Photosensitive crosslinking agent and preparation method and application thereof

A cross-linking agent and photosensitive technology, which can be used in the preparation of carboxylic acid halides, chemical instruments and methods, luminescent materials, etc., and can solve the problems of low cross-linking efficiency and small number of chromophores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

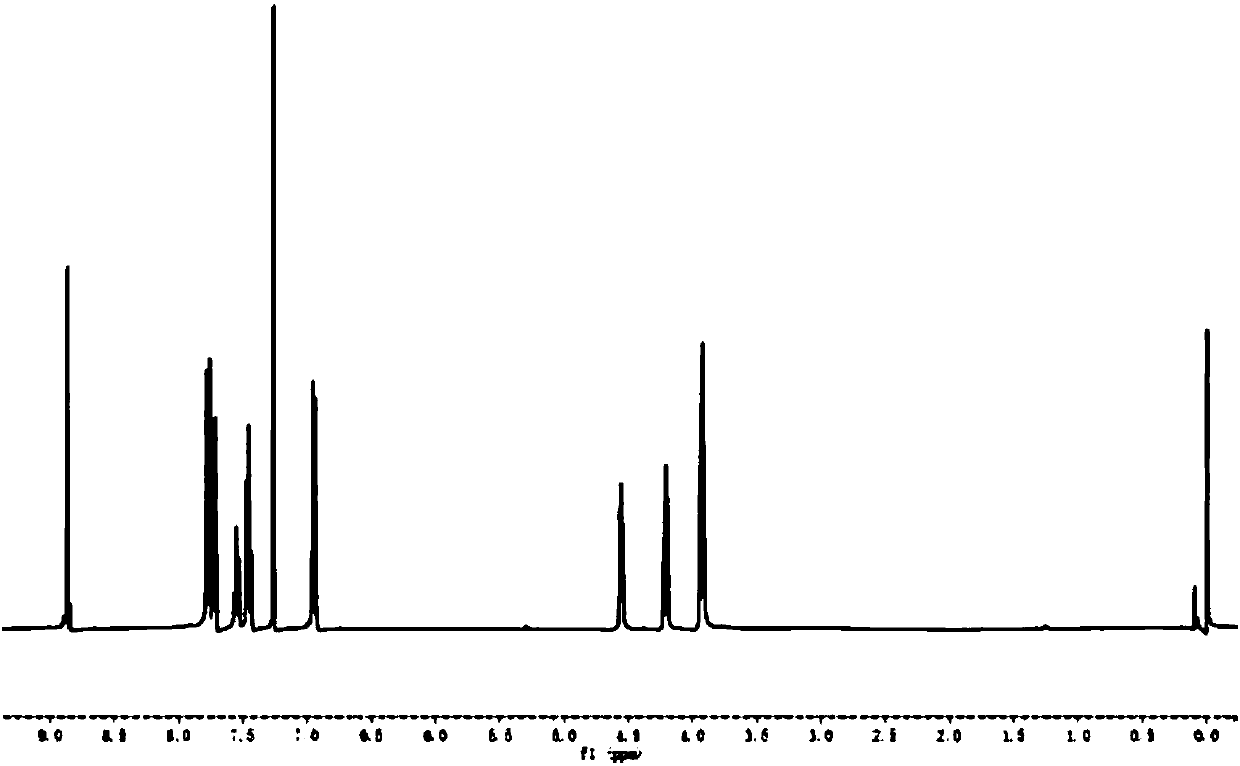

Image

Examples

preparation example Construction

[0056] The preparation method of the photosensitive cross-linking agent of embodiment 1, three branches

[0057] This example provides a preparation method for a three-branched photosensitive crosslinking agent, and its synthetic route can be found in figure 1 . The structural formula of the three-branched photosensitive crosslinking agent containing active carbonyl is as follows,

[0058]

[0059] The preparation method is as follows: add 4-hydroxybenzophenone (4.7572g, 24.0mmol), 2-(2-chloroethoxy)ethanol (3.7371g, 30.0mmol) and potassium carbonate (6.6240g, 48.0mmol) In 10mL N,N-dimethylformamide, react at 120°C for 8-10 hours. After the reaction, 100 mL of distilled water was added into the reaction system, extracted with anhydrous ether, washed with saturated brine, dried over anhydrous magnesium sulfate, and then rotary-evaporated to obtain an intermediate product. Dissolve 1,3,5-benzenetricarboxylic acid chloride (0.8495g, 3.76mmol) in 30mL of dichloromethane, c...

Embodiment 3

[0070] Embodiment 3, formula III Preparation method of photosensitive crosslinking agent

[0071] This embodiment provides the preparation method of the photosensitive cross-linking agent of the formula III structure, and its preparation method is basically the same as that of Example 2, the only difference is: the reaction amount of chlorine p-toluenesulfonate and dipentaerythritol used in this embodiment Configure according to its molar ratio of 7:1; the reaction amount of the intermediate product and 4-hydroxybenzophenone is configured according to its molar ratio of 1:7. That is, the target product shown in the following structure is obtained:

[0072]

Embodiment 4

[0073] Embodiment 4, cross-linked polymethacrylate material and its film properties and insulating properties

[0074] The cross-linking agent used in this example is the three-branched photosensitive cross-linking agent prepared in Example 1, blended with polymethyl methacrylate or polyisobutyl methacrylate, polymethacrylate materials and The weight ratio of crosslinking agent is 20:1. The mixed solution (dichloromethane solvent) was spin-coated on silicon wafers for infrared characterization. The insulation properties of cross-linked polymethacrylate materials can be obtained through MIM devices. Its preparation method ( Figure 16 ) is: a layer of 40nm thick aluminum metal layer is evaporated on the glass substrate as an electrode, and the polymethacrylate material and the three-branched photosensitive cross-linking agent are mixed with chlorobenzene solution at room temperature for 12 hours, and spin Apply to glass substrates. Then the radiant energy is 7000mW / cm at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com