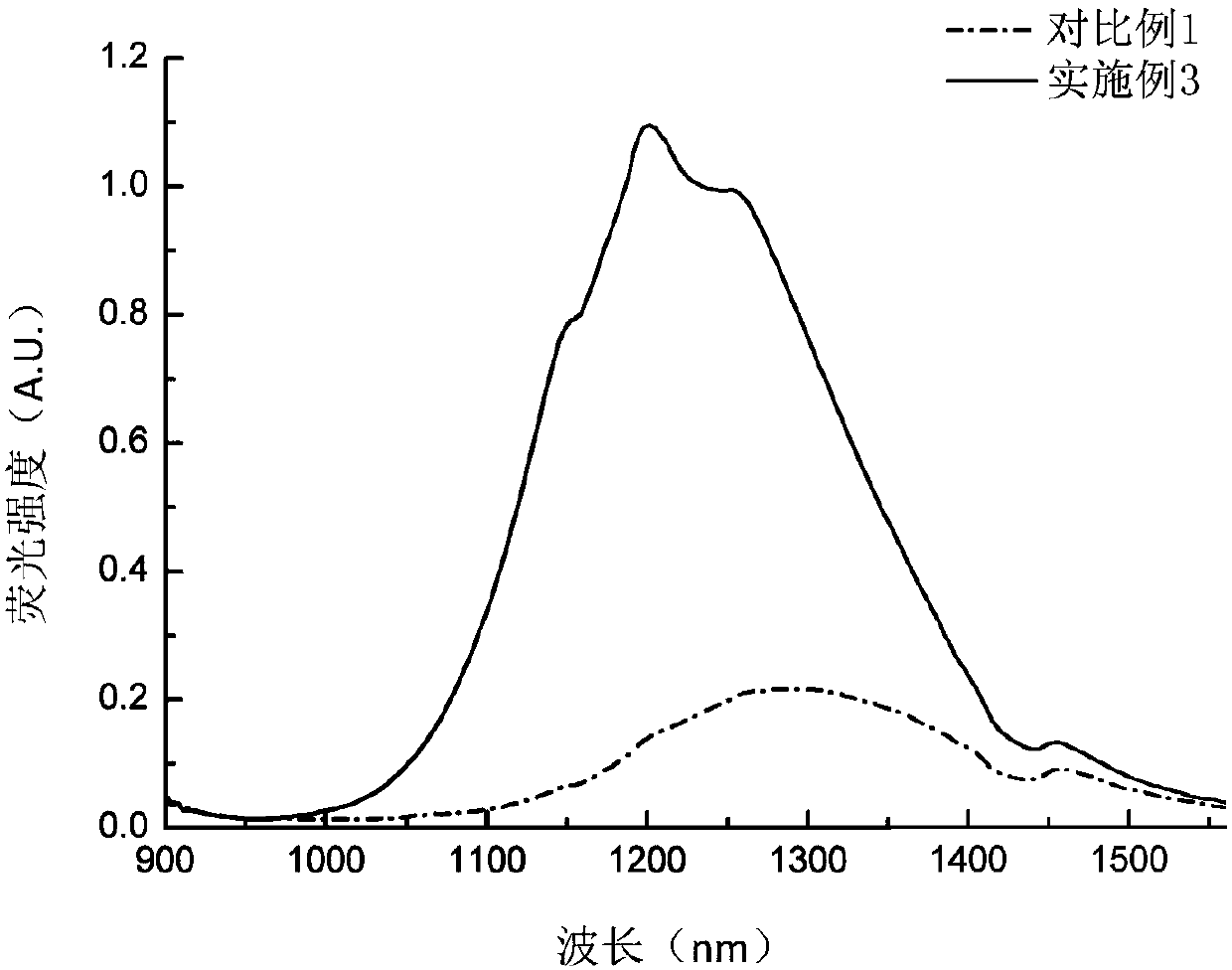

Examples

preparation example Construction

[0029] In another typical embodiment of the present invention, a method for preparing nanocrystals with a core-shell structure is provided, including the following process: Step 1, preparing nanocrystal cores in the oil phase; step 2, adding The first zinc precursor, the Zn element in the first zinc precursor exchanges the Ag element in the nanocrystal core by cations, and obtains the Zn-doped first shell layer coated on the outside of the nanocrystal core; step 3, in the first shell The outer layer is covered with the second shell layer; wherein, the composition of the nanocrystalline core is Ag 2 S, the composition of the first shell is Zn x Ag 2(1-x) S, the composition of the second shell layer is ZnS, where 0<x<1.

[0030] Step 1 is the preparation process of the nanocrystalline core, compared to the aqueous phase synthesis of Ag 2 S nanocrystal nuclei, the oil phase can provide a higher reaction temperature, thereby increasing the nucleation rate and crystallinity of n...

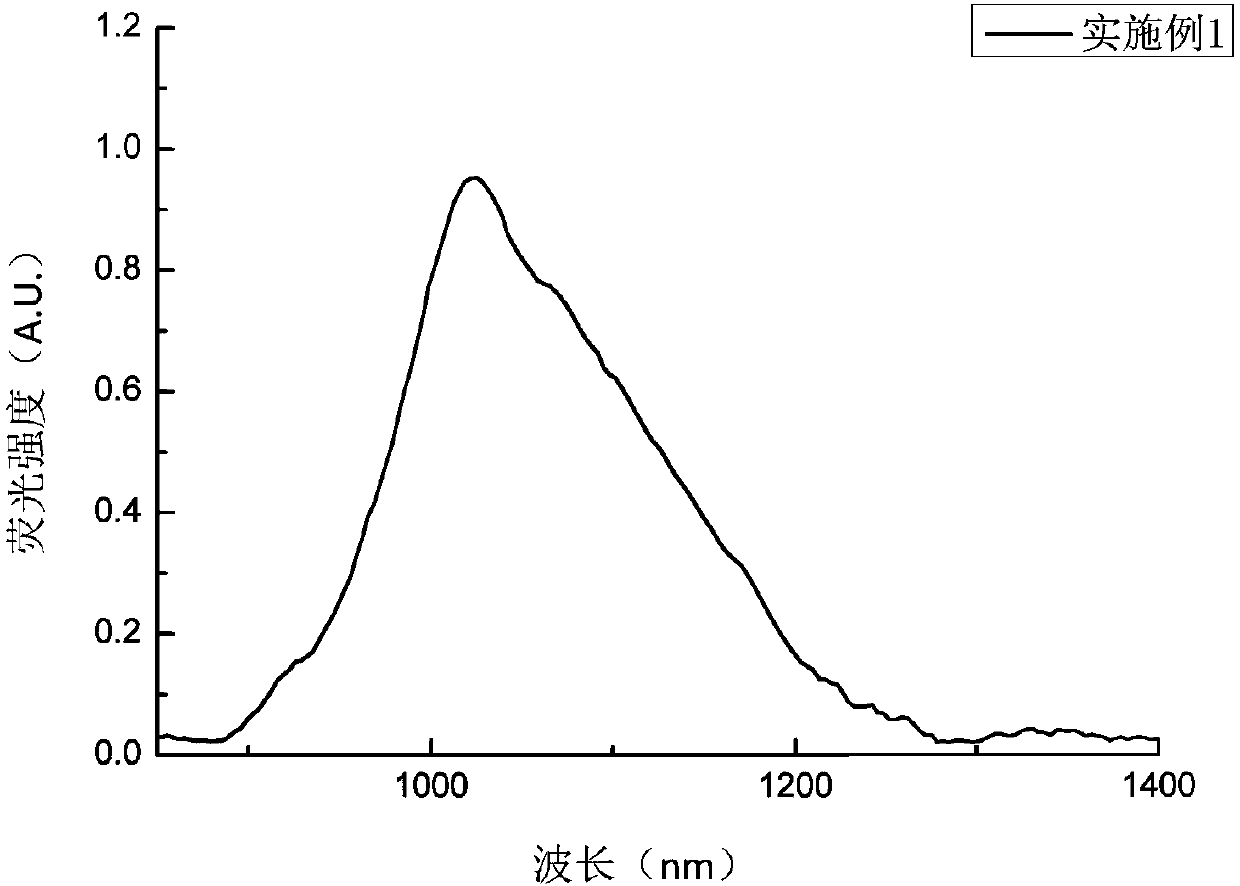

Embodiment 1

[0049] (1) Step 1: Prepare nanocrystalline nuclei in the oil phase:

[0050] Add 170 mg of silver nitrate, 1 ml of oleic acid, 10 ml of n-dodecanethiol, and 30 ml of octadecene into a 100 ml three-necked flask, stir and remove water and oxygen to form a solution containing Ag ions.

[0051] Mix the S powder with the oleylamine solution, stir to dissolve the S powder, and obtain a S precursor solution with a concentration of 1M. At 130 degrees Celsius, 500 microliters of S precursor solution was hot injected into the solution containing Ag ions, and reacted for 10 minutes to obtain Ag 2 S nanocrystalline core.

[0052] (2) Step 2: Diethyl zinc and octadecene were mixed to obtain a diethyl zinc octadecene solution with a concentration of 1M. At 130 °C, hot inject 0.2 ml of diethyl zinc octadecene solution into the Ag 2 In the solution of S nanocrystal nuclei, react for 30min, and get coated in Ag 2 Zn outside the core of S nanocrystals x Ag 2(1-x) S first shell.

[0053] ...

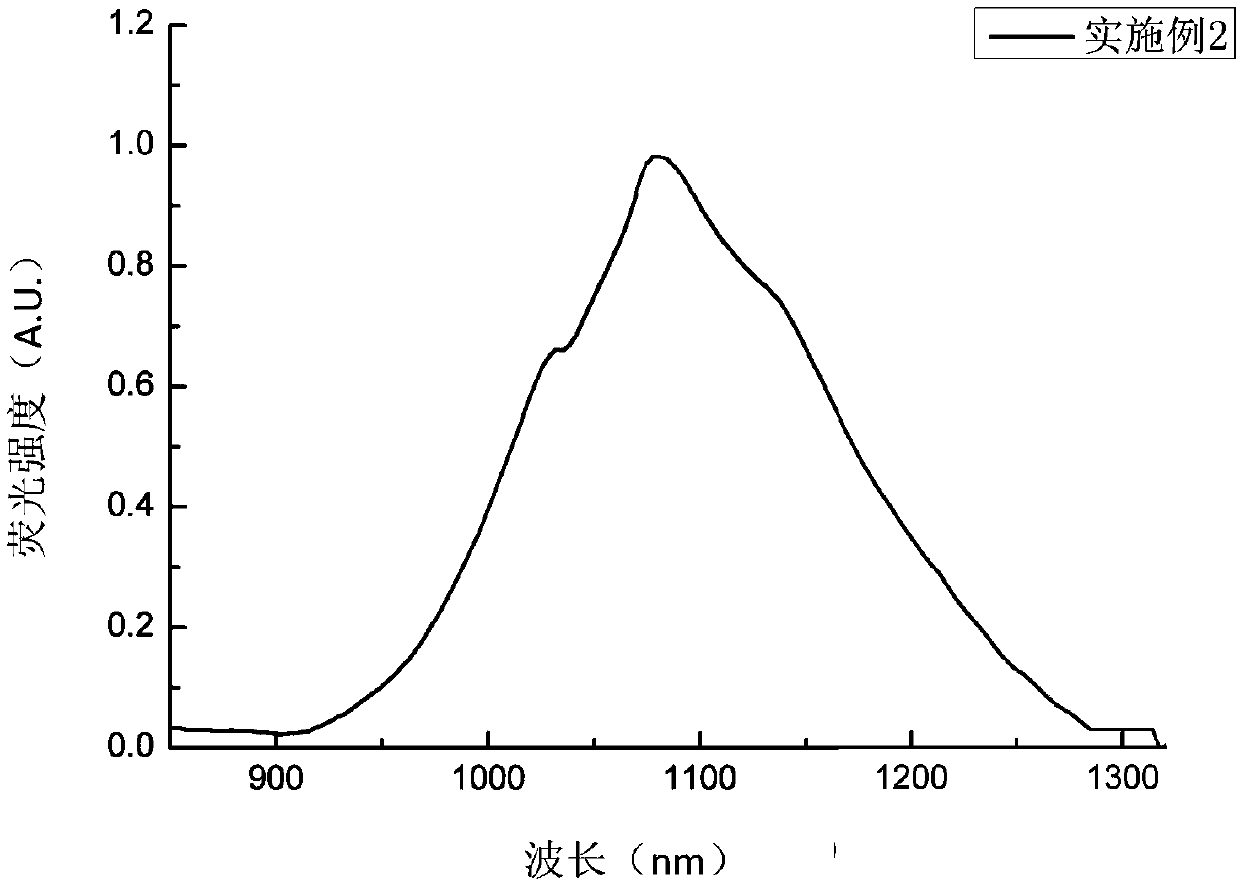

Embodiment 2

[0055] (1) Step 1: Prepare nanocrystalline nuclei in the oil phase:

[0056] Add 170 mg of silver nitrate, 1 ml of oleic acid, 10 ml of n-dodecanethiol, and 30 ml of octadecene into a 100 ml three-necked flask, stir and remove water and oxygen to form a solution containing Ag ions.

[0057] Mix the S powder with the oleylamine solution, stir to dissolve the S powder, and obtain a S precursor solution with a concentration of 1M. At 130 degrees Celsius, 500 microliters of S precursor solution was hot injected into the solution containing Ag ions, and reacted for 10 minutes to obtain Ag 2 S nanocrystalline core.

[0058] (2) Step 2: Diethyl zinc and octadecene were mixed to obtain a diethyl zinc octadecene solution with a concentration of 1M. At 140 °C, hot inject 0.2 ml of diethyl zinc octadecene solution into the Ag 2 In the solution of S nanocrystal nuclei, react for 30min, and get coated in Ag 2 Zn outside the core of S nanocrystals x Ag 2(1-x) S first shell.

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com