Preparation method of crosslinked polyethylene electric-conductive foam material

A technology for cross-linking polyethylene and foaming materials, applied in the field of conductive foaming materials, can solve the problems of high addition of conductive carbon black, not improving dispersion and resistivity, affecting the conductivity and mechanical properties of materials, etc. The effect of small inter-action force, reduction of secondary mixing difficulty, and easy combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

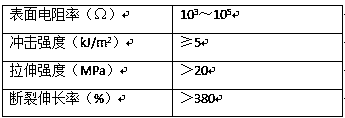

Examples

Embodiment 1

[0026] A method for preparing a cross-linked polyethylene conductive foaming material, comprising the following steps: (1) Weighing 5% azodicarbonamide, 0.1% conductive carbon black, 2% calcium carbonate, 0.1% antioxidant 1010, 0.1 % zinc stearate and 2% masterbatch 1398, respectively diluted with low-density polyethylene, the amount of low-density polyethylene is 10%, 0.5%, 4%, 0.2%, 0.15%, 3%, through the twin-screw Extrusion granulation by extruder, twin-screw extruder extrusion temperature 110°C; (2) Weigh 72.85% low-density polyethylene and mix evenly with the granules prepared in step (1); (3) Mix the mixed materials , extruded into sheets by a single-screw extruder and wound up. The process conditions of the single-screw extruder are: the temperature of the first zone is 150°C, the temperature of the second zone is 140°C, the temperature of the third zone is 120°C, and the temperature of the fourth zone is 110°C. The temperature in the fifth zone is 100°C, the temperatu...

Embodiment 2

[0028] A method for preparing a cross-linked polyethylene conductive foaming material, comprising the following steps: (1) Weighing 7% azodicarbonamide, 0.2% conductive carbon black, 2.5% calcium carbonate, 0.5% antioxidant 1010, 0.5 % zinc stearate and 2% masterbatch 1398, respectively diluted with low-density polyethylene, the amount of low-density polyethylene corresponding to 11.2%, 1%, 3.75%, 0.8%, 0.75%, 3%, through the twin-screw Extrusion granulation by extruder, extrusion temperature of twin-screw extruder 120°C; (2) Weigh 66.8% low-density polyethylene and mix evenly with the granules prepared in step (1); (3) Mix the mixed materials , extruded into a sheet by a single-screw extruder and wound up. The process conditions of the single-screw extruder are: the temperature of the first zone is 150°C, the temperature of the second zone is 145°C, the temperature of the third zone is 120°C, and the temperature of the fourth zone is 105°C. The temperature in the fifth zone i...

Embodiment 3

[0030] A method for preparing a cross-linked polyethylene conductive foaming material, comprising the following steps: (1) Weighing 10% azodicarbonamide, 0.3% conductive carbon black, 2.8% calcium carbonate, 1% antioxidant 1010, 0.5 % zinc stearate and 2.4% masterbatch 1398, respectively diluted with low-density polyethylene, the amount of low-density polyethylene is 15%, 1.5%, 4.2%, 1.6%, 0.8%, 3.6%, through the twin-screw Extrusion granulation by extruder, twin-screw extruder extrusion temperature 120°C; (2) Weigh 56.3% low-density polyethylene and mix evenly with the granules prepared in step (1); (3) Mix the mixed materials , extruded into sheets by a single-screw extruder and wound up. The process conditions of the single-screw extruder are: the temperature of the first zone is 155°C, the temperature of the second zone is 145°C, the temperature of the third zone is 125°C, and the temperature of the fourth zone is 110°C. The temperature in the fifth zone is 105°C, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com